PCB plating to fill vias is a treatment performed to connect different layers of circuits during the manufacturing process. In the manufacturing of High Density Interconnect (HDI) boards and multilayer boards, the treatment of microvias (via) is a key aspect. Conventional mechanical drilling methods can no longer meet the high precision requirements of microvias, and chemical plating and electroplating hole-filling technologies have emerged. Through the combination of chemical plating and copper plating, the plating process fills the microvia completely, thus achieving efficient signal transmission and structural stability.

The basic principle of PCB plating hole filling:

- Hole formation: The process of pcb plating and filling holes on PCB boards is usually carried out with holes pre-formed. The formation of holes can be achieved by mechanical drilling, laser drilling or chemical etching. These holes are often referred to as ‘holes’ (Via).

- Coating of conductive material: After the holes are formed, the surface of the board needs to be coated with a layer of conductive material. This usually consists of a thin layer of copper, which is used to form electrical connections.

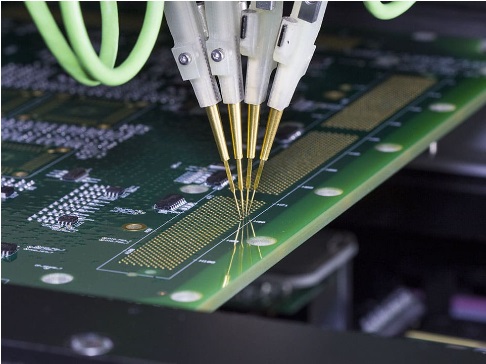

- PCB plating process: The coated conductive material inside the hole needs to be plated to increase its conductivity. Plating of the coated material is usually done by placing the PCB into an electrolyte solution containing metal ions (usually copper ions) and applying an electric current so that the metal ions are reduced and deposited on the surface of the conductive material to form a uniform metallic layer.

- Hole Filling: After plating, the conductive material in the holes forms a metallic coating that increases conductivity. This makes it possible to establish electrical connections between the different layers of the circuit board.

- Residual processing: After plating the holes, some residual processing may be required, such as removing excess coating material or cleaning the surface.

Advantages of pcb plating :

(1) facilitates the design of stacked holes (Stacked) and holes on the plate (Via.on.Pad);

(2) Improves electrical performance and helps in high-frequency design;

(3) Helps dissipate heat;

(4) Plug holes and electrical interconnections in one step;

(5) Blind holes filled with copper plating, higher reliability, better conductivity than conductive adhesive. The process of filling holes with electroplating enables the connection of different levels of circuits on the PCB, thus enabling the design of multi-layer PCBs. This technique increases the wiring density of the board, making electronic devices more compact and efficient.

PCB plating and hole filling takes time and influences:

Circuit board hole filling plating typically takes 1-2 hours depending on the thickness of the board and the size of the filled holes. Thicker boards and larger holes may take longer to fill and cure the electrolyte.

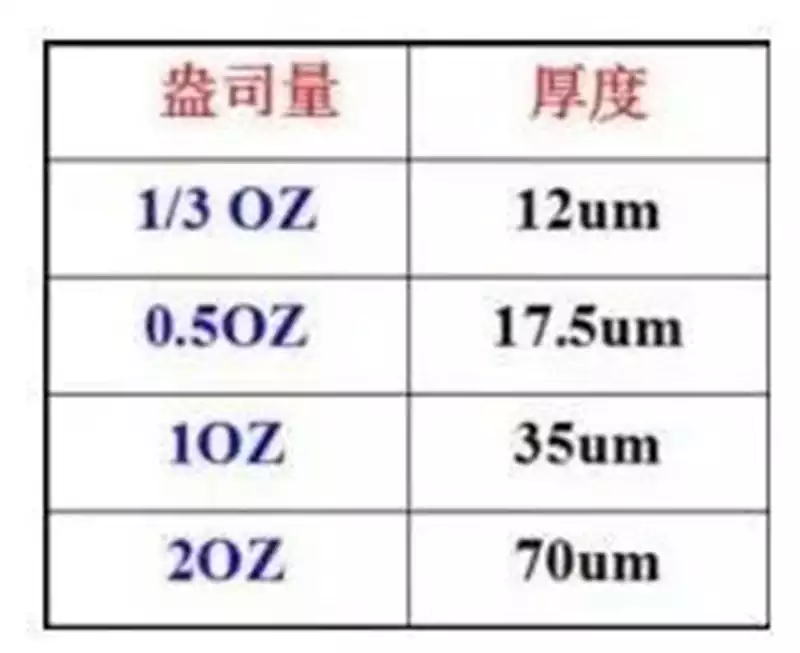

The thickness of the board is a key factor in pcb plating time. Thicker boards mean that the holes need to be filled with more electrolyte. Once the filling is complete, a curing process is also required to ensure that the electrolyte adheres firmly to the hole walls. These steps take some time to complete. Therefore, the thicker the board, the longer it usually takes to fill the holes for pcb plating.

In addition to the thickness of the board, the size of the filled holes will also have an effect on the plating time. Larger holes require more electrolyte to fill, which naturally increases processing time. At the same time, large holes may also require a longer curing time to ensure that the electrolyte adheres evenly and firmly to the hole walls.

In addition to the two main factors mentioned above, there are a number of other factors that may also affect plating time. For example, the composition and pH of the plating solution need to be precisely controlled to ensure that metal ions can be uniformly deposited in the holes. In addition, the thickness and uniformity of the chemically plated copper layer, as well as the PCB surface treatment prior to plating (e.g., cleaning and pre-treatment steps), affect the adhesion and overall quality of the copper layer, which may indirectly affect the plating time.

Challenges and Future Directions of the Hole Filling Process

Despite the many advantages of the hole filling technology, there are still some challenges to be faced in practical applications:

Process Complexity: The combination of chemical plating and electroplating requires precise control of the parameters, and any deviation may result in incomplete hole filling or defects in the hole wall.

Higher costs: The higher material costs of chemical and electroplated copper and the number of process steps increase manufacturing costs.

Environmental pressure: Although the process is gradually becoming more environmentally friendly, the waste treatment of chemical copper plating still needs to be further optimised.

In the future, the development direction of the electroplating hole-filling process will focus on the following aspects:

Green: develop more environmentally friendly chemical copper plating and electroplating copper formulations to reduce the use of heavy metals and organic substances.

Intelligent manufacturing: Improve process stability and consistency through automated equipment and real-time monitoring systems.

New material applications: Explore new substrates and plating materials to accommodate more complex circuit design requirements.

As a key process in PCB manufacturing, pcb plating and hole-filling technology has greatly contributed to the development of multilayer and high-density interconnect boards. Despite the current challenges, with the continuous development and exploration of technology, this technology is bound to achieve more efficient, reliable and environmentally friendly breakthroughs in the future. The continuous improvement of the plating and hole filling process will provide a solid technical guarantee for the miniaturisation and high performance of electronic products, and help the electronics industry to continue to innovate and develop.