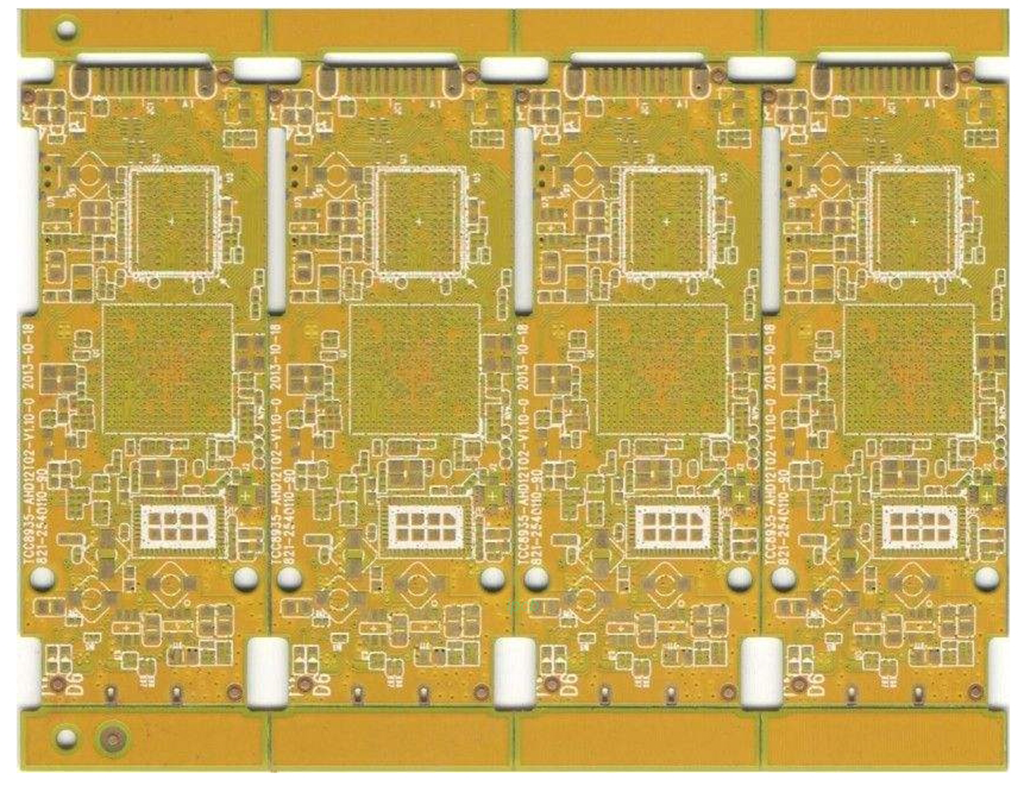

Hybrid PCB is integrated circuit made by the combination of a semiconductor integration process and thin (thick) film process, is a film on the substrate with a film-forming method to produce thick or thin film components and their interconnections, and discrete semiconductor chips, monolithic integrated circuits or micro-components on the same substrate, mixed assembly, and then external encapsulation and become. Compared with discrete component circuits, hybrid PCB is characterized by high assembly density, high reliability, and good electrical performance. Relative to monolithic integrated circuits, it is designed to be a flexible, convenient process, to facilitate the production of small batches of multiple varieties; and components of a wide range of parameters, high precision, good stability, and can withstand higher voltages and greater power.

Hybrid circuit board material characteristics mainly include the insulation and mechanical strength of the substrate materials, conductor materials, electrical conductivity and processing performance, adhesive materials, adhesive properties, and electrical properties, insulating materials, insulating properties and heat resistance, as well as encapsulation materials, mechanical strength, heat resistance, and electrical properties. The selection and application of these material properties directly affect the performance and reliability of the hybrid pcb:

Substrate materials: commonly used substrate materials for hybrid circuit boards include thick film, thin film, and so on. These materials have high insulating properties and heat resistance to meet the requirements of circuit board manufacturing. In addition, the substrate materials also need to have a certain degree of mechanical strength and processing performance to ensure the stability and reliability of the circuit board.

Conductor materials: hybrid circuit boards in the conductor material usually use copper, aluminum, or its alloys. These materials have excellent conductive properties and processing performance and can meet the circuit board conductive requirements. In the manufacturing process, the conductor material can be printed, sputtered, vaporized, and other means of deposition on the substrate, the formation of circuit graphics.

Adhesive materials: The individual components and circuit graphics in a hybrid circuit board need to be bonded with adhesives. Commonly used adhesive materials include epoxy resin, polyimide, etc… These materials have excellent adhesive properties, heat resistance, and electrical properties to ensure the stability and reliability of the PCB board.

Insulating materials: The insulating materials in hybrid circuit boards are usually ceramics, glass, polyimide, and so on. These materials have high insulating and heat-resistant properties, which can ensure the electrical performance and reliability of the circuit board. Insulation materials can be used to manufacture passive components, insulation isolation, etc…

Encapsulation materials: Components and circuit graphics in hybrid circuit boards need to be protected and encapsulated to achieve their function and reliability. Commonly used encapsulation materials include metals, ceramics, and plastics. These materials have high mechanical strength, heat resistance and electrical properties to ensure the stability and reliability of the circuit board.

As an electronic component that integrates a variety of functions and technologies, hybrid circuit boards are used in a wide range of application scenarios, with the following obvious advantages.

High integration: able to integrate multiple chips and components on a single printed circuit board to achieve multi-functionality and miniaturization needs.

Miniaturization: To achieve a smaller size and lighter weight, making electronic products more portable and lightweight.

High Reliability: The high degree of integration of hybrid circuit boards reduces the number of connectors and connectors, reduces the failure rate, and improves the reliability of the system.

High performance: The use of advanced microelectronics technology and high-density integration makes electronic products have higher performance and efficiency.

Customization: They can be tailored to meet specific application requirements, enabling individualized functionality and design.

Cost-effective: Although hybrid circuit boards are more expensive to manufacture, their ability to achieve high levels of integration and miniaturization reduces the use of other components and materials, thereby lowering overall costs.

Application Scenario:

Communication equipment: It can be used to manufacture key components in communication equipment such as cell phones, routers, base stations, etc., to realize functions such as signal transmission, processing, and conversion.

Medical equipment: integration and miniaturization characteristics, it is also widely used in medical equipment, such as pacemakers, blood pressure monitors, blood glucose meters, and so on.

Aerospace: Application scenarios in the aerospace field include flight control systems, satellite communication systems, etc.

Industrial Control: In the field of industrial control, it can be used in a variety of automation equipment and control systems to improve productivity and equipment performance.

Consumer Electronics: Widely used in consumer electronics products, such as tablet PCs, digital cameras, smart watches, etc.

iPCB is a PCB manufacturing factory, that provides a variety of well-known brands of hybrid circuit pcb and has prepared sufficient PCB boards to meet your rapid needs.