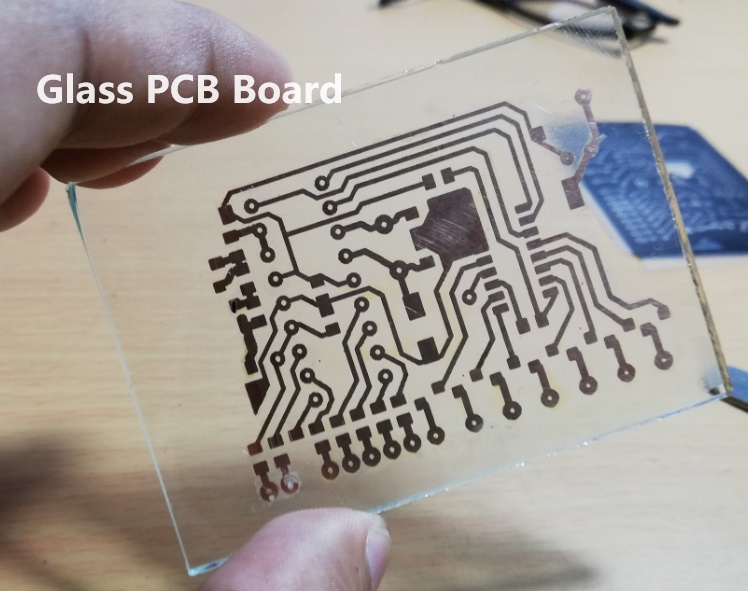

Glass PCB board is a new type of circuit board material, mainly using a mixture of glass fiber and epoxy resin, with high strength, high temperature resistance, flame retardant and other excellent characteristics. Compared with traditional FR-4 material PCB, glass PCB board has better performance and is widely used in high-end electronic products, such as aerospace, rail transportation, military equipment and other fields.

Features of glass PCB board:

- High flatness and low roughness: Glass PCB board has extremely high surface flatness and low roughness, which provides an ideal platform for the manufacturing of micro-sized semiconductor devices.

- Thermal Stability and Low Coefficient of Thermal Expansion: Glass PCB boards are thermally stable and can maintain stable performance in high temperature environments, and their coefficients of thermal expansion are close to those of silicon, which helps to minimize stress problems caused by thermal mismatches during the packaging process.

- High dielectric constant and low dielectric loss: part of the glass material has a high dielectric constant, which helps to reduce the size of passive components, improve integration. At the same time, its low dielectric loss is conducive to high-speed signal transmission and reduce energy consumption.

- Chemical stability and corrosion resistance: glass PCB board chemical stability is excellent, can effectively resist moisture, acid and alkali and other environmental erosion, to protect the long-term stability of the components in the package.

- High transparency and optical properties: For packaging applications that require transparent windows or involve optical communication, glass PCB boards have unique advantages in terms of high transparency and excellent optical properties (such as adjustable refractive index).

- Environmental protection and long-term reliability: Glass PCB boards are usually free of organic volatiles, making them more environmentally friendly. Its stable physical and chemical properties give the packaging products excellent long-term reliability.

Of course, glass PCB boards do not have all the advantages. When manufacturing, it is also necessary to consider fragility, lack of adhesion to metal wires, and the difficulty of achieving uniform through-hole filling, which is also very critical to the electrical performance. Additionally, glass, with its high transparency and varying reflection coefficients, can also present inspection and measurement difficulties for the chip industry. Measurement techniques now used for opaque or semi-transparent materials are less effective on glass and can lead to distortion or loss of signal, affecting measurement accuracy and ultimately leading to a decline in chip yields.

Application areas of glass PCB board:

- Automotive industry: In the automotive industry, electronic devices often need to withstand high operating temperatures and require electronic components with a long service life. Glass PCB boards are particularly suitable for high-performance electronic systems in automobiles.

- Aerospace: Aerospace field for the reliability and durability of electronic equipment requires high, glass PCB board can withstand extreme environmental changes, including temperature fluctuations and vibration.

- LED Lighting: In LED lighting applications, glass PCB boards can provide better thermal management to help LED lamps and lanterns maintain luminous efficacy and extend service life.

- Medical Electronics: Durability and bio-inertness allow for use in implantable devices.

- Solar Power Devices and Systems: Solar power devices, such as photovoltaic inverters, and solar cells, require PCBs to dissipate heat efficiently. Otherwise, the accumulated heat affects the chip and reduces the efficiency of photovoltaic conversion, and the life of the electronic components is shortened. Glass PCB boards can quickly transfer heat away from the chip. And they have a small coefficient of thermal expansion. In addition, since glass replaces expensive semiconductors, manufacturing costs will be reduced.

- New energy electrical and electronic devices and systems: The thermal management system of new energy electrical equipment and devices mainly includes batteries, power components, motors, air conditioners and so on. The increase in power leads to higher heat dissipation requirements for circuit boards, and glass PCBs can handle the heat dissipation needs.

In the continuous evolution of technology, glass PCB board technology is facing unprecedented challenges and opportunities. From the limitations of mechanical properties to the test of impact resistance, every technological breakthrough is a profound tribute to human wisdom. And with the development of advanced packaging technology and the unremitting efforts of domestic and foreign enterprises, we have reason to believe that the glass PCB board will open up a broader world of application with its more excellent performance.