The production process for double sided pcb board consists of several stages, each of which may face a number of technical challenges.The following are some of the major challenges:

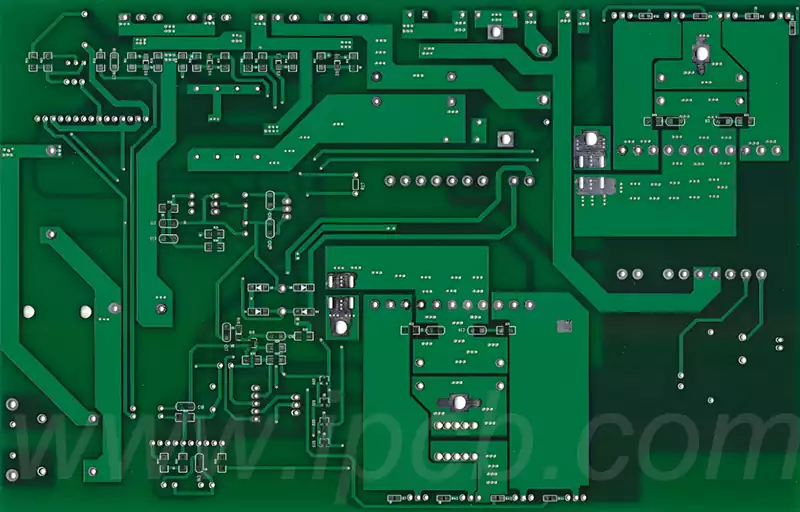

Design complexity:Double sided pcb board require circuitry to be laid out on two levels,which greatly increases the difficulty of the design.Designers must ensure that the circuits on both layers can be connected accurately and without error,while taking into account signal integrity and electromagnetic compatibility.

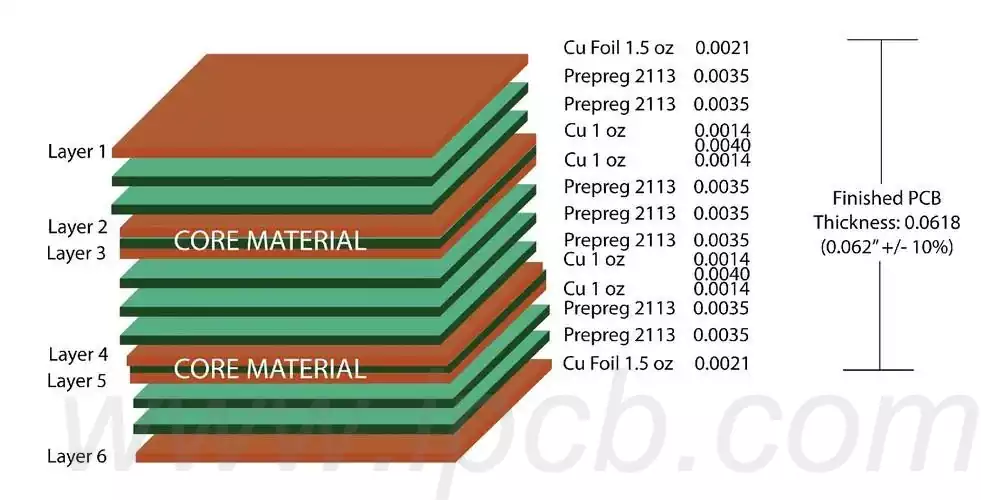

Precision of layer alignment:Ensuring the precise alignment of the top and bottom circuit patterns is a tricky issue during the manufacturing process.Any small deviation can lead to faulty circuit connections,which can affect the overall performance of the circuit.

Conductivity of via holes:Double sided pcb board require metallised via holes to connect the two layers of circuitry.The conductivity of these vias must be excellent or the electrical performance of the circuitry will be affected.The manufacture and metallisation of the through-holes is a critical part of the process.

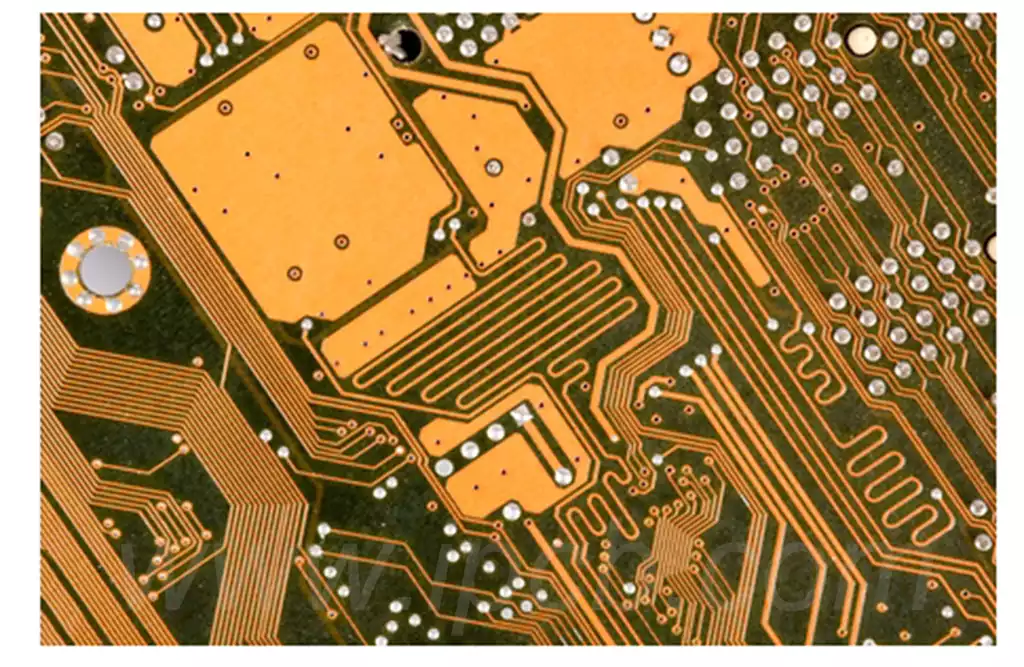

Accuracy of Etching:Etching is an important step in removing excess copper foil to form the desired circuit pattern.The accuracy of etching directly determines the quality and reliability of the circuit.The choice of etching solution,etching time control and post-etching treatment are all key factors affecting the accuracy of etching.

Accurate Printing of Soldermask:Soldermask is printed on double sided pcb board to protect copper foils from accidental short circuits or oxidation.The soldermask must be printed accurately so as not to interfere with the soldering and repair of circuits.

Accuracy of drilling and profile machining:The drilling and profile machining of double sided pcb board requires the use of high-precision equipment and processes to ensure that the position and size of the holes are accurate and the profile is regular.

Rigour of testing and inspection:Testing and inspection of double sided pcb board is a key step to ensure product quality.The electrical performance, mechanical performance and appearance of the circuit need to be thoroughly checked to ensure that the product meets the design requirements.

Rationality of material selection:The choice of substrate material has a crucial impact on the performance of double sided pcb board.Different substrates may have different effects on the signal transmission,thermal stability and mechanical strength of the circuit.

Compliance with Environmental Requirements:As environmental regulations continue to be strengthened,the manufacturing process of double sided pcb board must take into account the environmental friendliness of the materials as well as the disposal of waste generated during the production process.

Reasonable cost control:While ensuring product quality,it is also necessary to reasonably control production costs in order to enhance market competitiveness.This involves multiple levels of material procurement,production efficiency and process optimisation.