PCB silver plating technology refers to the PCB surface covered with a layer of silver metal process. Silver as an excellent conductive material, with good conductivity, oxidation resistance, thermal conductivity and other characteristics. Through the silver-plated processing, PCB conductivity has been significantly improved, while enhancing its oxidation resistance and thermal stability, thereby improving the performance and reliability of the entire electronic system.

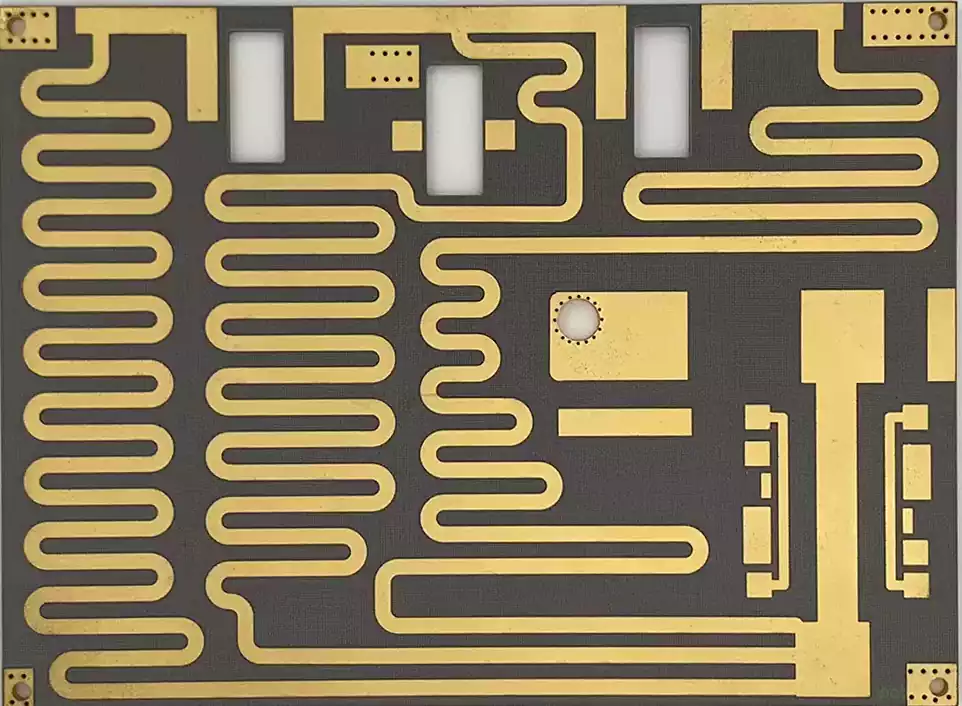

Silver is a white, soft and easy to extend and can be forged metal elements, its thermal and electrical conductivity in any material are the best; silver can be easily dissolved into an ionic solution plated in the need to cover the surface layer of the material silver metal, silver-plating process is as a circuit board to get the way of silver metal, the board surface deposition of silver thickness of only about 0.1-0.5um.

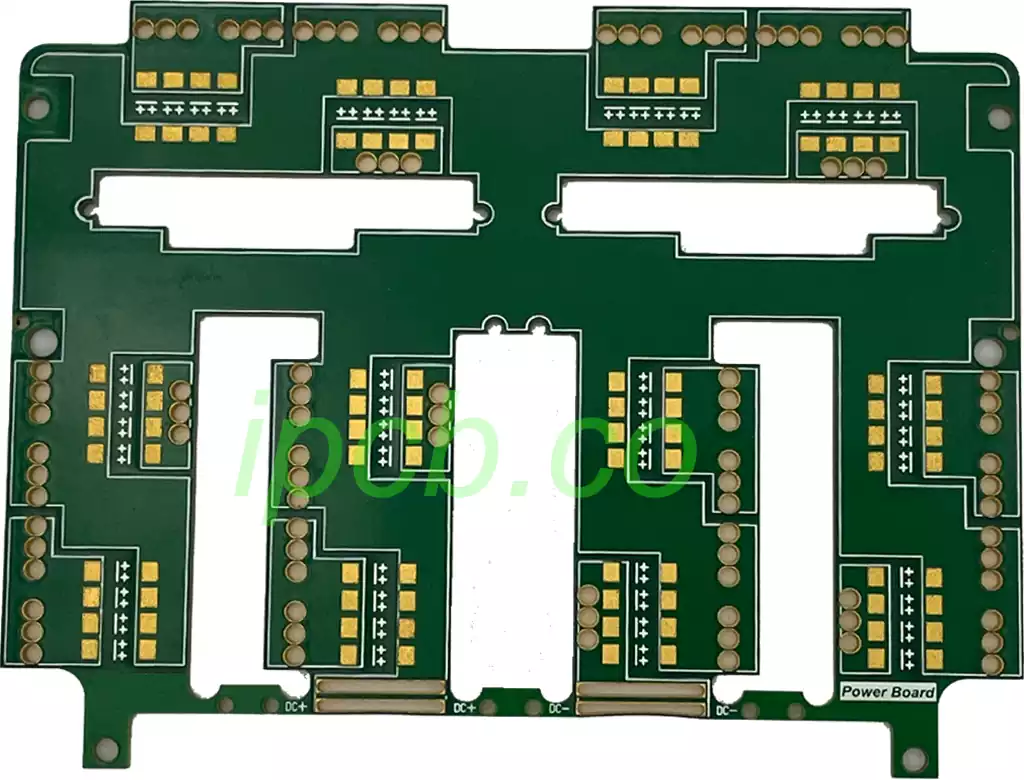

Advantages of PCB silver plating technology

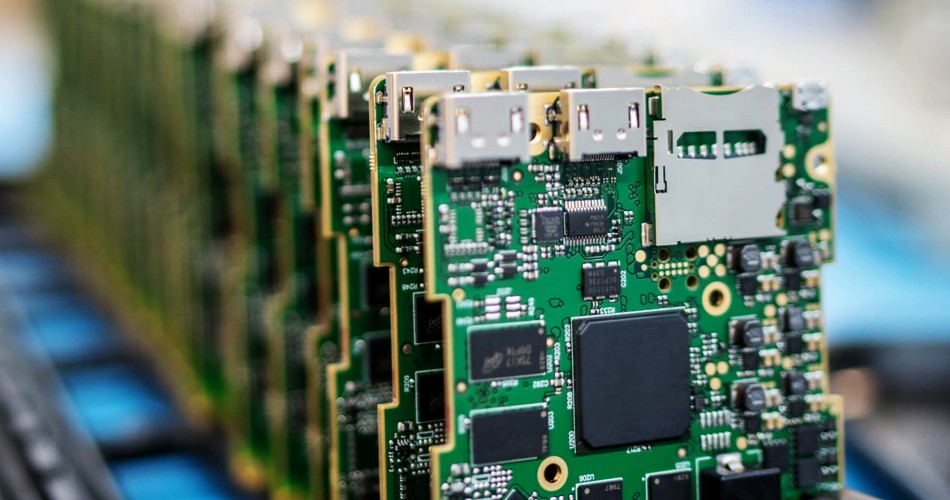

Improved electrical conductivity: The electrical conductivity of silver is better than that of other metals such as copper, so the electrical conductivity of PCBs is significantly improved by silver plating. This helps to reduce resistance and energy loss, improving the transmission efficiency and response speed of electronic devices.

Enhanced antioxidant capacity: Silver has strong antioxidant properties, which can effectively prevent performance degradation due to oxidation on the PCB surface. This helps to extend the service life of PCBs and improve the reliability of electronic devices.

Improved Thermal Stability: Silver has better thermal conductivity and is able to quickly conduct heat to the surrounding environment, thereby reducing the temperature of the PCB. This helps reduce the risk of performance degradation and damage due to high temperatures and improves the stability and reliability of electronic devices.

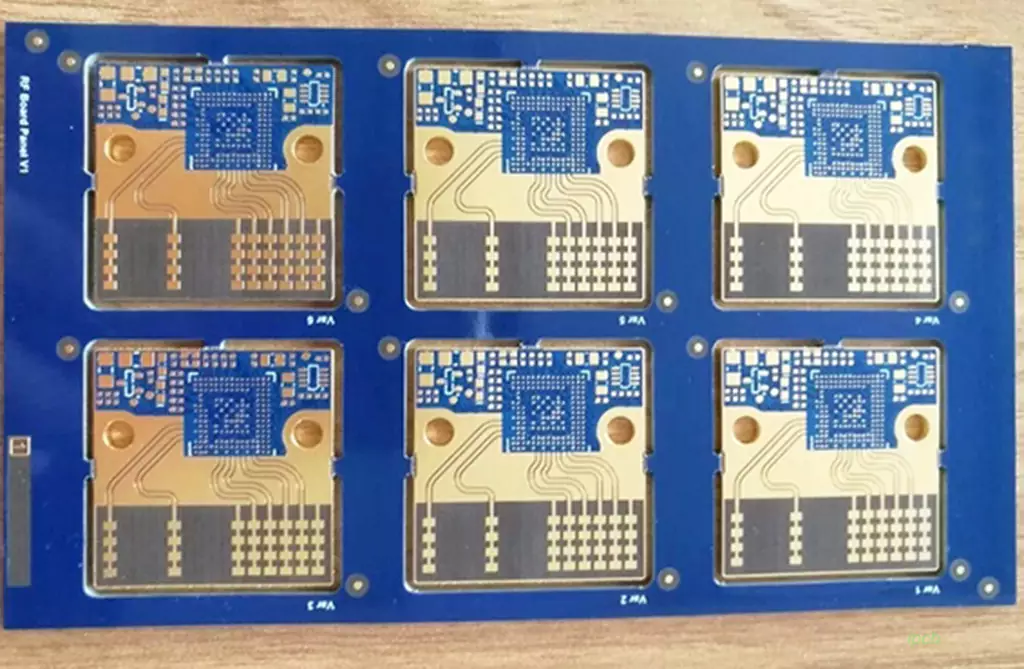

What is the difference between gold plating and silver plating on PCBs?

In terms of appearance, gold plating has a brighter appearance than silver plating. Gold-plated gold appearance gives people a noble and elegant feeling, so often used in high-end electronic products. Silver plating is more gray and elegant. According to different design requirements, you can choose gold-plated or silver-plated to decorate, in order to achieve the product appearance requirements.

Secondly, in terms of electrical conductivity, gold-plated conductivity is better than silver-plated. The conductivity of the metal depends mainly on its conductivity, and the conductivity of gold is higher than silver. Therefore, in the signal transmission process, gold-plated conductivity is better, the current transmission is more stable, can reduce signal attenuation and loss. And silver-plated conductivity is not as good as gold-plated, but also more excellent, suitable for general electronic products.

In addition, gold plating is more corrosion-resistant than silver plating. Gold is a very stable chemical properties of the metal, has a very good corrosion resistance. Therefore, gold-plated PCBs have better durability in humid and corrosive environments, protecting the board from oxidation and corrosion. And silver-plated corrosion resistance is relatively poor, susceptible to oxidation and sulfide effects, so in some of the environmental requirements are not high in electronic products are often used.

Finally, from the cost point of view, silver plating is more economical than gold plating. Silver is a relatively common metal with a relatively low price, so the cost of silver plating is lower. Gold, on the other hand, is a precious metal and is more expensive. Therefore, the cost of gold plating is relatively high, and it is suitable for some high-end electronic devices that require high quality products.

Gold and silver plating on the PCB board in terms of appearance, conductivity, corrosion resistance and cost, there are some differences. Gold-plated appearance is more beautiful, better conductivity, corrosion resistance is stronger, but the cost is higher. The appearance of silver-plated more elegant, better conductivity, corrosion resistance is poor, but the cost is lower. According to different needs and budgets, you can choose the appropriate metal plating to protect the PCB, in electronic products to play a better performance.

PCB silver plating technology with its unique advantages, in the field of electronic manufacturing plays an increasingly important role. From the conductive properties of the enhancement, to the oxidation resistance and thermal stability of the enhancement, silver plating for the PCB has brought a full range of performance upgrades. At the same time, we should also recognize the differences between gold plating and silver plating in terms of appearance, conductivity, corrosion resistance and cost, and these differences make us in the choice of specific needs and budgets need to be weighed.