The moisture resistance of FR4 PCBs is directly linked to the stability and longevity of electronic products. Material selection, process optimization, and strict environmental control are all indispensable. Only through sustained technical refinement can a robust defensive barrier be built for the electronic world.

The Fundamental Nature of FR4 Water Absorption

FR4 is not a completely inert, non-absorptive material. Its water absorption originates from its material composition and microstructure. FR4 laminates are composed of epoxy resin as the bonding matrix and woven glass fiber cloth as the reinforcing framework. After lamination, numerous microscopic pores and intermolecular gaps remain within the structure. Moreover, hydrophilic functional groups—such as hydroxyl groups—along the epoxy resin molecular chains exhibit strong affinity for water molecules. This intrinsic affinity is the fundamental cause of moisture absorption in FR4.

FR4 water absorption refers to the percentage increase in weight due to absorbed moisture relative to the dry weight of the laminate under specified conditions. This parameter directly reflects the substrate’s ability to resist moisture ingress.

The industry follows well-defined test standards, most commonly IPC-TM-650 Method 2.6.2.1. In this method, FR4 test coupons (typically 100 mm × 100 mm × standard thickness) are dried to constant weight, immersed in distilled water at 23 °C ± 2 °C for 24 hours, surface-dried, and then reweighed to calculate the water absorption rate. For standard grades, conventional FR4 typically requires a water absorption ≤ 0.15%. High-Tg FR4, benefiting from resin modification, can achieve ≤ 0.12%, while automotive-grade and high-reliability industrial FR4 must meet more stringent requirements, often ≤ 0.10% through specialized processes.

It should be noted that the water absorption of FR4 PCBs is not a fixed value and is influenced by multiple factors. Thinner substrates have a higher surface-area-to-volume ratio and therefore absorb moisture more rapidly. Board edges, cut surfaces, and drilled hole walls expose the internal laminate structure and serve as primary moisture ingress paths. In addition, high temperatures during soldering can damage the resin network; if the board is subsequently exposed to humid air during cooling, moisture penetration is accelerated, resulting in increased overall water absorption.

Moisture Ingress Pathways in FR4 PCBs

Moisture-related degradation of FR4 PCBs is a progressive process. Water penetrates along specific pathways, gradually compromising insulation integrity from the surface inward. These pathways often correspond to inherent weaknesses in manufacturing and application processes, becoming critical entry points for moisture.

Board edges and cut surfaces are the most significant ingress routes. During routing or milling, the cutter disrupts the resin–glass fiber interface at the edges, creating rough cross-sections that expose numerous hydrophilic groups and microvoids. In humid environments, water molecules rapidly penetrate these voids through capillary action and diffuse toward the board core. For FR4 PCBs without edge sealing, exposure to high humidity (relative humidity > 85%) can cause moisture content at the edges to exceed safe limits within as little as 72 hours.

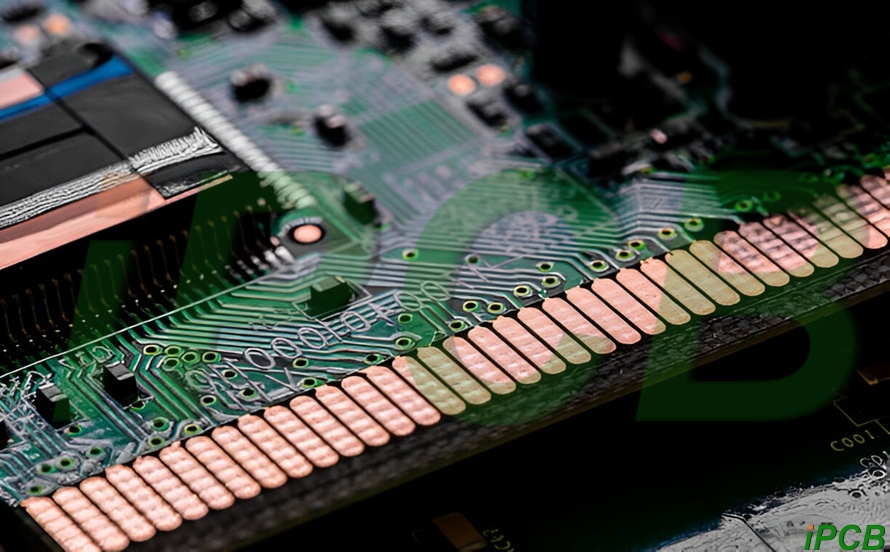

Drilled holes and via walls represent another major vulnerability. Drilling generates resin debris and glass fiber fragments that, if inadequately removed, readily absorb moisture. Furthermore, microcracks may form in the resin layer along hole walls, providing channels for moisture to penetrate into the laminate and even reach the plated copper. In high-density interconnect (HDI) FR4 PCBs, the increased surface area of microvias further elevates moisture ingress risk. Over time, this can lead to copper oxidation along via walls and a reduction in insulation resistance.

The interface between the substrate and copper foil also presents latent risks. During lamination, insufficient resin flow or improper temperature and pressure parameters can create microvoids between the copper foil and the base material. These voids act as moisture reservoirs. Once moisture enters, it is difficult to expel, and prolonged accumulation degrades adhesion strength, impairs insulation performance, and may cause copper lifting or delamination. In addition, surface scratches and microcracks around pad edges can further facilitate moisture penetration.

Impact of Moisture on the Insulation Performance of FR4 PCBs

Once moisture infiltrates an FR4 PCB, it degrades insulation through both physical and chemical mechanisms, leading to performance deterioration and, in severe cases, functional failure. While manifestations vary across applications, the core risks can be summarized in four key aspects.

Significant reduction in insulation resistance is the most direct effect. In dry conditions, FR4 exhibits a volume resistivity on the order of 10¹⁴–10¹⁶ Ω·cm. After moisture absorption, water molecules ionize slightly and dissolve ionic contaminants within the substrate, forming conductive paths that dramatically reduce both volume and surface resistivity. When water absorption exceeds 0.2%, insulation resistance may drop below 10¹⁰ Ω·cm, greatly increasing the risk of leakage or dielectric breakdown in high-voltage applications. For example, FR4 PCBs used in industrial control equipment may experience a two-order-of-magnitude drop in insulation resistance after six months in humid workshop environments, resulting in signal instability.

Degradation of dielectric properties adversely affects signal integrity. The dielectric constant (Dk) and dissipation factor (Df) of FR4 are critical parameters for signal transmission. Absorbed moisture alters the dielectric behavior due to the polarity of water molecules, increasing Dk and dielectric loss. In high-frequency PCBs, this leads to greater signal attenuation, increased crosstalk, and reduced transmission stability. Elevated dielectric loss also causes additional heat generation, which further accelerates moisture ingress and insulation aging, forming a self-reinforcing degradation cycle.

Electrochemical migration (ECM) poses a concealed yet severe risk. Under humid conditions, surface moisture dissolves copper ions generated from pad and trace oxidation. Driven by an electric field, these ions migrate toward the cathode and gradually form conductive metallic filaments—primarily copper dendrites. Once these filaments bridge adjacent pads or traces, short circuits occur. ECM failures are most common in fine-pitch and high-density areas and are difficult to detect in early stages, often manifesting suddenly during operation. Studies indicate that when relative humidity exceeds 80%, the risk of electrochemical migration in FR4 PCBs increases by more than fivefold.

Accelerated substrate aging and reduced structural reliability are long-term consequences. Moisture disrupts the chemical bonds between epoxy resin and glass fibers, leading to resin embrittlement and interfacial separation. Over time, mechanical properties such as flexural strength and impact resistance deteriorate, increasing susceptibility to cracking and delamination. Simultaneously, the combined action of moisture and oxygen accelerates copper corrosion, and the resulting oxides further impair insulation and may even cause conductor breakage. In outdoor or marine climates, moisture-related issues can reduce the service life of FR4 PCBs by 30%–50%.

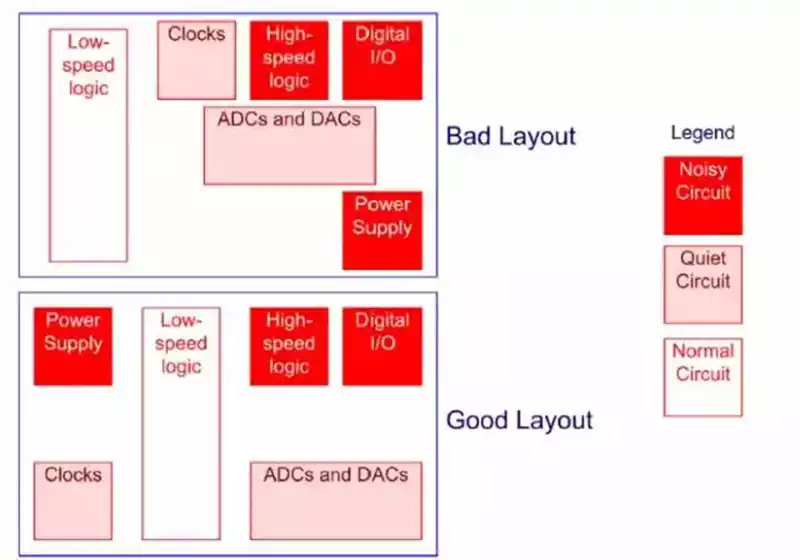

Process Optimization for Moisture Protection in FR4 PCBs

Effective process optimization should focus on three core stages.

First, substrate preconditioning: FR4 laminates must be stored in dry environments (relative humidity ≤ 50%) upon receipt to prevent premature moisture uptake. Prior to use, pre-baking is required based on storage duration; FR4 PCBs stored for more than 72 hours must undergo baking before entering subsequent processes.

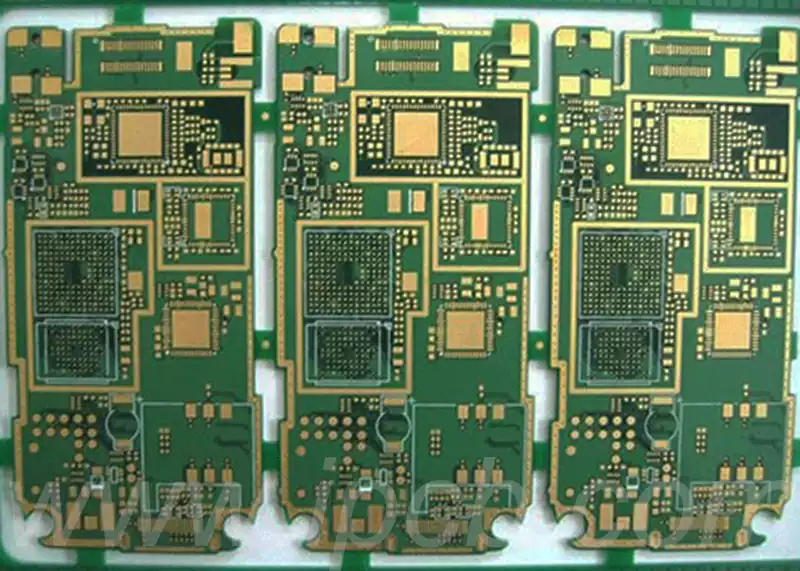

Second, manufacturing process control: After cutting and drilling, prompt edge treatment and thorough cleaning are essential to minimize moisture adsorption during process intervals. Lamination parameters—temperature, pressure, and dwell time—must be precisely controlled to ensure adequate resin flow and minimize internal voids.

Third, enhanced post-process protection: For high-humidity applications, a dual protection strategy combining conformal coating and edge sealing is recommended. Conformal coatings must be applied uniformly, without missed areas or air bubbles, to ensure effective moisture isolation.

As the electronics industry advances toward higher density and greater reliability, the moisture resistance of FR4 PCBs has evolved from a secondary consideration into a decisive factor governing product lifecycle. Enhancing moisture performance requires coordinated improvements in materials, processes, and environmental management, supported by continuous innovation to ensure the long-term reliable operation of electronic systems.