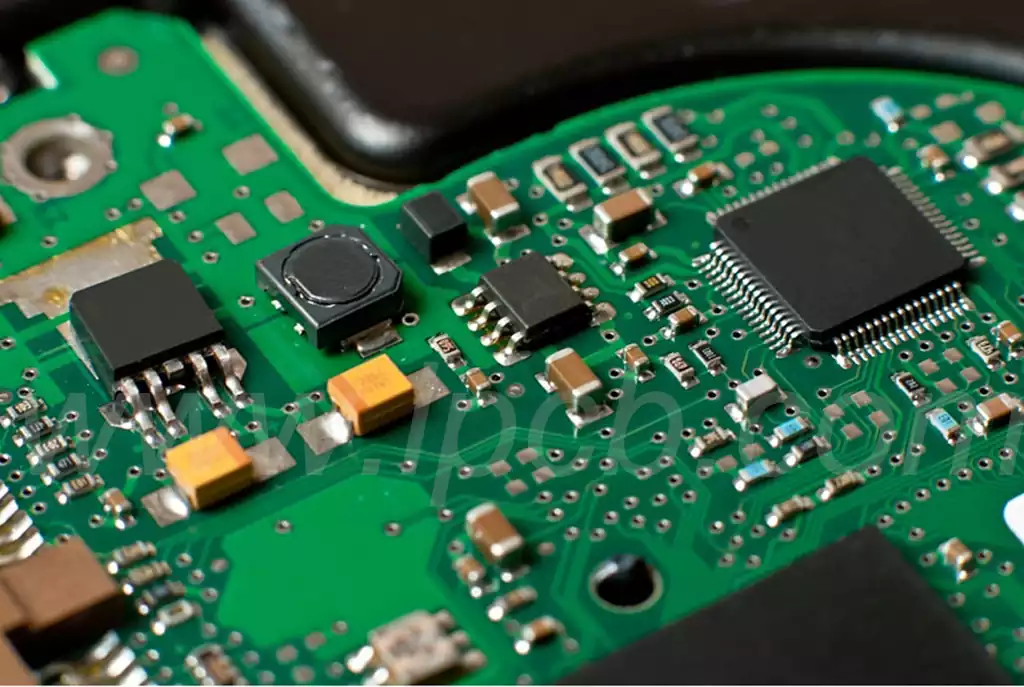

Circuit board in the process of use, often appear pad off, especially in the circuit board repair time, in the use of soldering iron, it is very easy to appear pad off the phenomenon, in this paper on the pad off some analysis of the reasons, and how to fix pcb solder pads put forward some methods.

Reasons for pad fall off

1.Circuit board quality issues, and solder mask mismatch, tin liquid temperature or preheating temperature is too high, too many times when welding, etc., will lead to PCB pads off the temperature is too high. General double-sided board or single panel is easier to pad off, multilayer board has a large area of pavement, fast heat dissipation, the temperature required for welding is also high, it is not so easy to fall off.

- Rework, easy to pad off. Rework usually use a soldering iron repair, the temperature can reach 300-400 ℃, the pad temperature rises instantly, the resin below the welded copper foil by the high temperature fall off, the pad off.

- Circut board moisture. Circuit board moisture, moisture content is too high, so in order to achieve the desired results when welding, will extend the welding time, increase the temperature, easy to cause the circuit board copper foil and epoxy resin delamination, pad off.

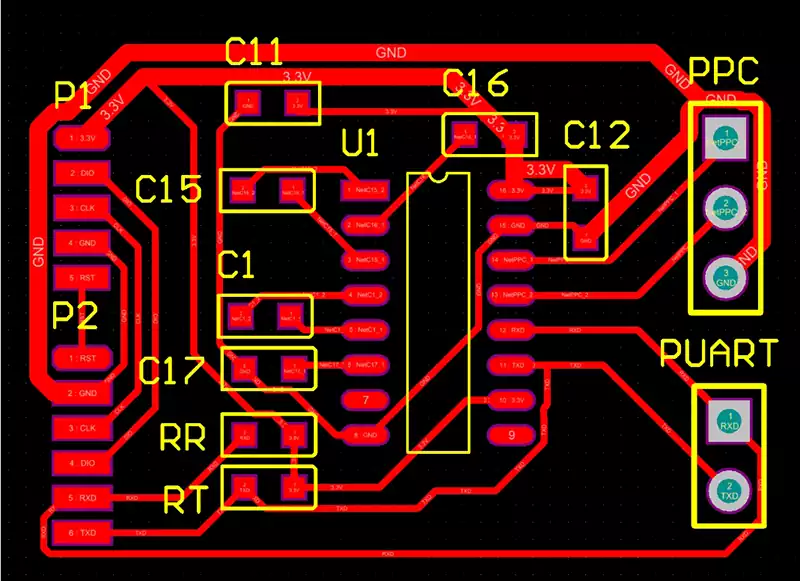

How to fix PCB solder pads

- Re-soldering

Re-soldering is the most commonly used method of repairing pads fall off. First of all, you need to prepare a soldering iron and solder wire, and then the solder wire will be ignited for heating, waiting for the solder wire melted pads will be re-soldered to the PCB board. - The use of conductive glue

Conductive glue is a special glue, you can drop in the location of the pad coated with conductive glue, wait for the conductive glue can be dry. Conductive glue can play a role in connecting the pad and PCB board, but need to pay attention to the adhesion of conductive glue and conductivity. - Use of silver paste

Silver paste is a strong conductive, adhesive repair materials. Silver paste can be applied to the location of the pad drop, the use of electric oven or ultraviolet light to let the silver paste for curing. After curing the silver paste can be a good connection between the pad and the PWB board, but need to pay attention to the amount of use and curing time. - Replacement of pads

Sometimes the pads fall off the damage is more serious, in the case of the above methods can not be repaired, you can consider replacing the pads. Need to purchase the appropriate specifications of the pad and replacement, need to pay attention to the accuracy of the pad and the PCB plate with the matching.

What should I do if the circuit board pads are soldered off?

When the circuit board’s pads fall off during the soldering process due to excessive heating or repeated soldering, we need to take some measures to repair it. First, we should use a cutter to remove the part of the pad that has fallen off up to the edge of the pad that has not fallen off to prevent the circuit damage from spreading further.

If the component pin length is enough, we can scrape off the insulation at the cut-off circuit connector and solder it, and then solder the component pin to this new connector.

If the component pin length is not enough, we can use a piece of thin wire, first on its good solder, and then through the pad holes, one end of the solder on the electronic component pin, the other end of the solder on the pad connector. In order to ensure stability, you can use hot melt adhesive to fix the wire to prevent re-soldering or falling off.

If the situation of pad detachment is serious and the above method is not applicable, we also have the option of flying wire repair. This is done by soldering one end of a wire to the desoldered component pin, and the other end to any available solder joint connected to the desoldered pad.

Another repair method is “bridging”. If the desoldered pad is surrounded by components that are wired to it, we can bypass the damaged pad by soldering the component pins directly to the pins of that neighboring component. Extreme care must be taken when making this repair to make sure that you don’t solder the wiring incorrectly so as not to damage other components.

In the electronics manufacturing industry, the circuit board pad off the problem can not be ignored, it not only affects the quality of the product, but also may lead to production delays and increased costs. By analyzing the reasons for pad fall off, we can find that the quality of PCB boards, improper rework operations and circuit board moisture and other factors are the main reasons. Therefore, in the manufacturing and repair process, we should focus on material selection, process control and environmental management to reduce the risk of pad shedding.