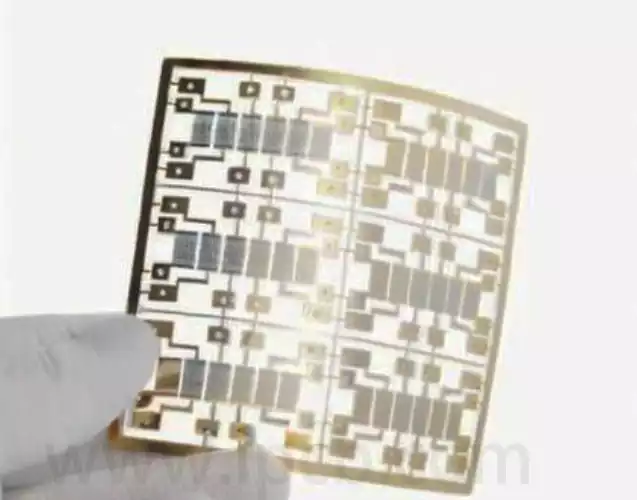

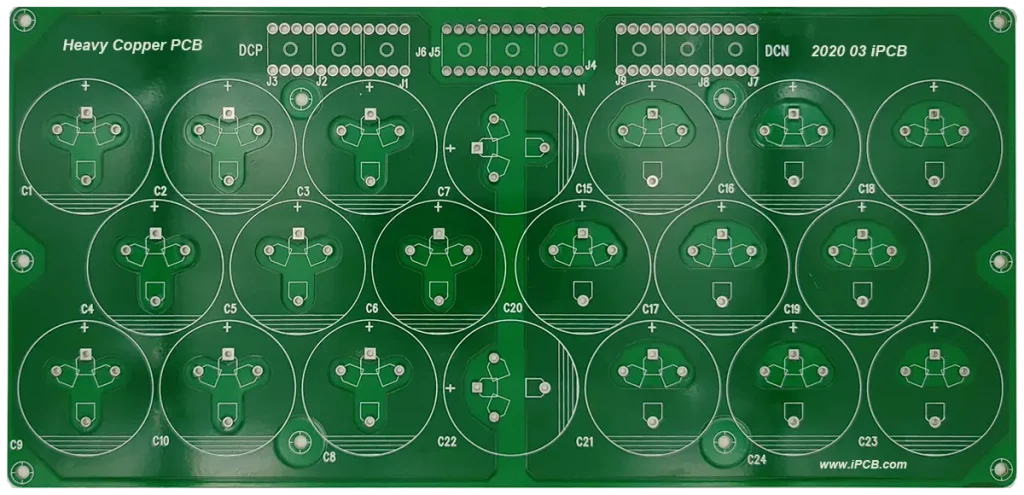

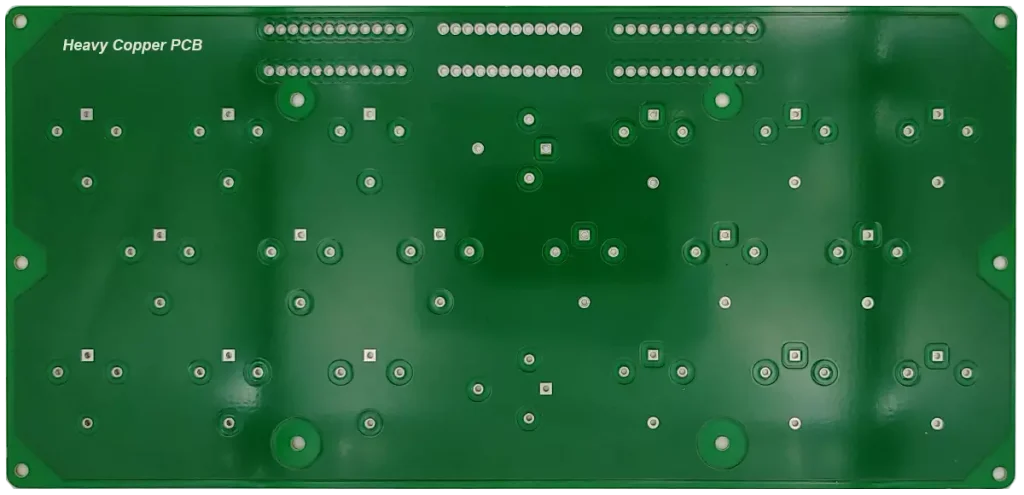

Heavy Copper PCB is a special type of printed circuit board with a copper foil thickness much greater than that of conventional circuit boards. These boards are specially treated during the manufacturing process and are characterized by high electrical conductivity, high thermal conductivity and high stability, and therefore excel in high-current and high-frequency application scenarios.

Features and Advantages of Heavy Copper PCB

High conductivity: The copper foil is thicker and therefore has excellent conductivity. When transmitting large currents, it is not easy to generate an overheating phenomenon, to ensure the stability and safety of current transmission.

High thermal conductivity: copper foil is thicker and its thermal conductivity is relatively high. This helps to improve the heat dissipation of electronic equipment and reduces the risk of malfunction due to overheating.

High stability: Copper foil is thicker and less susceptible to external environmental influences such as temperature and humidity. Therefore, it has high stability and can maintain excellent performance for a long time.

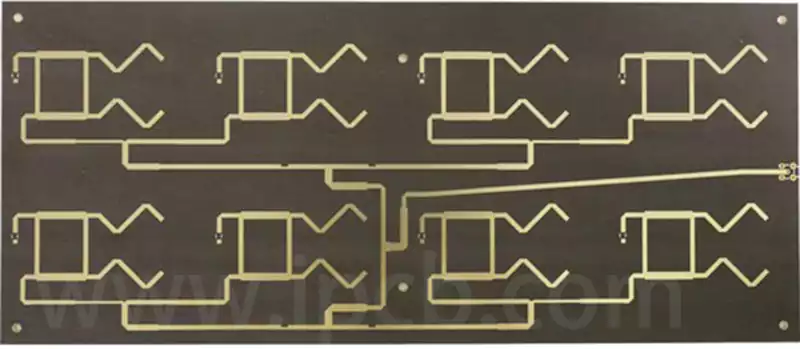

Suitable for high-current and high-frequency applications: High electrical conductivity and high thermal conductivity make it particularly suitable for high-current and high-frequency application scenarios. Heavy Copper PCB play a crucial role in power electronics, high-speed digital signal processing, and other fields.

Application Scenarios for Heavy Copper PCB

Power Electronics: In the field of power electronics, Heavy Copper PCB are widely used for their ability to withstand high currents and high-frequency signal transmission. For example, power supplies, converters, and other critical equipment cannot do without the support. It provides these devices with efficient and stable power transmission to ensure the normal operation of the equipment.

High-speed digital signal processing: In the field of high-speed digital signal processing, the data transmission speed is extremely high. The high electrical conductivity and high thermal conductivity of Heavy Copper PCB help to realize high-speed and efficient signal transmission and processing. It provides a stable and reliable high-speed signal transmission channel for computers, communication equipment, etc., and meets the stringent requirements of modern digital technology.

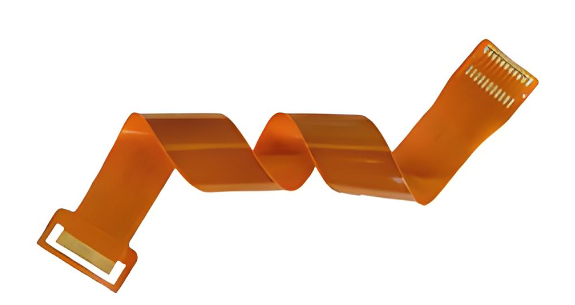

Communication equipment: Communication equipment needs to transmit a large amount of data and signals, which requires extremely high quality and stability of signal transmission. Its high conductivity and stability can meet this demand, providing strong support for the normal operation of communication equipment.

Automotive electronics: In the field of automotive electronics, stability and safety are of paramount importance. High stability, high conductivity, and high thermal conductivity help to improve the safety and reliability of automobiles. It is widely used in automotive engine control, safety systems, and other key parts of the car, for the safe driving of the car to provide a strong guarantee.

Aerospace: In the aerospace field, the safety and reliability of electronic equipment require a high degree of reliability. High performance and stability are indispensable and are widely used in the electronic equipment of various aircraft and spacecraft. For example, aircraft and satellite control systems, navigation systems, etc. are inseparable from the support of Heavy Copper PCB.

As a high-performance printed circuit board, Heavy Copper PCB is becoming more and more widely used in various fields due to its unique features and advantages. Whether it is power electronics, high-speed digital signal processing, communications equipment automotive electronics aerospace and other fields, all play an important role. With the continuous development of science and technology, the application of Heavy Copper PCB will be more broad prospects, and become an important force to promote the technological progress of various industries.