With the continuous development of electronic technology, especially the rapid growth of 5G communication, Internet of Things (IoT), smart devices and other fields, the radio frequency (RF) performance of electronic devices has become more and more important. In this process, PCB RF shielding technology came into being and became one of the key technologies that cannot be ignored in modern electronic design. The main role of RF shielding is to avoid the impact of internal or external electromagnetic interference (EMI) on the signal quality of the equipment, to ensure stable and efficient operation of electronic systems.

In this article, we will discuss the principle of PCB RF shielding, application areas, design methods, as well as the challenges and solutions, to help engineers better understand and apply this technology to enhance the performance and reliability of electronic products.

The basic concept of RF shielding

RF shielding, as the name suggests, refers to the interference of RF signals in electronic equipment through physical means to suppress or isolate. Radio frequency interference (RFI) refers to the interference of high-frequency electromagnetic waves on the normal operation of electronic equipment, and this interference usually leads to signal distortion, degradation of communication quality, and even equipment failure. In modern electronic systems, the purpose of RF shielding is to prevent unwanted RF signal leakage or interference, while protecting sensitive circuits from external electromagnetic waves.

In PCB design, RF shielding is not only the protection of signals, but also a strategy to optimize the electronic system. Since PCB is the basic platform for electronic devices, its layout design directly affects the transmission quality of RF signals. Therefore, how to effectively carry out RF shielding has become an extremely important topic in PCB design.

PCB RF shielding principle of operation

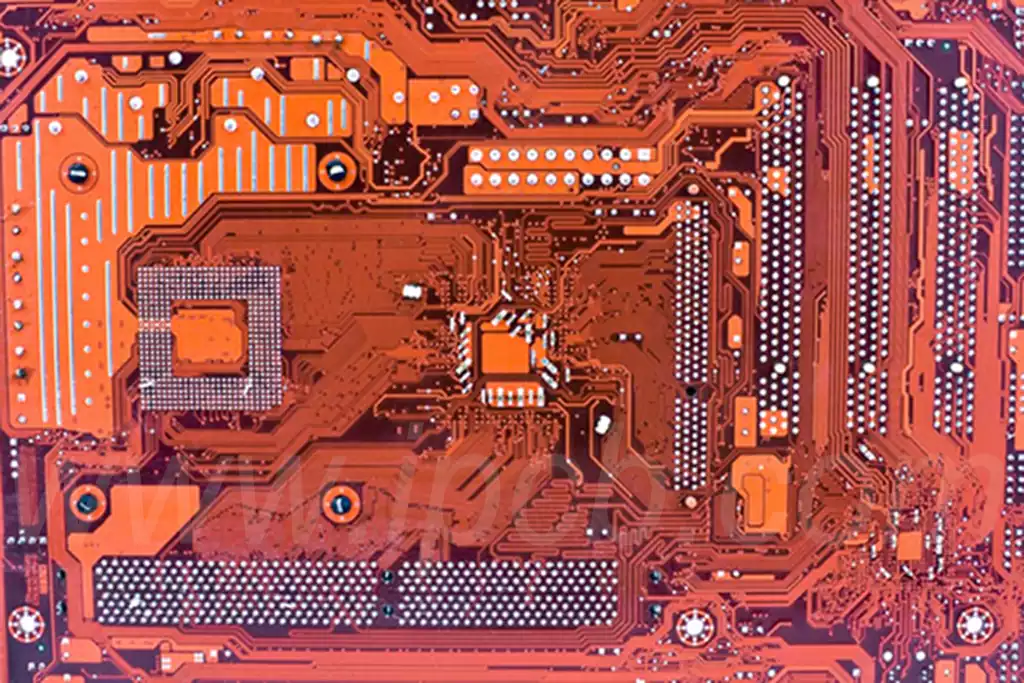

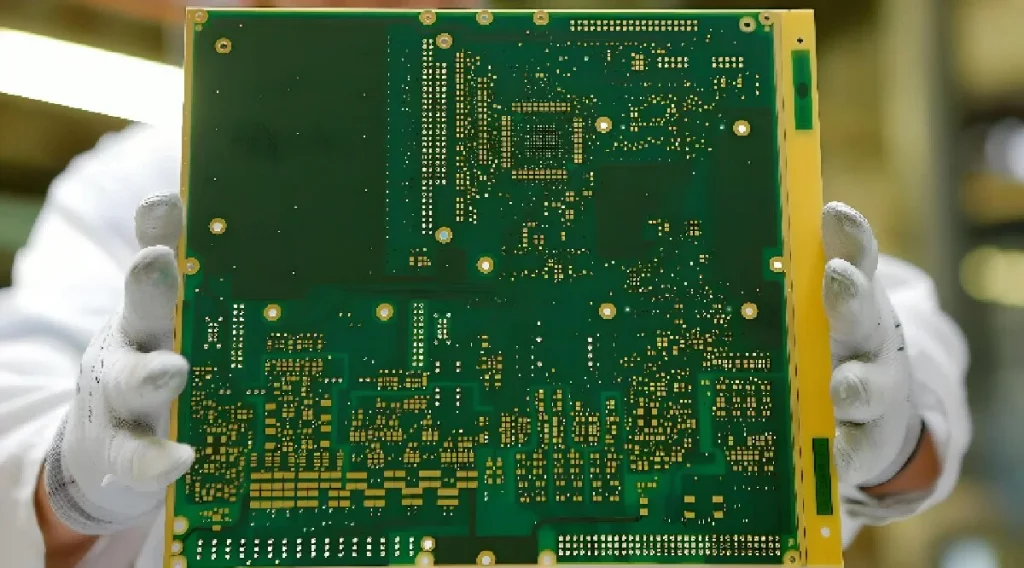

The working principle of PCB RF shielding is mainly through the metal shielding layer added to the surface or interior of the PCB to isolate the transmission path of RF signals. Typically, RF shielding layers use highly conductive metal materials, such as copper, aluminum, stainless steel and so on. These metallic materials effectively reflect or absorb external electromagnetic waves and isolate them to other parts of the PCB, thus avoiding signal interference or leakage.

There are many ways to realize RF shielding on PCBs, and the most common ways include:

Top or bottom metal cover: metal cover is placed directly on the surface of the PCB to form a shielding layer, which can directly block external RF interference.

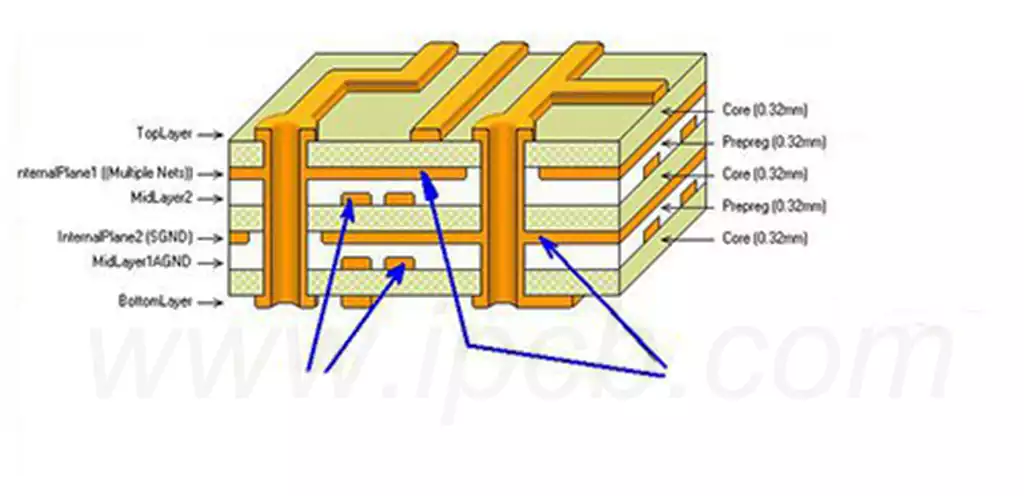

Internal metal layer: In multilayer PCB designs, the RF shield can often be designed as a metal layer inside the PCB, which is electrically connected to isolate it from other circuits.

Metal Cover or Case: For more complex devices, specialized metal covers or cases may be used to encapsulate the PCB. These metal covers and cases effectively isolate RFI sources in the external environment and prevent radiation from the internal circuitry.

The core objective of PCB RF shielding is to provide a low-resistance path for electromagnetic waves to pass through the metal material rather than through sensitive areas of the board, thus ensuring signal integrity and equipment stability.

Application areas of PCB RF shielding

With the continuous progress of science and technology, PCB RF shielding has been widely used in various fields, especially in high-frequency electronic equipment, RF interference on the performance of the equipment is increasingly significant. Below we will discuss in detail PCB RF shielding of several major application areas:

- communications equipment

Communication equipment, especially 5G base stations and wireless communication systems, is the top priority of RF shielding applications. In these devices, RF signals need to be transmitted efficiently, while avoiding signal interference. Therefore, PCB RF shielding technology is widely used in the design of these devices to ensure stability and signal clarity. For example, in cell phones, routers, base stations and other equipment, RF shielding technology can effectively reduce external RF interference and improve communication quality. - Automotive electronics

Modern automobiles contain a large number of electronic devices, such as automatic driving systems, in-vehicle entertainment systems, power control systems, etc., which require very high protection against RF interference. In automotive electronic systems, RF shielding not only prevents the interference of external electromagnetic waves on the vehicle electronic equipment, but also avoids the impact of electromagnetic radiation generated by the vehicle system on the external environment.

With the rise of electric vehicles and autonomous driving technology, the demand for RF shielding in automobiles is increasing. PCB RF shielding technology ensures the normal operation of automotive electronic equipment, but also provides a guarantee for the development of autonomous driving, car networking and other emerging technologies.

- Medical equipment

Medical equipment has extremely high requirements on the accuracy and stability of signal transmission. RF interference may affect the normal operation of medical instruments and even threaten the safety of patients. PCB RF shielding is especially important in devices that are highly dependent on precise signals, such as MRI (Magnetic Resonance Imaging), pacemakers, monitors, and so on.

By applying RF shielding technology in these medical devices, the impact of RF interference on the instruments can be effectively reduced, thus ensuring the accuracy and safety of the devices. For example, pacemakers and implantable medical devices often need to work in a high electromagnetic interference environment, RF shielding technology can effectively reduce the interference of electromagnetic waves on the function of the device.

- Consumer electronics

Consumer electronic products, including smart phones, TVs, laptops and other devices, have become an indispensable part of daily life. With the increasing complexity of the functions of electronic products, the problem of RF interference has become more and more prominent. In the design of these devices, PCB RF shielding technology is widely used to ensure that the signal transmission of the device is not interfered with while avoiding signal leakage.

For example, the Wi-Fi, Bluetooth and NFC functions in smartphones require stable transmission of high-frequency signals, which are easily affected by the surrounding environment. To prevent external electromagnetic interference, RF shields are often used in smartphone PCB designs to protect signal integrity.

- Aerospace

In the field of aerospace, the RF performance of electronic equipment directly affects the safety of communication, navigation and control systems of aircraft. Especially in satellite, radar, aviation communications and other systems, any form of RF interference will bring serious consequences. Therefore, RF shielding is an integral part of PCB design for aerospace equipment.

In order to ensure that the equipment can work stably in complex electromagnetic environments, designers usually use a combination of multi-layer PCB structures and metal shielding to minimize the impact of RF interference on equipment performance.

PCB RF shielding design considerations

When designing PCB RF shielding, there are multiple factors to consider to ensure that the shielding effect is maximized and does not negatively affect the other performance of the device. The following are a few key factors that require special attention during the design process:

- Selection of shielding layer material

The material of the shielding layer is one of the key factors affecting the RF shielding effect. Different materials have different electrical and magnetic conductivity, and these properties will directly affect the shielding effect. In the selection of shielding layer materials, common choices are copper, aluminum, stainless steel and other materials.Choosing the right material can ensure the effectiveness of the PCB shielding layer, thereby improving the anti-interference capability of electronic equipment. - Shielding layer thickness

The thickness of the shielding layer is another important factor affecting the shielding effect. Usually, the greater the thickness of the shielding layer, the better the shielding effect. However, increasing the thickness of the shielding layer may increase the cost and volume of the PCB. Therefore, the thickness and cost of the shielding layer need to be balanced according to the needs of the actual application at the time of design. - Layout of the shielding layer

The layout of the shielding layer also plays a crucial role in PCB design. Usually, the shielding layer should cover the entire RF signal path as much as possible to prevent signal interference. In multi-layer PCB design, RF shielding layer is often located close to the signal layer to ensure signal stability. - grounding design

Good grounding design is the basis of PCB RF shielding. Designers need to ensure that the shielding layer has a good electrical connection to the ground, to avoid electrical isolation between the shielding layer and the ground. Improper grounding design may lead to a decrease in shielding effect, or even introduce additional noise sources. - Distance between RF source and shielding layer

The distance between the shielding layer and the RF source also has an impact on the shielding effect. Usually, a shorter distance can improve the shielding effect, but too small a distance may lead to signal reflection or crosstalk. Therefore, a reasonable design distance needs to be determined according to the specific requirements of the equipment.

Although PCB RF shielding technology plays an important role in many electronic devices, but in the actual application process, designers still face many challenges. Here are some common challenges and their solutions:

- Complexity of high-frequency signals

With the development of communication technology, the frequency of RF signals used in equipment is getting higher and higher, and the difficulty of RF shielding increases. High-frequency signals are more prone to interference and leakage, so more precise shielding designs and more efficient materials are needed to meet these requirements. - Manufacturing process limitations

PCB manufacturing process also has an impact on the RF shielding effect. In multilayer PCB design, how to arrange the shielding layer under the premise of ensuring signal integrity is a challenge. Manufacturing process, process errors and the quality of the inter-layer connection may affect the shielding effect, requires special attention. - Cost and volume constraints

In some applications, the cost and volume of RF shielding may become a bottleneck in the design. How to achieve effective shielding in a limited space, while controlling the cost, is still a challenge for designers.

The future development trend of PCB RF shielding

As technology advances, PCB RF shielding technology will continue to evolve in the following areas in response to growing application requirements and complex electromagnetic environments:

- Higher frequency applications

With the gradual commercialization of 5G communication and future 6G communication technology, PCB RF shielding technology will face more serious challenges. 5G band has a wider range of uplink and downlink frequencies, exceeding the frequency requirements of the 4G era, which means that RF design and shielding technology will be more complex. Future PCB designs need to better support these frequency bands to ensure stable operation of devices in high-frequency environments. - more miniaturized and integrated design

Modern electronic products towards more miniaturization and integration of the direction of development, which also brings greater challenges to PCB design. PCB RF shielding must be completed in a limited space, while not affecting the function of other electronic components. Therefore, how to design a more compact PCB layout, and effectively realize the RF shielding, will become an important direction of future design.

Integrated design not only saves space, but also improves the reliability and performance of components. Therefore, designers need to optimize the design of RF shielding layers within a limited space to adapt to the increasingly compact device space.

- Sustainable and environmentally friendly materials

With the strict enforcement of environmental regulations, the choice of materials in PCB design will also face more challenges. PCB RF shielding requires the use of materials with good environmental protection and sustainability. For example, the use of lead and other hazardous chemicals is being severely restricted, which requires designers to use environmentally friendly materials that comply with RoHS (Restriction of Hazardous Substances) standards.

As materials technology advances, new environmentally friendly materials are beginning to replace traditional materials with better performance and lower environmental impact. For example, certain biodegradable materials and lead-free soldering materials are gradually being used in the production of PCBs, which will provide better options for the application of RF shielding technology.

- Efficient thermal management

In some high-frequency electronic equipment, RF circuits may generate large amounts of heat, which may affect the stability and performance of the equipment. Therefore, how to realize efficient thermal management while ensuring the RF shielding effect has become an important research direction.

In the future, thermal management technology will be closely integrated with RF shielding technology, for example, the use of materials with better heat dissipation or the design of thermal conduction channels will effectively reduce the temperature of the circuit and ensure the long-term stable operation of the equipment.

Summarize

PCB RF shielding technology plays a vital role in modern electronic products, it can not only effectively reduce electromagnetic interference, ensure the stability of signal transmission, but also improve the overall performance of the equipment. With the continuous progress of science and technology, PCB RF shielding technology will continue to develop to cope with higher frequency, more complex application requirements. In the design process, the rational choice of materials, optimize the layout and use of advanced technology will be the key to achieving efficient RF shielding. In the future, with the strict enforcement of environmental regulations and continuous technological innovation, PCB RF shielding will play an important role in more and more fields, promoting the performance and reliability of electronic equipment continues to improve.