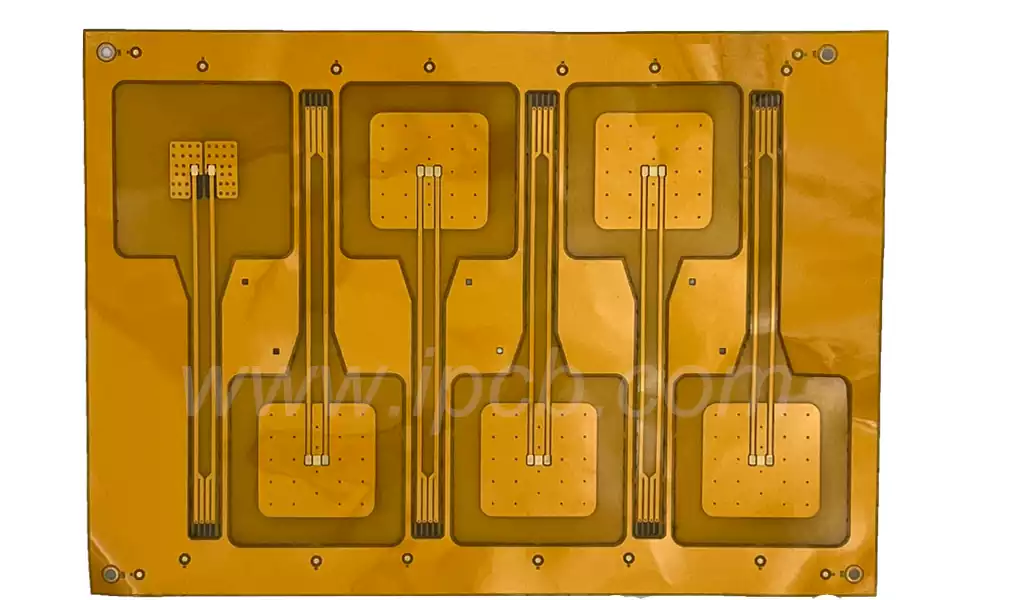

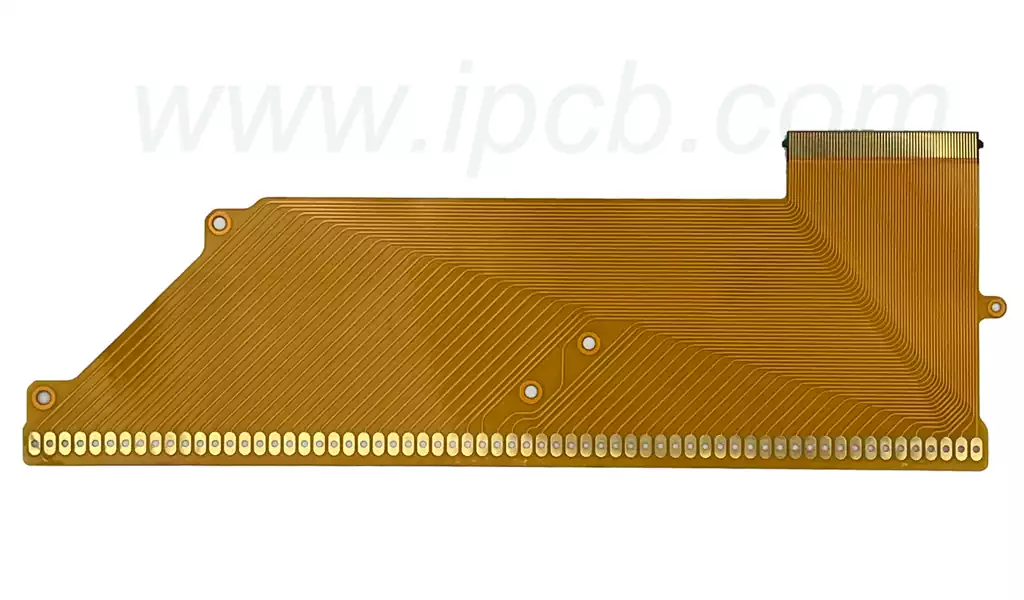

What is flex circuit? Flexible circuit boards, also known as flexible electronic circuits, are a kind of electronic components installed in the flexible plastic substrate (such as polyimide, polyether ether ketone, or transparent conductive polyester and other polymer materials) on the composition of the special circuit. It has the characteristics of being lightweight, thin thickness, soft bendable, etc. It shows high reliability and functionality in various applications.

Advantages

Flexible circuits offer many significant advantages over traditional rigid circuits. First, their bendable and curly characteristics make electronic products thinner, lighter, and more portable, providing designers with more room for creativity. Secondly, flexible circuits are characterized by high-density wiring, enabling electronic devices to achieve more complex functions and higher performance. In addition, flexible circuits also have the advantages of high reliability and low cost, making them an ideal alternative to rigid circuits in many fields.

Applications:

The flex board has a wide range of applications due to its unique advantages. In consumer electronic products such as cell phones and tablet PCs, the application of flexible circuits makes the devices thinner, lighter, and more beautiful. In the medical field, flex circuit can be used to manufacture wearable devices, implantable medical devices, etc., providing new means for disease prevention, diagnosis, and treatment. In addition, flexible circuits also have a wide range of application prospects in the automotive, aerospace, smart home, and other fields.

Classification:

Classification according to the number of layers: can be divided into four types: single panel, double-sided board, multilayer board, and just flexible circuit board.

According to the substrate classification: can be divided into adhesive flexible boards and non-adhesive flexible boards. Among them, the price of a non-glued flexible board is much higher than that flexible board with glue, but its flexibility, copper foil, substrate bonding, pad flatness, and other parameters are also better than the glued flexible board.

The through-hole with or without copper classification: can be divided into two types of copper through-hole and no copper through-hole.

According to the structure classification: can be divided into single-sided, double-sided, multi-layer flexible boards. Among them, multi-layer flexible board is made of multi-layer single-sided board or double-sided board bonding, which can increase the area of wiring.

According to the wiring density classification: can be divided into ordinary type and high-density type. High-density type flexible printed circuit boards have higher wiring density, which can meet the requirements of higher performance.

Manufacturing Processes

The manufacture of flexible pcb requires a series of advanced process technologies, including the preparation of flexible substrates, conductive material coating, graphic transfer, etching, and so on. Among them, the flexible substrate is the basis for manufacturing flexible circuits, usually using flexible materials such as polyimide and polyester. After preparing the substrate, a layer of conductive material is coated on the substrate through precision coating technology to form the circuit. Next, the conductive material is processed into the desired circuit pattern through the pattern transfer and etching process. Finally, a series of quality inspections and performance tests are performed to ensure the quality and reliability of the flexible circuits.

With the continuous development of technology, flex circuit will usher in more development opportunities in the future. First, with the rapid development of wearable devices, smart homes, and other fields, the demand for flexible circuits will continue to grow. Second, flexible circuit technology will continue to progress and is expected to achieve higher integration and smaller size, bringing more innovative applications for electronic products. In addition, with the improvement of environmental awareness, the green manufacturing technology of flexible circuits will also become the focus of research.