The air conditioner circuit board is the control center of the air conditioning system and is responsible for collecting signals from the remote control or sensors and issuing commands based on these signals in order to regulate and control the operating status of other components such as the compressor and fan. Through effective signal processing, the circuit board enables the air conditioner to provide the desired level of comfort in different environmental conditions.

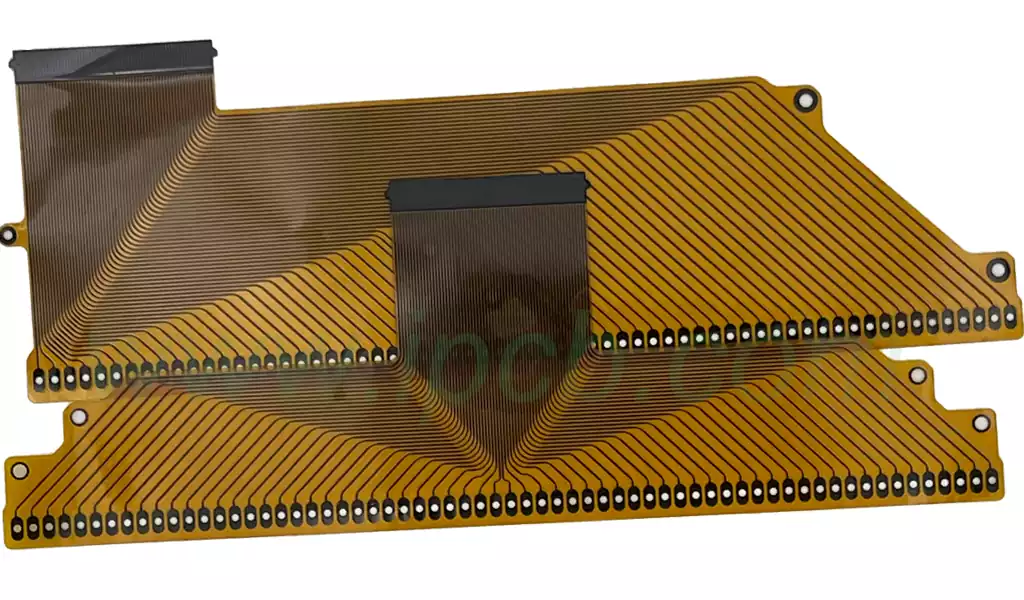

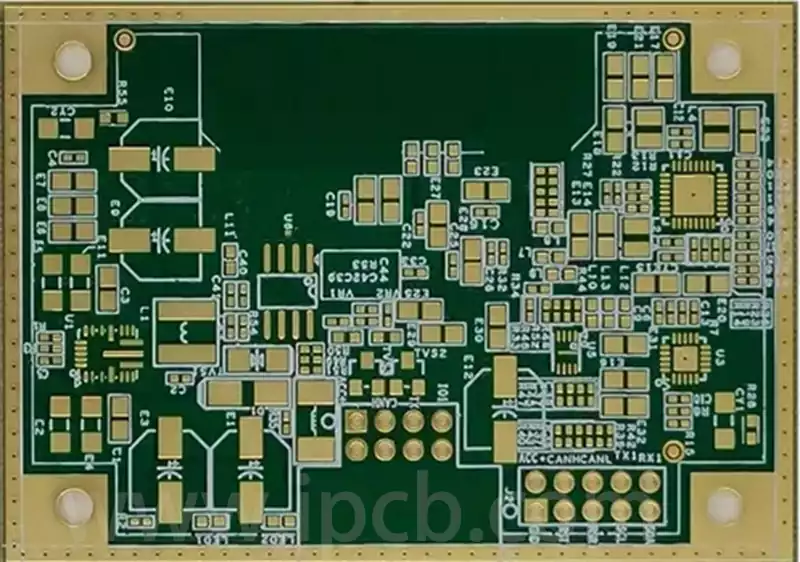

An air conditioning circuit board typically consists of a variety of components, including integrated circuit chips, sensors, connectors, and power modules. Integrated circuit chips are used to process signals and control logic, while sensors are used to sense changes in the space such as temperature and humidity. The connection of these components is achieved through connectors with multi-core wires, ensuring that the various parts of the system can communicate smoothly.

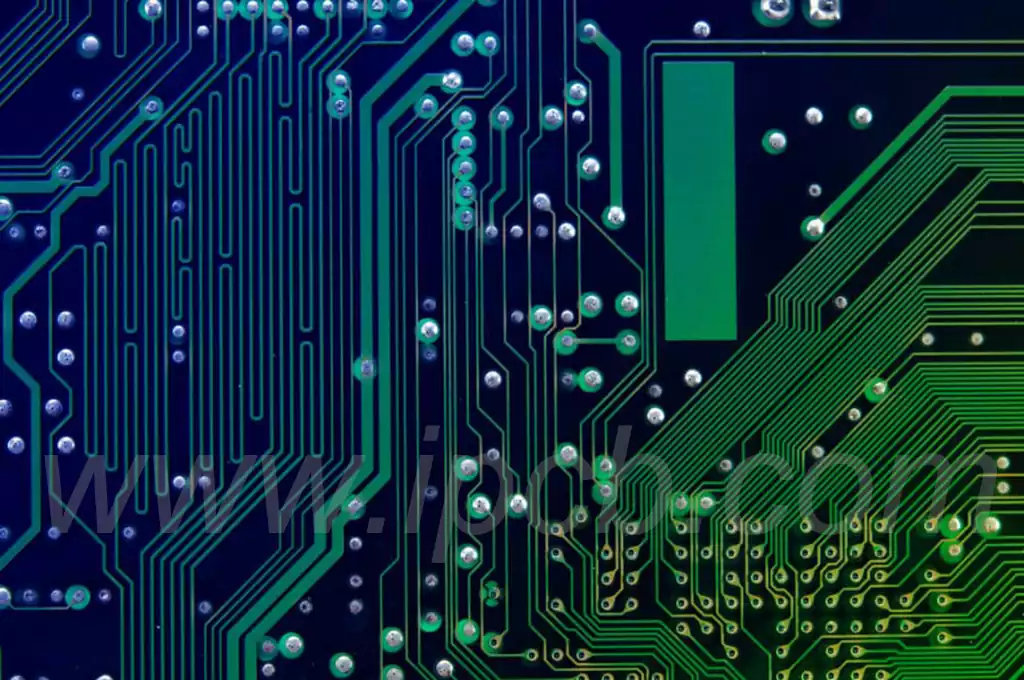

Air conditioner circuit boards work based on feedback from temperature sensors. When the ambient temperature or the temperature of an equipment component (e.g., the evaporator) changes, the temperature sensor converts these changes into electrical signals that are sent to the CPU for calculation, which then operates the air conditioner according to the set control logic.

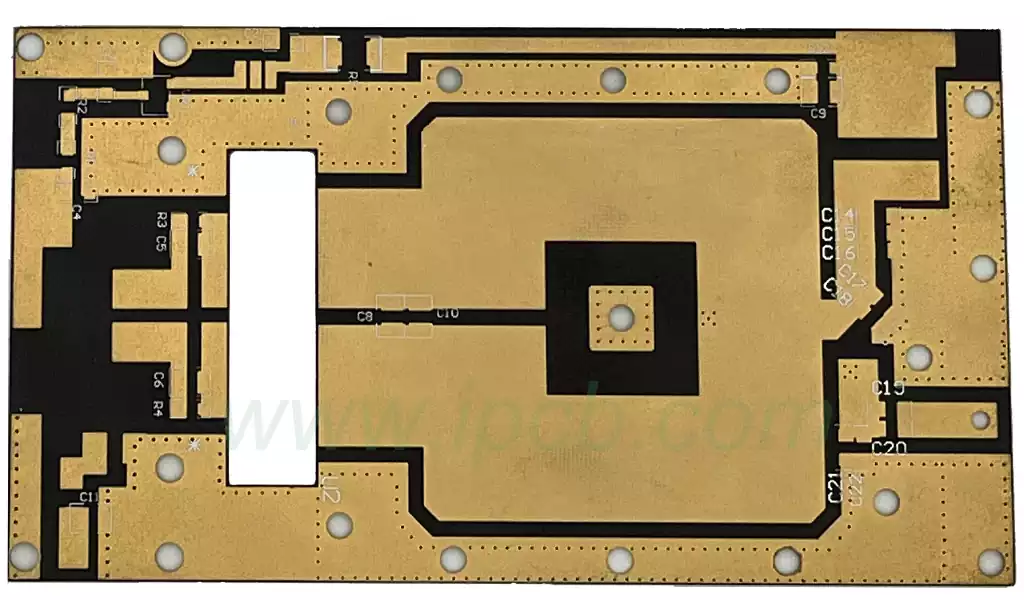

The main materials used in air conditioning circuit boards include flame-retardant polycarbonate (PC) and FR-4. PC is a commonly used plastic with excellent impact resistance and transparency, and is more suitable for use in circuit boards that require good mechanical properties, while FR-4 is a composite of epoxy resins and glass fibers that is widely used in various types of electronic products, and has good electrical insulation and heat resistance.

The glass transition temperature (Tg) is an important parameter in air-conditioned circuit boards. Materials with high Tg values are able to maintain their electrical properties at high temperatures, preventing the board from degradation caused by temperature changes. For example, the best choice is a material with a Tg value of 170°C or higher, which effectively improves the board’s durability.

Materials used in air-conditioning circuit boards need to have good heat resistance and protective properties against high temperatures and humid environments. Flame retardant materials can extinguish themselves at high temperatures to prevent the risk of fire, so they are widely used in circuit boards. In addition, triple-proof coating materials, such as silicone materials, provide additional protection against water, dust and corrosion.

In addition to electrical and thermal properties, the mechanical strength and impact resistance of air conditioning circuit board materials should not be overlooked. Air conditioning equipment often needs to operate in different environments, so the durability of the material will directly affect the service life of the circuit board. High-strength materials, such as polycarbonate and treated FR-4, provide good mechanical stability, ensuring the reliability and durability of the circuit board in a wide range of operating conditions.

Air conditioner circuit boards may experience a variety of faults during operation,such as power failures,short circuits,and component damage.These malfunctions usually result in the air conditioner not working properly, affecting the user’s comfort experience. Common causes of malfunctions include aging components, failure of solder joints, and high ambient humidity. In the event of a malfunction, users are advised to immediately disconnect the power and consult a professional technician to avoid wider damage.

Common steps when repairing an air conditioner circuit board include:

Troubleshooting: determine the point of failure by measuring voltage and current.

Checking connections: ensuring that all connectors are tight and not oxidized.

Replacement of components: Replacement for damaged components, ensuring that qualified parts are used.

Soldering Repair: If the soldering point is found to be problematic,it should be re-soldered to improve the contact effect.

Function test: After completing the repair, carry out system test to ensure that all functions are normal.

With the continuous progress of technology, the air conditioning circuit board is also evolving. In recent years, the application of intelligent and Internet of Things (IoT) technologies has equipped air conditioning circuit boards with more advanced functions, such as remote control, data analysis and self-learning capabilities. These new technologies enable air conditioning systems to not only achieve basic temperature regulation, but also more personalized adjustments based on the user’s habits and environmental conditions.

Intelligent control: Controlling the air conditioner’s on/off, temperature settings and operating modes through mobile applications greatly improves the user experience.

Data analysis: By monitoring and analyzing usage data, the air conditioner is able to self-optimize, improve energy efficiency and extend equipment life.

Environmental adaptability: New sensor technology enables air conditioners to sense changes in the indoor and outdoor environments in real time, automatically adjusting the operating state to achieve optimal comfort.

Future trends in air conditioning circuit boards focus on the following areas:

Higher energy efficiency: With the global emphasis on energy saving and emission reduction, future air conditioning circuit boards will use more efficient components and optimized designs to reduce energy consumption.

Intelligent: It will be more deeply integrated with the smart home system to support seamless connection with other devices (e.g., smart sensors, home management system) and realize whole-house intelligent control.

Environmentally friendly materials: More consideration will be given to environmental friendliness and sustainability in the selection of materials, with the use of low environmental impact materials such as recyclable materials and non-toxic coatings.

Self-diagnostics and maintenance: Future circuit boards may have self-diagnostic features that can provide timely alarms and prompts for maintenance to enhance user convenience and safety.

As a core component of the air conditioning system, the air conditioner circuit board assumes important control and management functions. With the continuous progress of science and technology and materials, the future of the air conditioning circuit board will not only have a significant improvement in performance, but also in the intelligent, environmentally friendly and other aspects of the value will also show higher.