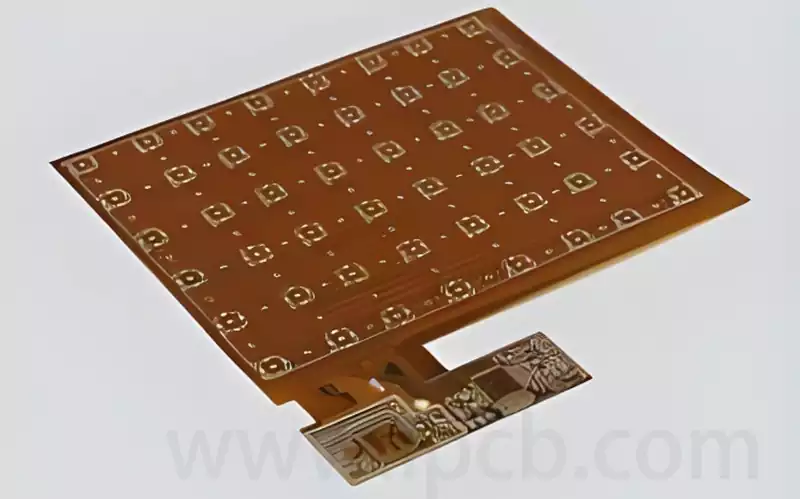

Among the numerous components of flexible circuits, flexible films serve as the core substrate, playing a decisive role in determining the performance of the entire circuit. Flexible circuits, also known as Flexible Printed Circuits (FPC), have emerged as a pivotal technology in meeting the evolving demands of electronic devices. This is due to their ability to realise complex circuit connections within confined spaces, coupled with their inherent properties of being bendable, foldable, and even twistable. Flexible films not only provide electrical insulation, mechanical support, and chemical protection for conductive traces and electronic components, but their inherent properties directly influence the circuit’s flexibility, foldability, electrical performance, and stability across diverse environments. As flexible circuit technology advances, increasingly stringent performance requirements for flexible films drive continuous innovation and breakthroughs in film technology, establishing it as a core driver of flexible circuit development.

Types and Characteristics of Flexible Films

Polyimide (PI) Film

Polyimide film stands as one of the most widely utilised flexible films in current circuit applications. It exhibits exceptional high-temperature resistance, maintaining long-term operational stability in elevated environments with a thermal decomposition temperature typically exceeding 500°C. Concurrently, PI film possesses high strength, high modulus, excellent chemical stability, and superior electrical insulation properties. Its inherent flexibility enables it to withstand repeated bending and folding without damage, providing reliable physical support for flexible circuits.

Polyester (PET) Film

Polyester film offers advantages such as lower cost, high transparency, and favourable mechanical properties. It is commonly employed in flexible circuits where high-temperature resistance requirements are relatively modest, but cost and optical performance remain significant considerations. PET film possesses high tensile strength, meeting certain mechanical strength requirements for flexible circuits, while its excellent insulation properties effectively prevent circuit short-circuiting.

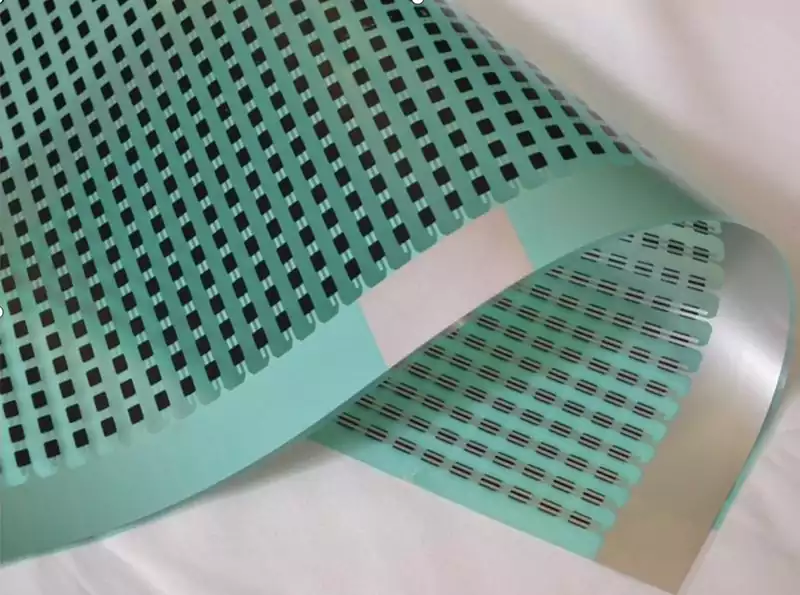

Other Novel Flexible Films

Beyond PI and PET films, several novel flexible films have emerged in recent years, such as liquid crystal polymer (LCP) film and polyethylene naphthalate (PEN) film. LCP film exhibits outstanding high-frequency performance, offering broad application prospects in high-frequency domains such as 5G communications. PEN film, meanwhile, demonstrates balanced thermal resistance, mechanical properties, and chemical stability, serving as a complementary alternative to PI film for flexible circuits with specific comprehensive performance requirements.

The Role of Flexible Films in Flexible Circuits

Electrical Insulation

As the substrate for flexible circuits, flexible films primarily serve an electrical insulation function. They effectively isolate different conductors within the circuit, preventing current leakage and short circuits to ensure normal circuit operation. For instance, PI film’s high insulation resistance and low dielectric constant reduce signal attenuation and interference during high-frequency, high-speed signal transmission, guaranteeing signal integrity.

Mechanical Support

Flexible circuits endure various external forces during use, including bending, folding, and stretching. Flexible films provide stable mechanical support for conductive traces and electronic components through their robust mechanical properties. Taking PI film as an example, its high strength and modulus ensure circuits maintain excellent electrical performance and physical structure after repeated bending, minimising issues like trace fractures or component detachment.

Chemical Protection

Flexible circuits may encounter diverse chemical substances in different operational environments, including moisture, acidic or alkaline solutions. Flexible films possess inherent chemical stability, shielding circuits from corrosion by such substances and prolonging the service life of the flexible circuit. For instance, PET film exhibits good resistance to common acidic and alkaline solutions, offering protection against chemical erosion.

Breakthroughs in Flexible Circuits: The Pivotal Role of Flexible Films

Optimisation and Upgrading of Manufacturing Processes

Innovations in High-Precision Printing Technology

Alongside the continuous refinement of flexible film performance, compatible manufacturing processes are advancing at a rapid pace. Advancements in high-precision printing technology have enabled the reproduction of increasingly intricate circuit patterns on flexible films. For instance, through the application of advanced photolithography and nanoimprinting techniques, conductor line widths can now be reduced to the micrometre or even nanometre scale, significantly enhancing the integration density and performance of flexible circuits. This achievement relies heavily on the robust support provided by the surface flatness and chemical stability of flexible films. Materials such as PI film maintain stable physical and chemical properties throughout complex lithography and imprinting processes, thereby ensuring the precise printing of high-precision circuit patterns.

Breakthroughs in Low-Temperature Processing

Traditional rigid circuit board manufacturing often relies on high-temperature environments, which can degrade the properties of flexible films. Recent years have witnessed remarkable developments in low-temperature processing techniques. Through the application of low-temperature curing conductive inks and low-temperature plasma treatment, flexible circuits can be manufactured without compromising the properties of the flexible film. For instance, certain novel low-temperature curing conductive inks solidify at temperatures below 100°C and exhibit excellent compatibility with flexible substrates like PI film. This not only renders the flexible circuit manufacturing process more energy-efficient and environmentally friendly but also broadens the application scope of flexible films across diverse manufacturing processes.

Significant Performance Enhancements

Enhanced Flexibility and Foldability

Advancements in flexible films have substantially improved the flexibility and foldability of flexible circuits. New flexible film materials maintain mechanical strength while further reducing material hardness and minimising bending radii. For instance, certain specially treated PI films achieve bending radii below 1mm, meeting the requirements for flexible circuits in foldable electronic devices. This enables more complex folding and bending configurations, opening new avenues for innovative electronic device design.

Optimised Electrical Performance

Flexible films have also delivered a qualitative leap in electrical performance for flexible circuits. With ongoing advancements in material technology, the dielectric constant and dielectric loss of flexible films continue to decrease. This enables flexible circuits to effectively reduce signal attenuation and delay during high-frequency signal transmission. For instance, LCP films, characterised by their extremely low dielectric constant and loss, facilitate high-speed, stable signal transmission in flexible circuits for 5G communications, meeting the stringent high-frequency performance requirements of 5G.

Flexible films serve as indispensable substrates for flexible printed circuits (FPCs), with their diverse types and properties directly determining the overall performance of FPCs. Whether it be the widely used polyimide (PI) films or the newer liquid crystal polymer (LCP) films, they provide critical electrical insulation, mechanical support, and chemical protection for flexible circuits.

Innovations in flexible films have not only advanced manufacturing processes such as high-precision printing and low-temperature processing but also significantly enhanced the flexibility, foldability, and electrical performance of flexible circuits. These breakthroughs enable flexible circuits to better meet modern electronic devices’ demands for slimness, bendability, and high performance.

Consequently, the ongoing development of flexible films remains the core driver of advancement in flexible circuit technology. With the continuous emergence of new materials and manufacturing processes, flexible films will continue to play a pivotal role in diverse innovative electronic products, propelling flexible circuits towards broader application prospects.