PCB circuit board prices are influenced by multiple factors, from materials and specifications to manufacturing processes and order volumes, each of which impacts the final price. Understanding these key elements is crucial for project budgeting and product competitiveness.

What are the key factors influencing PCB circuit board price?

PCB circuit board price is not arbitrarily determined but is shaped by a series of intricate technical and commercial factors. Consider it akin to a bespoke menu where every ‘ingredient’ you select directly impacts the final bill. From base materials to final testing, each stage plays a vital role. For any project manager or engineer undertaking electronic product development, a thorough understanding of these cost drivers is paramount.

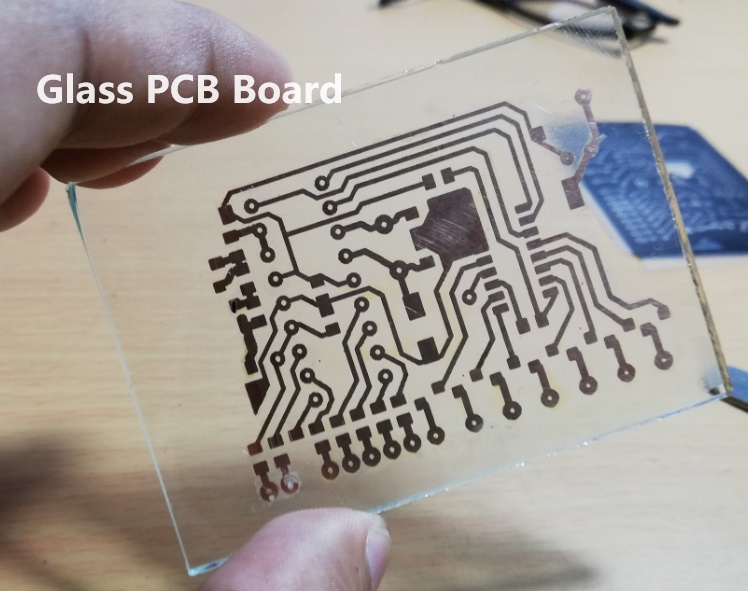

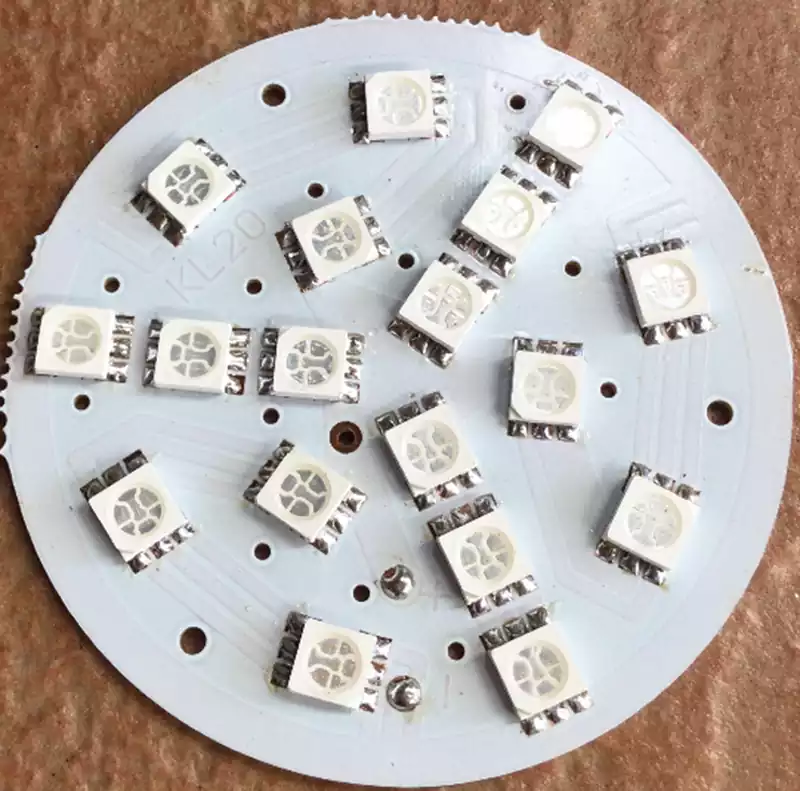

Material selection constitutes the most fundamental component of cost structure. The vast majority of PCBs utilise FR-4 (a glass-filled epoxy) as the substrate material, owing to its favourable balance between cost and performance. However, advanced applications requiring higher frequencies or superior thermal properties may necessitate more expensive specialty materials such as Rogers laminates or aluminium-clad boards. As highlighted in NextPCB’s analysis, a material’s temperature resistance, signal integrity, and mechanical properties all contribute to its price.

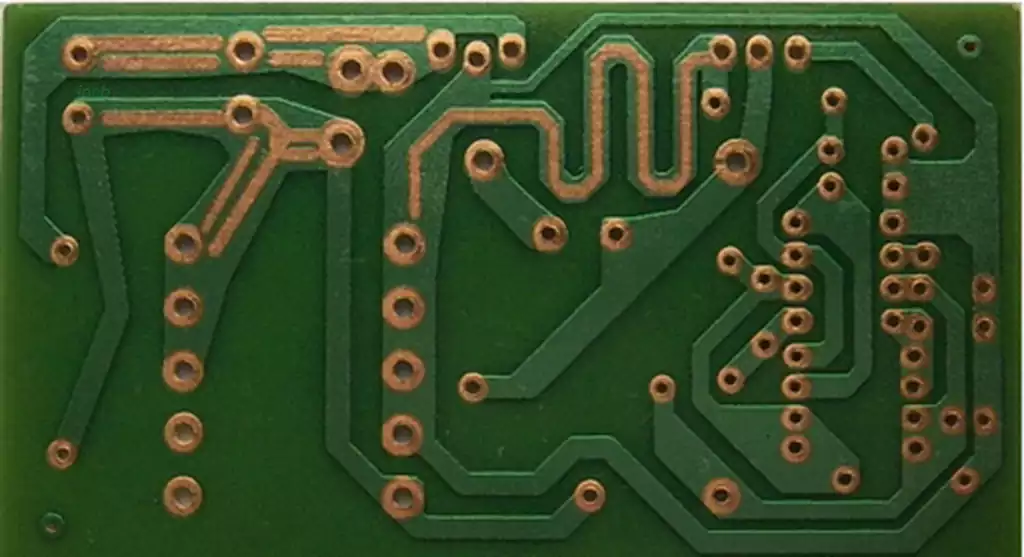

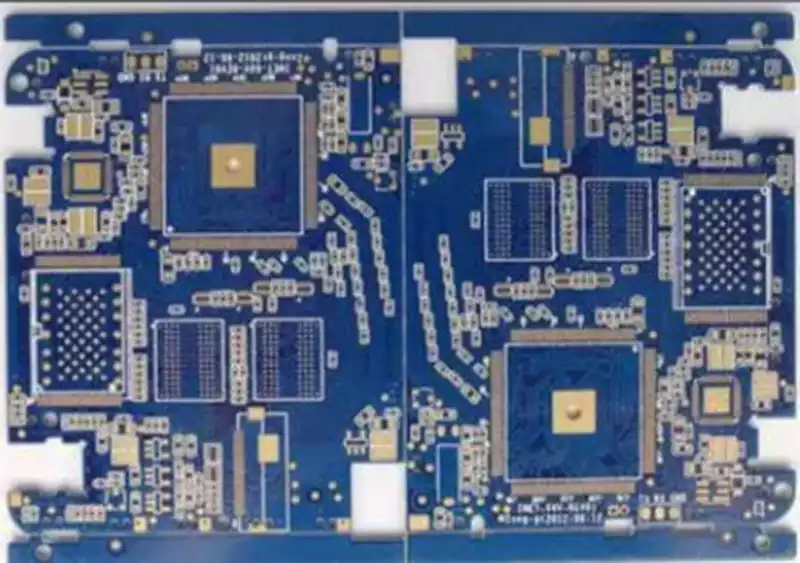

The physical specifications of a circuit board, such as its dimensions, number of layers, and thickness, are directly correlated with cost. Larger boards require more raw materials, naturally increasing expenses. The number of layers is another key cost driver. Moving from single-layer to double-layer boards, and further to more complex eight-layer or higher boards, each additional layer introduces more intricate manufacturing processes and higher material consumption. While costs do not increase exponentially, there is typically a significant rise of 30% to 40%.

Precision requirements during manufacturing also substantially elevate costs. These include copper weight (wire thickness), surface finish processes (such as HASL or ENIG gold fingers), and the precision and quantity of drilling. For instance, ENIG (electroless nickel immersion gold) is more costly than standard HASL (hot air solder level) but offers superior solderability and corrosion resistance. Similarly, smaller apertures and tighter tolerance requirements necessitate more advanced equipment and extended processing times, thereby driving up manufacturing costs.

Order volume and lead time are commercial factors determining unit cost. Larger orders yield lower unit costs due to economies of scale. Conversely, rush orders typically incur expedited fees as manufacturers must adjust production schedules or arrange overtime to meet urgent deadlines. Therefore, placing orders in advance and consolidating requirements where possible are effective strategies for controlling PCB circuit board prices during project planning.

Prototyping vs. Mass Production: What Are the Cost Differences?

Within the PCB manufacturing sector, a prevailing principle holds that the unit cost for small-batch prototyping significantly exceeds that of mass production. Many developers new to bespoke PCB solutions may be surprised by the high price of just a few sample boards, yet profound economic and engineering reasons underpin this. Understanding this cost disparity is crucial for project budgeting and selecting the appropriate manufacturing strategy.

The core difference lies in the allocation of Non-Recurring Engineering (NRE) costs. NRE refers to one-off expenditures incurred before production commences, including the creation of production tools (such as photoplates and stencils), programming test equipment, and the time required for engineers to conduct data reviews and production line setups. These costs are fixed, regardless of whether you produce ten boards or ten thousand; the expense must be incurred. During the prototyping phase, this fixed cost is spread across a very small number of boards, resulting in a significantly high unit cost per board.

As order volumes increase, economies of scale become evident. Upon entering mass production, thousands of boards collectively share the same NRE costs, rendering each board’s cost contribution negligible. Furthermore, high-volume production yields additional cost advantages, such as bulk purchasing discounts for raw materials, enhanced automation efficiency on production lines, and reduced changeover and debugging time. Collectively, these factors drive a steep decline in unit costs as output increases.

How to Obtain Accurate Quotations and Select the Right Manufacturer?

Transitioning from theoretical understanding of cost structures to securing a genuine, precise quotation constitutes a pivotal step in the PCB procurement process. This endeavour demands meticulous preparation and systematic comparison to ensure you not only secure competitive pricing but also identify a reliable partner capable of fulfilling your technical and delivery requirements. Below is a practical step-by-step guide to efficiently navigate this process.

Step 1: Finalise and Verify Your Design Files Before contacting any manufacturer, the most crucial step is ensuring your design files are complete and error-free. The core files essential for manufacturer quotations and production are Gerber files, which detail the physical information of each PCB layer—copper traces, solder mask, silkscreen layers, etc. Additionally, you must prepare a Bill of Materials (BOM) listing all component types and quantities for placement, along with a drill file. The accuracy of these files directly impacts quotation precision and production efficiency.

Step 2: Define Your Manufacturing Specifications Prepare a clear specification list, closely tied to the cost-influencing factors discussed earlier. You must specify the following parameters:

PCB dimensions (length x width)

Required quantity (prototype or batch)

Number of layers

Board material type (e.g., FR-4)

Board thickness

Copper weight

Surface finish process

Solder mask and silkscreen colours

Desired delivery timeframe

Standardising this information ensures you receive quotes from different manufacturers based on identical criteria, enabling fair comparison.

Step 3: Conduct Initial Screening Using Online Comparison Tools For prototypes and small-batch orders, utilising online PCB circuit board price comparison websites proves highly efficient. Platforms such as PCB Shopper allow you to input uniform specification parameters and obtain instant quotes from over a dozen manufacturers simultaneously. This provides rapid market insight and filters out several competitively priced candidate suppliers, significantly saving time compared to individually visiting and completing quotation forms.

Step 4: Submit Detailed Requests for Quotation (RFQ) to Shortlisted Manufacturers

Following initial screening, select 2-3 most promising manufacturers and submit formal Requests for Quotation (RFQ) directly to them. Accompany these with your prepared Gerber files, Bill of Materials (BOM), and manufacturing specifications. At this stage, you may pose more detailed questions regarding their technical capabilities, quality certifications (e.g., ISO 9001), and any minimum order quantity requirements.

Step 5: Comprehensive Evaluation and Selection

Upon receiving quotations, avoid using price as the sole criterion. Conduct a holistic assessment across multiple dimensions:

Price: Compare total costs encompassing board charges, tooling fees, and shipping expenses.

Lead Time: Evaluate whether the manufacturer’s promised production and transit times align with your project schedule.

Technical Support: During communication, were their engineers responsive and professional? Robust technical support is crucial for resolving production issues.

Customer Reviews: Examine feedback from other clients to gauge reliability and service quality.

Understanding the core variables influencing PCB circuit board price enables you to avoid budget pitfalls and enhance product competitiveness through precise design. From prototyping to mass production, rational planning and transparent collaboration are key to balancing cost and quality.