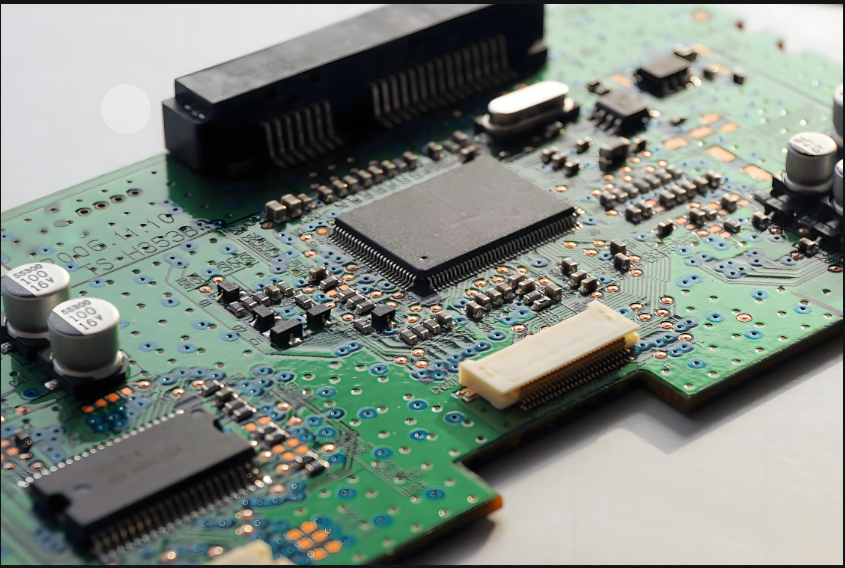

Optical PCB, or Optical Printed Circuit Board, is an advanced circuit board that utilizes optical technology to achieve information transmission and processing. It utilizes optical signals instead of traditional electrical signals, and realizes the transmission and conversion of optical signals on the pcb board through optical components and processes. Unlike traditional electronic signal transmission, it is able to realize faster, more stable and more efficient data communication through the transmission of optical signals.

In the field of high-speed data transmission, the application of optical PCB is particularly prominent. With the popularization of big data, cloud computing and other technologies, the requirements for data transmission speed are getting higher and higher.It is able to realize a faster data rate than traditional electrical signal transmission through optical signal transmission, effectively meeting the demand for high-speed data transmission. This makes it widely used in data centers, supercomputers and other high-performance computing areas.

In addition to high-speed data transmission, it also plays an important role in the field of remote communication. Traditional electrical signal transmission is affected by attenuation and interference when transmitted over long distances, while optical signal transmission is able to overcome these limitations. Therefore, they are widely used in remote communication systems such as satellite communication and fiber optic communication. They not only ensure stable signal transmission, but also improve the reliability and safety of communication.

In addition, optical PCB has a wide range of applications in medical equipment, military and aerospace, automation and intelligent manufacturing. In medical equipment, it can provide precise and fast information transmission and processing capabilities, and improve the performance and reliability of medical equipment. In the military and aerospace fields, it can meet the needs of information transmission in extreme working environments and strict performance requirements. In the field of automation and intelligent manufacturing, it provides fast and accurate information sensing and processing capabilities for robots, automated production lines and other intelligent equipment.

Although optical circuit boards have many advantages, there are also some shortcomings in practical applications:

High manufacturing cost: The manufacturing process is more complex than traditional circuit boards, requiring high-precision optical components and advanced manufacturing processes. This results in relatively high manufacturing costs for optical circuit boards, which may increase the overall cost of the product.

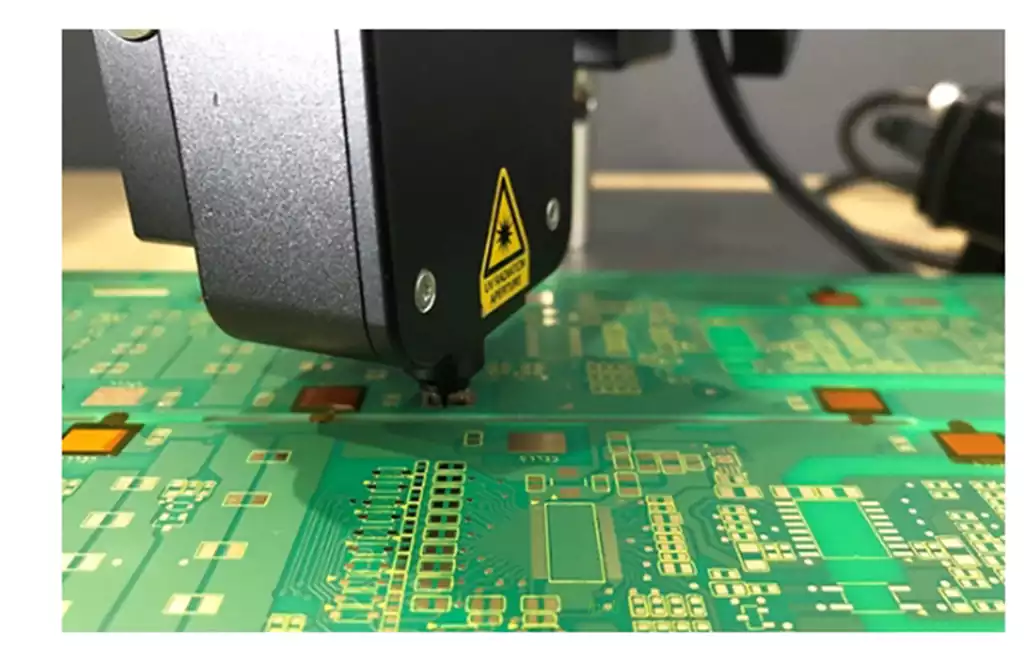

High technical difficulty: The design and manufacturing requires specialized knowledge of optics and electronics, which makes it technically difficult. At the same time, the packaging of optical components and the design of optical circuits require consideration of numerous factors, such as the precision of the optical components and the matching of optical interfaces.

Reliability issues: the reliability of optical pcb may be lower compared to traditional circuit boards. The connection of optical components and the stability of optical interfaces may be affected by environmental factors such as temperature and vibration, resulting in degradation or interruption of optical signal transmission quality.

Difficulty in Repair and Replacement: Due to the complexity of the structure, repair and replacement may be relatively difficult in the event of a malfunction. In addition, damage to optical electronic components may require specialized personnel for repair and replacement, increasing maintenance costs and time.

With its unique technological advantages, optical circuit boards have shown a broad application prospect in many fields. With the continuous progress of science and technology and the increasing demand for applications, its fields of application will be further expanded.