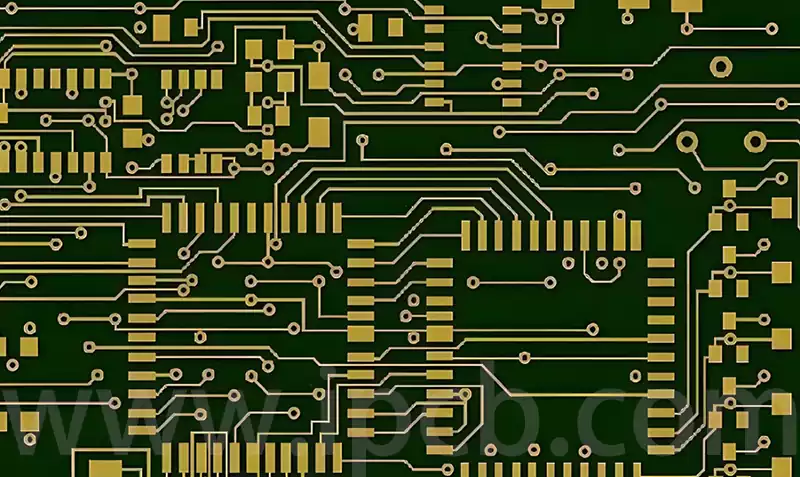

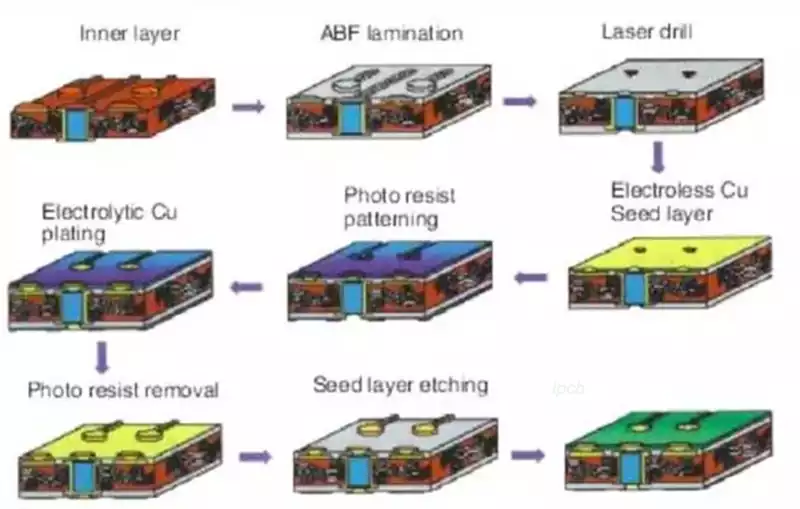

What is msap?It is an advanced printed circuit board manufacturing process designed to produce circuit boards with high precision and excellent performance. The process works by applying conductive materials to the desired circuit pattern and protecting it in unwanted areas, followed by plating and coating of resist layers, and finally by flash etching to remove the excess chemical copper layer, leaving the desired copper-layered circuits.

MSAP PCB technology is an improved solder mask definition process that realizes high-precision line fabrication by precisely controlling the solder mask coating and exposure process. It offers the following significant advantages over conventional PCB manufacturing technologies:

High-precision line production: Through precise control of the solder mask coating and exposure process, it is capable of producing high-precision lines with line widths and spacings as small as 5 mils (0.127 mm), meeting the needs of high-density, miniaturized electronic devices.

Excellent heat and corrosion resistance: MSAP PCBs are made of special solder mask materials with good heat and corrosion resistance, which can withstand high temperatures and a variety of harsh environments, improving the stability and reliability of printed circuit boards.

Reduced production cost: Improved production efficiency, reduced scrap rate, and material waste, thus reducing production cost.

Easy to integrate and assemble: High-precision production process makes it easy to integrate and assemble with other electronic components, improving the reliability and stability of the whole system.

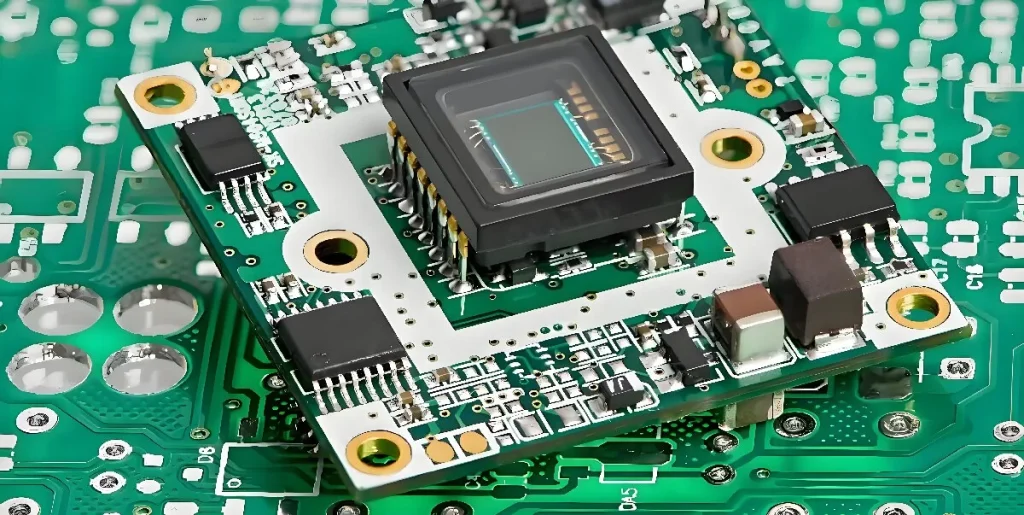

In practical applications, it is widely used in various high-precision and high-performance electronic devices, such as communication equipment, computer hardware, medical equipment, aerospace, and so on. In these fields, electronic devices need to face harsh conditions such as high-density integration, high-temperature operation, and high reliability, and MSAP PCBs, with their excellent performance and stability, have become the ideal choice to meet these needs.

The MSAP process is the most mainstream manufacturing method for fine line carrier boards at present, as the production yield is dramatically improved and the production cost is significantly reduced with little difference in manufacturing accuracy from SAP. Specifically, it can be applied to the production of high-density interconnected printed circuit boards and is capable of achieving a high degree of automation, high throughput, and lean production.

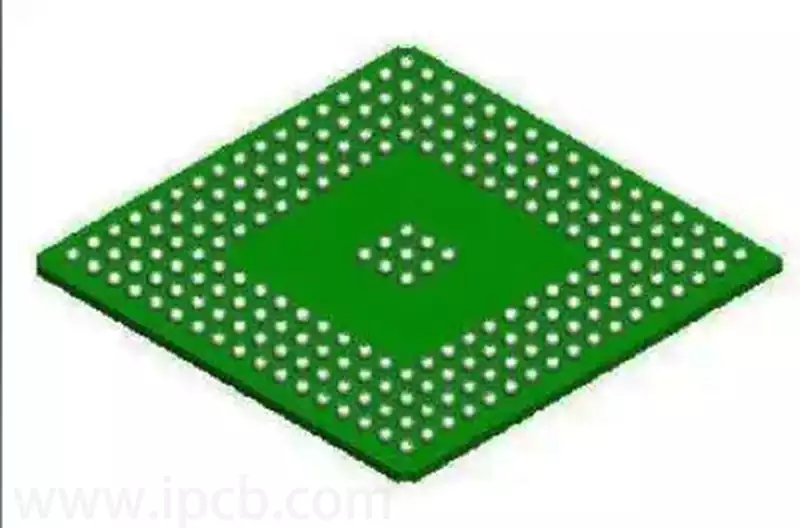

The advantage of MSAP is that it utilizes ultra-thin, low-profile copper foils of 3-5um, which reduces the steps for obtaining ultra-thin copper foils in the semi-additive method, and therefore offers high reliability. In addition, this process can be applied to thinner and smaller motherboard designs.

MSAP PCB, as an advanced PCB manufacturing technology, realizes the perfect fusion of high precision and high performance.