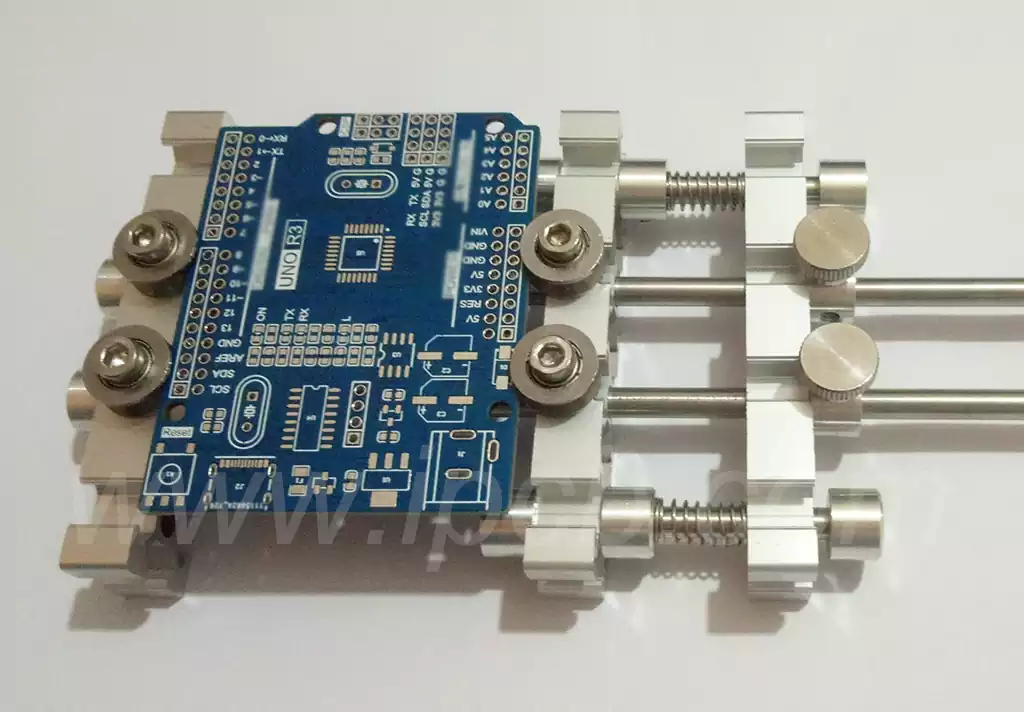

A pcb board clamp is a device used to hold a circuit board in place and is designed to provide firm support to ensure that the board does not move or deform during soldering, testing or assembly, which is critical to ensuring the quality and functionality of the board. Fixtures are usually made of high-strength materials to withstand pressure and temperature changes during operation.

The types of circuit board test fixture varies according to their purpose and principle of operation, and mainly include:

Soldering fixtures: Used to hold circuit boards in place during the soldering process to ensure that the soldering is secure and accurate.

Test fixtures: Used to quickly connect circuit boards to test instruments for electrical performance testing. Good design can improve the accuracy and efficiency of testing.

Separation Fixture: A fixture that separates multiple circuit boards in circuit board processing to help save space and increase productivity.

PCB board clamp is typically manufactured from a variety of materials including metal, plastic and composite materials. Different materials have their own unique advantages and disadvantages, affecting the performance and applicability of the fixture.

- Metal Materials

Advantages:

High strength and durability: metal materials such as aluminum and steel have high strength and can remain stable and not easily deformed under a variety of working conditions, which is critical for the long-term use of fixtures.

Good Thermal Conductivity: Metals have good thermal conductivity and can effectively withstand high temperature operating environments, making them suitable for use in circuit boards that require heat treatment.

Disadvantages:

Heavier weight: metal fixtures are typically heavier than plastic fixtures, which can make handling and operation more difficult.

Corrosion problems: Untreated metal materials are susceptible to oxidation and corrosion, which can affect the life and stability of the fixture. Therefore, additional surface treatment is required to prevent corrosion.

- Plastic materials

Advantages:

Lightweight and Economical: Plastic fixtures are usually lighter, reducing the overall weight of the equipment, making it easier to handle and transport, while manufacturing costs are also relatively low.

Easy to mold: plastic materials can be molded into a variety of complex shapes, improving the adaptability of the fixture and facilitating the use of a variety of circuit boards.

Disadvantages:

Lower thermal resistance: plastic materials have limited high temperature resistance and are prone to deformation in high temperature environments, which may affect the stability of the fixture.

Insufficient mechanical strength: when subjected to gravity or pressure, plastic fixtures may not be as reliable as metal fixtures, and long-term use may lead to deformation.

- Composite Materials

Advantages:

High strength and light weight: Composites combine the advantages of metals and plastics to provide high mechanical strength while keeping weight low.

Excellent Thermal Properties: Composites usually have good thermal properties and can adapt to a variety of heat treatment processes, enhancing the stability of the fixture.

Disadvantages:

Higher cost: composites tend to cost more to produce than metal and plastic fixtures, which may affect their economics in some applications.

Manufacturing complexity: Complex geometries can be more difficult to manufacture and need to be handled through special processes, which can extend production times.

The design of pcb board clamp plays a vital role in electronics manufacturing, and its main purpose is to ensure that the circuit board in the soldering, testing and assembly process to maintain a solid and accurate.

- Stability principle

The fixture must be able to hold the board stably throughout the operation to prevent any kind of displacement or deformation. This is particularly important for soldering and high-precision testing, as any small movement can lead to poor connections or circuit failures. Therefore, it is necessary to choose the right clamping structure and material during design to ensure stability under different operating conditions. - Principle of Adaptability

The design of fixtures must take into account the diversity of circuit boards, including different sizes, shapes and thicknesses. Fixtures should have a certain degree of flexibility in order to quickly adjust and adapt to different types of circuit boards, which helps to improve productivity and reduce changeover time. This principle is particularly applicable to multi-species, small batch production environment. - Ease of operation principle

The design of the fixture should take into account the ease of operation, to ensure that the operator can easily complete the fixing and release of the circuit board. A well-designed fixture can simplify the operation process, reduce human error and improve work efficiency. Priority should be given to easy clamping and ergonomics in the design. - Safety principle

In the fixture design, safety is a factor that can not be ignored. Fixture not only to ensure that the board is fixed and reliable, but also need to avoid accidental operation caused by injury or equipment damage. The design should take into account all possible operating scenarios, and to ensure that in any case the operator can safely use the fixture. - Economy principle

Fixtures should be designed to minimize manufacturing and maintenance costs while ensuring functionality and performance.This includes the selection of suitable materials and production processes to obtain the best value for money.In the design, reasonable structural design and material selection can effectively control costs, while meeting production requirements.

PCB board clamp plays an important role in the electronics manufacturing process,its main role includes stable clamping, accurate positioning, improve soldering efficiency, as well as support for testing and assembly and other functions.

1.Stabilizing Clamping

The primary function of the pcb board clamp is to securely hold the circuit board to ensure that the circuit board will not be displaced or deformed during the soldering or assembly process. This function is essential to ensure the accuracy and efficiency of the soldering process, to ensure that a variety of electronic components in accordance with the design requirements of the correct installation.

2.Accurate positioning

Fixtures provide the necessary positioning support during the processing and assembly of circuit boards.Through the design of reasonable fixtures,can ensure that the circuit board in the welding or other processes are always maintained in the intended position,to avoid the offset caused by poor contact or functional failure. This positioning function is particularly suitable for precision manufacturing requirements of high electronic products.

3.Improve soldering efficiency

The use of pcb board clamp can significantly improve soldering efficiency. Properly designed fixtures can reduce operating time, reduce manual labor intensity, while improving productivity. For example, some fixtures use mechanical or pneumatic devices to achieve rapid clamping and release, so that the operation is more convenient, thus improving overall productivity.

- Support for testing and assembly

Fixtures not only play a key role in the soldering process, but also play an important role in the later functional testing and board assembly. Test fixtures can quickly and accurately connect circuit boards to test equipment, ensuring the accuracy and reliability of test results.In addition,fixtures are also used to assist in the subsequent assembly of circuit boards, improving the stability and efficiency of the overall assembly process.

PCB board clamp plays an indispensable role in the electronics manufacturing process, which not only ensures the stability and precise position of the circuit board, but also significantly improves production efficiency and product quality. Through rational material selection and scientific design, fixtures can meet the needs of different circuit boards, helping the modern electronics industry to gain an advantage in the competition. Choosing the right circuit board fixtures is an important guarantee for efficient and high-quality manufacturing.