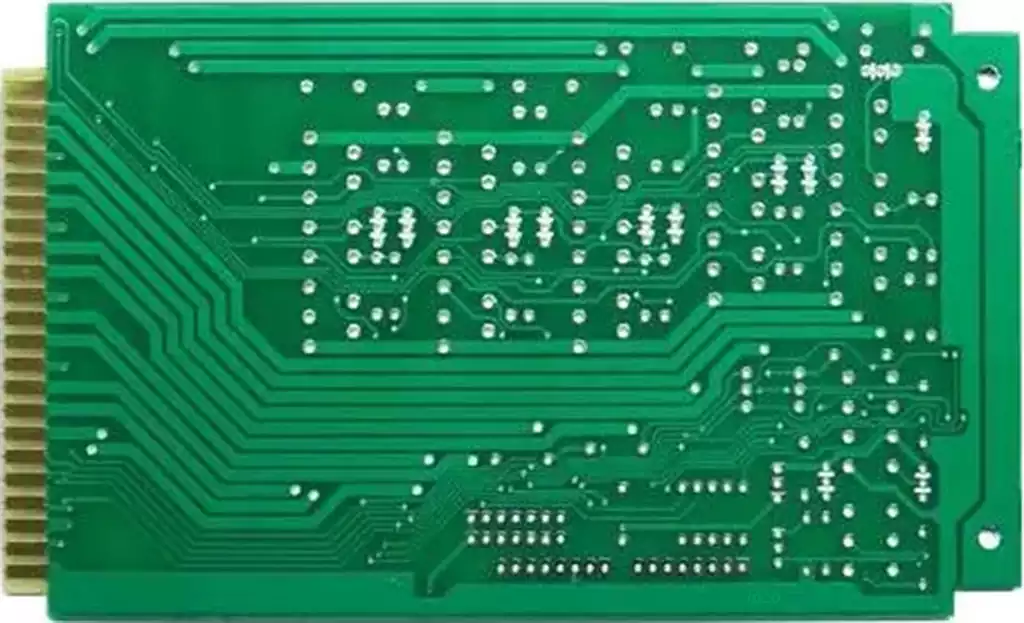

PCB solder pad came off refers to the phenomenon that the solder pad is separated from the printed circuit board. The solder pad is a conductive graphic on the PCB to provide electrical connections, as a necessary medium for soldering electronic components and PCB circuit boards, the solder pads play a vital role in the connection and transmission of the circuit board. Once the pads fall off, it may lead to circuit connection interruption, seriously affecting the function and reliability of electronic equipment.

Circuit board solder pad came off the phenomenon behind the hidden a variety of reasons, mainly including:

Strong mechanical impact,leading to breakage of the connection part.

Circuit board due to long-term use or subjected to substantial temperature changes, making the pad fatigue or fracture.

Improper operation or use,triggering pad breakage.

Coping with the pcb solder pad came off the repair strategy

Re-soldering method.Add solder to the location of the dislodged pads and use a soldering station for soldering repair.This is a common means of solving the problem of solder pad came off,but requires the appropriate equipment and professional skills.

Repair paste method.The use of conductive glue or metal glue to repair the glue fixed in the original pad location,and ensure that it is tightly integrated with the circuit board.

Re-wiring method.If the pads off a large area,and then welding or repair paste may not be suitable.In this case,rewiring can be considered, i.e.,running the wires through the board and using a thermal cutter to cut the wires along the edge of the board.

Caution:

After repairing,be sure to test whether the function of the board is back to normal to avoid damage to the entire board.

If glue is used to repair the pads, pay attention to the nature of the glue and its adhesion to the board to avoid additional damage to the board.

When rewiring, make sure that the wires are positioned accurately and evenly spaced to avoid affecting the function of the circuit board.

Measures to prevent solder pad came off

Optimize the soldering process.Reduce the intensity of mechanical impact and reduce the impact of temperature changes on the circuit board.

Improve the circuit board design.Improve the location and connection of the pads to improve the solidity and risk resistance of the pads.

Enhance maintenance and upkeep.Regularly check whether the circuit board is faulty and repair or replace it in time.

PCB solder pad came off is a problem that should not be ignored,and it is directly related to the performance and reliability of electronic equipment.In practice, we need to choose the appropriate repair method according to the specific situation,and focus on the function test after repair to avoid potential problems. At the same time, the implementation of preventive measures is equally important,from the optimization of the welding process,improve the circuit board design to strengthen the maintenance and repair, each link can not be ignored.