As the most widely used substrate in the PCB field, the flame retardancy of FR4 directly impacts the fire risk of end products. UL94-V0, the industry-recognised flame retardancy rating standard, serves as the ‘safety pass’ for FR4 board. Understanding the UL94-V0 standard for FR4 laminate enables precise control of safety thresholds in product design, preventing hidden hazards caused by substandard substrate flame retardancy.

What is UL94-V0?

UL94 is a plastic material flame retardancy testing standard established by Underwriters Laboratories (UL), serving as the most widely adopted basis for determining flame retardancy grades within the global electronics industry. This standard categorises plastic materials into multiple flame-retardant grades through various testing methods, including vertical and horizontal burning. Among these, the vertical burning test grades (V0, V1, V2) constitute the most critical flame-retardant evaluation metric for FR4 laminates. V0 represents one of the highest grades within this system, signifying the material possesses outstanding flame-retardant properties.

For FR4 laminates, the core definition of UL94-V0 is: under specified vertical burning conditions, the material rapidly self-extinguishes without sustaining combustion, and produces no burning droplets capable of igniting combustible materials below. This seemingly straightforward definition encompasses three critical safety dimensions: self-extinguishing speed (preventing fire spread), absence of sustained combustion (controlling burn area), and non-ignitable dripping (avoiding secondary fires). Compared to the lower V1 and V2 grades, V0 imposes stricter requirements on burn duration and dripping behaviour, making it the core material selection criterion for high-safety-grade electronic equipment.

It must be clarified that UL94-V0 does not denote ‘non-combustibility’ but rather ‘controlled combustion’. Any material may burn under extreme temperatures; the core value of flame retardancy lies in ‘preventing fire propagation’, buying time for electronic equipment fault alerts and personnel evacuation. FR4 laminates achieving UL94-V0 signify their ability to effectively suppress fire spread during initial stages, thereby mitigating accident severity.

Test Procedure and Evaluation Criteria for UL94-V0 Standard

1.Test Sample Preparation

Test samples shall be cut from FR4 sheet material, strictly adhering to UL94 specifications: sample length 127mm, width 12.7mm, with thickness corresponding to commonly used practical applications (typically 1.6mm, though 0.8mm, 2.0mm, etc. may be tested per client requirements). Five identical specimens must be prepared per batch, with surfaces free from oil contamination and damage to ensure test accuracy. Prior to testing, specimens shall be conditioned for 48 hours at 23°C and 50% relative humidity to simulate typical operational environments.

2.Test Environment and Equipment

Tests shall be conducted within a dedicated vertical burning test chamber equipped with precise flame height and duration control functions. The combustion source shall be a methane burner, with the flame height adjusted to 20mm and the flame temperature maintained at 950°C (precisely measured via thermocouple). During testing, the sample shall be vertically secured, with the burner flame applied at a 45° angle from the lower edge of the sample to ensure uniform flame envelopment of the sample’s base. A layer of dry, degreased cotton wool shall be positioned 300mm below the sample to detect whether combustion droplets exhibit ignitability.

3.Core Test Procedure

The core assessment for UL94-V0 is the ‘two-ignition’ test, conducted as follows: First ignition: Apply the torch flame to the sample’s lower edge for 10 seconds before removal. Record the sample’s burning time (self-extinguishing time). If the sample extinguishes after flame removal, allow it to cool to ambient temperature (approximately 60 seconds) before performing a second ignition. Again, apply the flame for 10 seconds before removal and record the self-extinguishing time. Throughout the entire test, continuously observe the sample’s combustion state, whether any dripping occurs, and whether such dripping ignites the underlying absorbent cotton.

4.Assessment Criteria

To achieve UL94-V0 rating, FR4 laminates must concurrently satisfy all three mandatory criteria: ① Self-extinguishing time after both ignitions ≤ 10 seconds, with total self-extinguishing time for 5 samples ≤ 50 seconds; ② No sustained combustion during testing (i.e., sample must not burn continuously for over 10 seconds after flame removal); ③ No flaming droplets shall be produced during combustion, or any droplets produced shall be non-ignitable (i.e., the absorbent cotton below shall not ignite). Should any single sample fail to meet any one of these criteria, the entire batch of FR4 laminate shall be deemed ineligible for UL94-V0 certification.

Comparing this to other vertical burning ratings (V1, V2) highlights the stringent nature of V0: the V1 rating requires both self-extinguishing times ≤30 seconds, with a total self-extinguishing time ≤250 seconds; the V2 rating has identical self-extinguishing time requirements to V1 but permits burning droplets to ignite the cotton wool. This demonstrates that UL94-V0 imposes significantly higher demands than lower grades regarding self-extinguishing speed and secondary fire prevention.

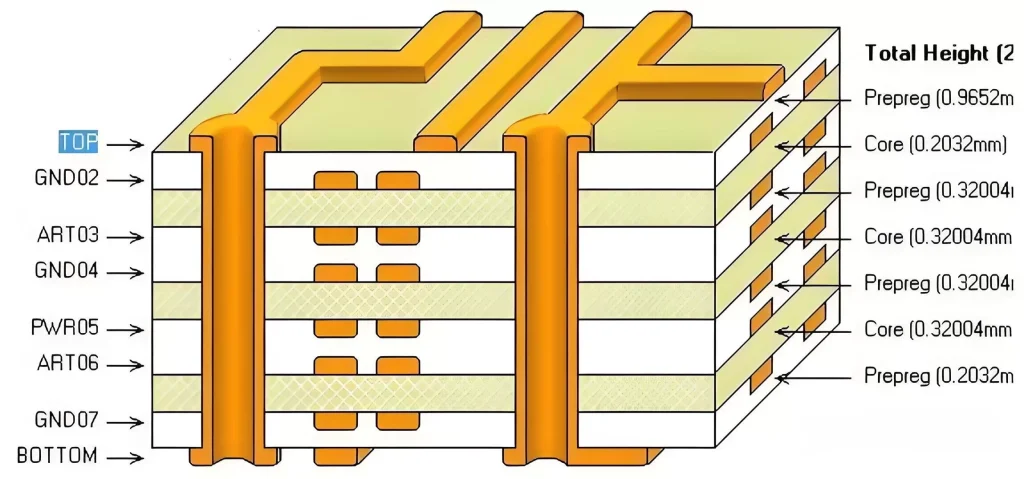

Conventional FR4 laminates primarily consist of epoxy resin, glass fibre cloth and copper foil. The epoxy resin itself possesses inherent flammability and cannot directly achieve UL94-V0 rating. To impart superior flame retardancy to FR4, the core approach involves optimising the base material formulation through ‘flame retardant modification’. This leverages the action of flame retardants to interrupt combustion reactions, enabling rapid self-extinguishing.

1.Core Function of Flame Retardants

Flame retardants incorporated into FR4 sheets operate through three primary mechanisms, forming a three-tier defence against combustion: ① Heat absorption and cooling: At elevated temperatures, flame retardants undergo phase transitions such as decomposition and melting, absorbing substantial heat and reducing the substrate’s temperature, thereby inhibiting sustained combustion; ② Formation of a Char Layer: Certain flame retardants (e.g., brominated and phosphorus-based compounds) induce the epoxy resin to form a dense char layer at elevated temperatures. This layer coats the substrate surface, isolating oxygen from combustible materials and interrupting the chain reaction of combustion; ③ Release of inert gases: During decomposition, flame retardants emit inert gases such as nitrogen and carbon dioxide, diluting oxygen concentrations in the combustion zone and inhibiting fire spread.

2.Mainstream Flame Retardant Technology Pathways

Current flame retardant technologies enabling FR4 laminates to achieve UL94-V0 rating primarily follow two pathways: brominated flame retardants and halogen-free flame retardants. These exhibit significant differences in flame retardancy efficacy, environmental impact, and performance effects.

Brominated flame retardancy represents the traditional mainstream approach, achieved by incorporating brominated epoxy resins, tetrabromobisphenol A, and similar brominated flame retardants into epoxy resins. Brominated flame retardants offer high efficiency, requiring only a small addition (typically 10%-15%) to achieve UL94-V0 rating for FR4. They are cost-effective and exert minimal impact on FR4’s dielectric properties and mechanical strength. However, brominated flame retardants release toxic and harmful gases (such as hydrogen bromide) during combustion and fail to meet environmental standards like RoHS. Consequently, their use is increasingly restricted in sectors with stringent environmental requirements, such as consumer electronics and medical equipment.

Halogen-free flame retardant technology represents a recent developmental trend, primarily employing phosphorus-, nitrogen-, and silicon-based halogen-free flame retardants. These enhance flame retardancy through a ‘phosphorus-nitrogen synergistic flame retardation’ mechanism. Halogen-free flame retardants do not release toxic or harmful gases during combustion, comply with environmental standards such as RoHS and REACH, and are suitable for high-end consumer electronics, automotive electronics, and medical equipment sectors. However, halogen-free flame retardants exhibit relatively lower efficiency, necessitating higher dosages (typically 20%-30%) to achieve UL94-V0 rating. This leads to a slight increase in FR4 dielectric loss (Df) and a marginal reduction in impact resistance. To address this, the industry has optimised flame retardant formulations (e.g., employing nano-scale halogen-free compounds) and refined epoxy resin synthesis processes. This enhances flame retardancy while minimising adverse effects on other FR4 properties.

3.Impact of Production Processes on Flame Retardancy

Beyond formulation optimisation, production process control directly influences the stability of FR4 laminate flame retardancy. Laminating is critical: insufficient temperature or pressure results in poor bonding between epoxy resin, flame retardants, and glass fibre cloth, causing uneven distribution and potential localised flame retardancy deficiencies. Conversely, excessively high temperatures or prolonged lamination times may cause premature decomposition of flame retardants, nullifying their effectiveness. Consequently, achieving UL94-V0-rated FR4 laminates necessitates strict control of lamination parameters (temperature: 170–180°C; pressure: 30–40 MPa; time: 60–90 minutes) to ensure uniform flame retardant distribution and a dense substrate structure.

Impact of UL94-V0 Rating on FR4 Sheet Applications

1.Consumer Electronics Sector

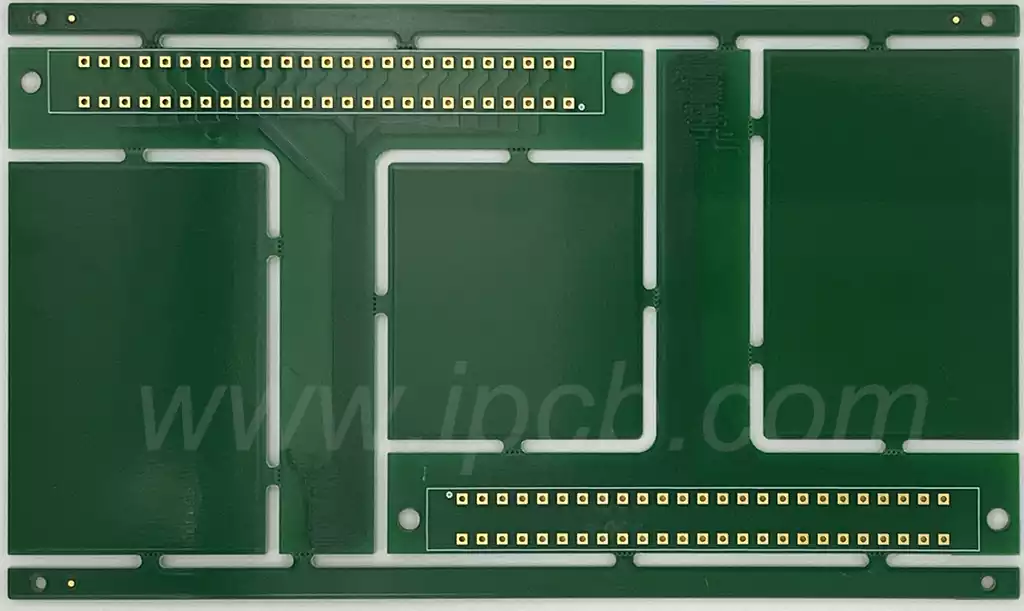

Consumer electronic devices such as mobile phones, computers, routers, and smart televisions feature compact internal spaces with densely packed electronic components. Short-circuit faults can readily generate high temperatures, potentially triggering fires. Consequently, PCB substrates for such equipment universally require UL94-V0 rating compliance. Concurrently, heightened environmental awareness has driven the adoption of halogen-free, flame-retardant UL94-V0 FR4 laminates in consumer electronics. This approach satisfies both flame-retardant safety requirements and environmental standards such as RoHS. For instance, the mainboard PCBs in smartphones and the power management PCBs in laptops utilise halogen-free, flame-retardant UL94-V0 FR4 laminates to ensure operational safety.

2.Industrial Control and Automotive Electronics Sectors

Industrial control equipment (such as inverters, PLCs, and industrial gateways) typically operates in harsh environments characterised by high temperatures and dust accumulation, presenting elevated fire risks. Automotive electronics (including in-vehicle navigation systems and power battery management systems) must withstand extreme conditions like high temperatures and vibration, demanding even more stringent flame-retardant properties. FR4 laminates for these sectors must not only achieve UL94-V0 rating but also exhibit superior high-temperature resistance (high Tg). For instance, PCBs in automotive battery management systems utilise high-Tg, halogen-free, UL94-V0 FR4 laminates that maintain structural integrity under elevated temperatures while effectively suppressing combustion during malfunctions.

3.Medical Equipment and Aerospace Applications

Medical devices (such as ventilators, patient monitors, and surgical instruments) directly impact patient safety, demanding the highest standards of flame retardancy. Aerospace equipment (including satellite electronics and aircraft cockpit systems) operates in specialised environments where fire incidents could have catastrophic consequences. FR4 laminates in these sectors must not only achieve UL94-V0 classification but also pass stricter flame retardancy tests (e.g., smoke density and toxic gas emission tests). For instance, PCBs in medical ventilators utilise high-purity, halogen-free UL94-V0 FR4 laminates to ensure prolonged operation without safety hazards.

4.Low-end electronics sector

In certain low-end electronic devices (such as standard remote controls or small toy electronic components), where power consumption is low and operating environments are straightforward, fire risks are relatively minimal. To control costs, manufacturers may opt for UL94-V1 or V2 rated FR4 boards, or even standard FR4 boards without flame retardant ratings. However, market access standards for such devices are comparatively low, and explicit safety warnings must be included in product manuals.

Key Considerations for UL94-V0 Grade FR4 Sheets

Choosing Brominated vs Halogen-Free Flame Retardants

For applications in environmentally stringent sectors such as consumer electronics, medical devices, or automotive electronics, halogen-free UL94-V0 FR4 laminates must be selected, with suppliers required to provide environmental compliance reports (e.g., RoHS, REACH). For low-end industrial equipment with minimal environmental requirements, brominated UL94-V0 FR4 laminates may be chosen to balance cost and flame retardancy.

Balancing Flame Retardancy with Other Properties

Halogen-free UL94-V0 FR4 laminates may exhibit slightly inferior dielectric loss and impact resistance compared to brominated variants. For high-frequency applications (e.g., WiFi, 5G terminals), low-loss halogen-free UL94-V0 FR4 laminates must be selected to ensure dielectric properties meet signal transmission requirements. For applications involving severe vibration (e.g., automotive electronics), high-toughness UL94-V0 FR4 laminates should be selected to enhance mechanical strength.

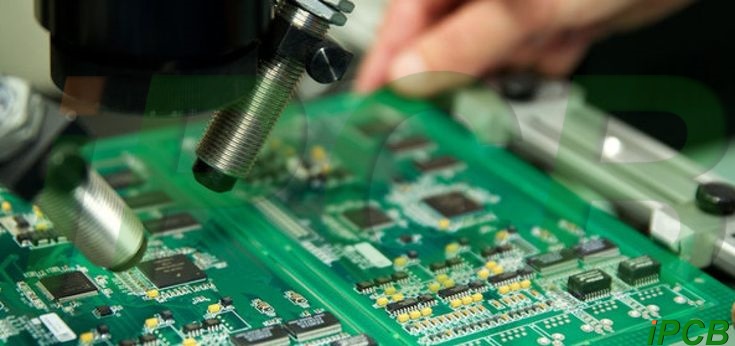

Verifying Certification Credentials

Certain ‘pseudo-compliant’ UL94-V0 FR4 laminates exist on the market. These products have not undergone formal UL certification but claim V0 rating after superficial testing, posing significant safety risks. Therefore, during selection, suppliers must be required to provide formal UL certification documents (certificate numbers verifiable on the UL official website), and conduct sampling retests of flame-retardant properties to ensure compliance with standards.

Consideration of Special Application Environments

For use in extreme conditions involving high temperatures, high humidity, or multiple chemical corrosions, select UL94-V0 FR4 laminates with superior environmental resistance (e.g., high Tg, moisture-resistant FR4) to prevent degradation of flame-retardant properties due to environmental factors. For instance, electronic equipment near high-temperature industrial furnaces requires UL94-V0 FR4 laminates with a Tg ≥ 170°C.

UL94-V0 rating is not an ‘additional attribute’ of FR4 laminates, but rather the fundamental threshold for high-safety-standard electronic equipment. Through rigorous testing protocols, it defines the safety performance of FR4 laminates in fire risk scenarios, providing core assurance for the safety performance of end products. Looking ahead, as environmental requirements intensify and flame-retardant technologies advance, halogen-free, low-loss, and highly stable UL94-V0 FR4 laminates will become the industry standard. This shift will provide stronger support for the electronics sector’s transition towards safer and greener development.