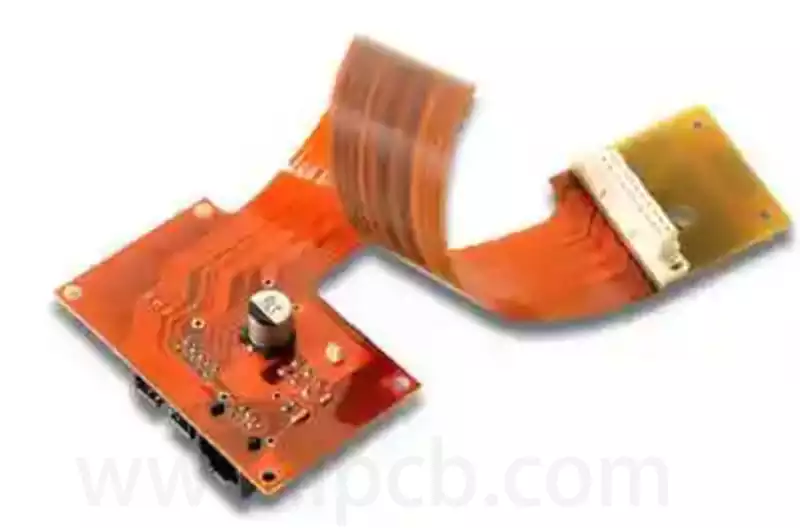

In today’s era of increasingly miniaturised and multifunctional electronic devices, flexible printed circuits (FPC) have become vital bridges connecting critical internal components. However, as technological aesthetics and application scenarios continue to expand, a novel type of flexible circuit board—the transparent flexible printed circuit (Transparent FPC)—is emerging. It not only inherits the flexibility of traditional FPC but also incorporates transparency, opening new possibilities for electronic design. This article aims to delve into the specific differences between transparent FPC and conventional FPC, covering their material composition, internal structure, performance characteristics, and respective application domains. This analysis seeks to clarify how these two technologies collectively propel the advancement of the modern electronics industry.

Comparative Analysis of Transparent FPC and Standard FPC

Material Differences

Transparent FPC employs high-transmittance PET film as its substrate. This PET film achieves over 85% light transmittance, imparting a crystalline, translucent aesthetic to the product with a distinctly futuristic visual appeal. It also exhibits excellent high-temperature resistance, withstanding temperatures up to 200°C, thereby meeting diverse lamination and soldering process requirements.

Conventional FPCs, however, employ traditional PI (polyimide) film as their substrate. PI substrates exhibit relatively low light transmittance and are commonly available in colours such as yellow, black, and white. Nevertheless, they possess outstanding mechanical properties and high-temperature resistance, capable of withstanding temperatures up to 280°C. Consequently, conventional FPCs remain the mainstream choice in traditional application areas such as consumer electronics and automotive electronics.

Structural Differences

From a structural lamination perspective, transparent FPCs and conventional FPCs exhibit distinct differences.

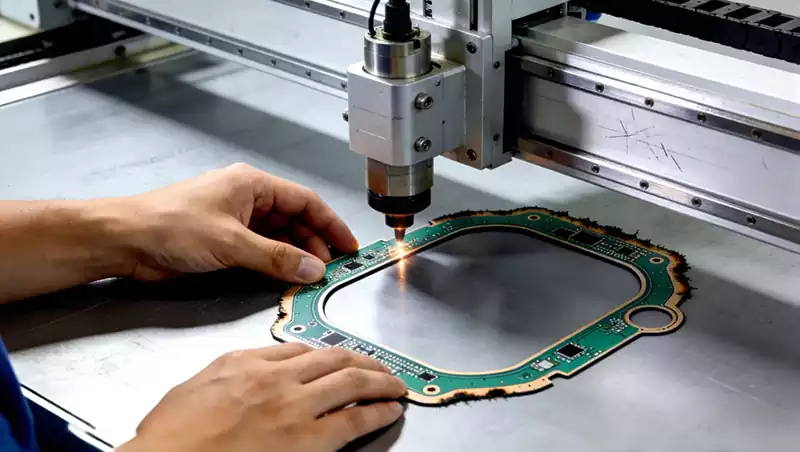

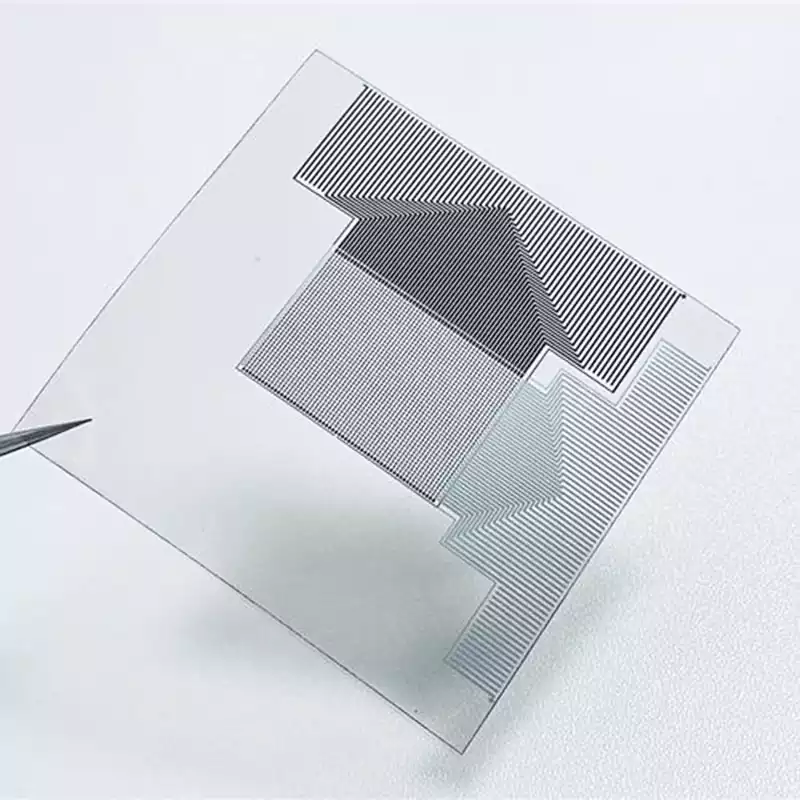

Transparent FPCs incorporate an additional adhesive layer within their structure. This layer primarily ensures a robust bond between the PET substrate and copper foil. Specifically, the structure of a transparent FPC is: PET substrate → adhesive layer → copper foil → cover film.

Conventional FPCs feature a simpler structure: PI substrate → copper foil → cover film.

This structural variation presents greater manufacturing challenges for transparent FPCs. However, it is precisely this configuration that enables transparent FPCs to achieve both high light transmission and exceptional flexibility.

Performance Comparison

Both transparent and conventional FPCs share common advantages, such as lightweight construction, bendability, and excellent conductivity. However, their primary focuses differ. Transparent FPCs prioritise meeting aesthetic and light transmission requirements, while conventional FPCs emphasise high-temperature tolerance and stability.

Application Domain Differences

Due to their distinct material properties, these two FPC types cater to different application domains.

Standard FPCs are primarily employed in conventional sectors such as mobile phones, tablets, computers, industrial control equipment, and automotive electronics. Products within these domains typically require stable signal transmission and high reliability, which standard FPCs effectively fulfil.

Transparent FPCs, conversely, are predominantly utilised in high-end applications requiring light transmission or visualisation windows, such as wearable medical devices, flexible displays, transparent touch modules, and optical sensors. Beyond functionality, they impart a visually striking technological aesthetic.

Transparent FPC not only enable flexible circuitry but also facilitate ‘optoelectronic integration’ with display, illumination, and sensing modules. Consequently, they are regarded as a pivotal development direction for future smart devices and flexible display technologies.

Transparent FPC and conventional FPC each possess distinct advantages in materials, structure, performance, and application domains. Complementing one another, they collectively provide robust support for the diversification and high performance of modern electronic products, propelling the electronics industry towards new developmental stages.