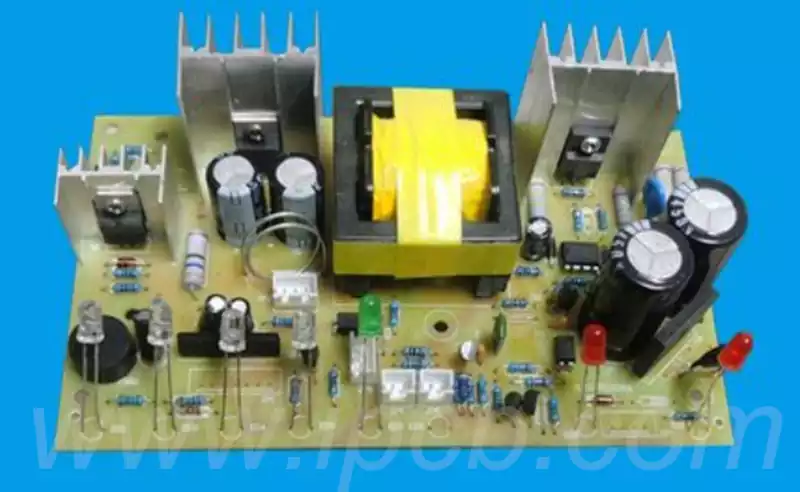

PCB soldering temperature is a crucial parameter in the electronics manufacturing process. It not only affects the quality of soldering, but also directly relates to the performance and reliability of electronic products. Therefore, precise control of PCB soldering temperature is a key step to ensure the quality of electronic products.The proper pcb soldering temperature is generally controlled at about 260°C.

Temperature range for different types of soldering

Depending on the type of soldering, the temperature selected will vary. The common ones are manual soldering, wave soldering and lead-free soldering. Among them, the manual soldering temperature is usually around 260°C, the wave soldering temperature can be between 240-260°C, and the lead-free soldering temperature is generally a little higher, controlled between 260-280°C.

Circuit board soldering temperature is too high is prone to cause the following problems:

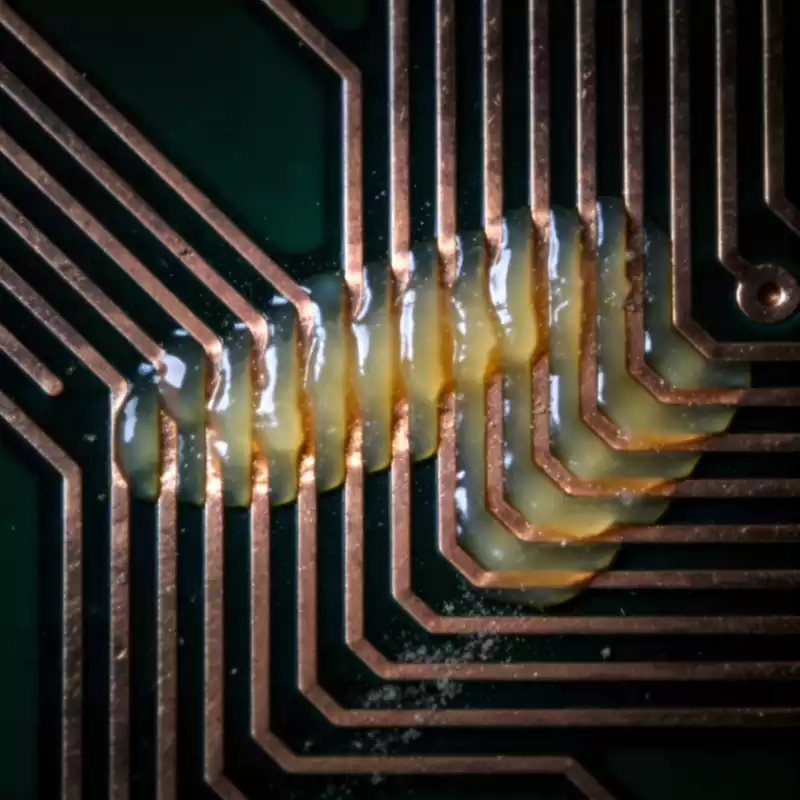

Failure of solder joints

Excessive soldering temperatures may lead to melting of the solder joints or unstable connections, or even trigger the phenomenon of short-circuiting of the solder joints.

Broken wires

Wires or circuits on the board may break due to high soldering temperatures, resulting in broken connections or circuit failures.

Deformation of circuits

Excessive soldering temperatures can cause the board material to expand and deform the board, which in turn affects the mounting and connection of components.

Component Damage

Excessive soldering temperatures may cause damage to the electronic components on the board, as these components are very sensitive to temperature.

Oxidation and Corrosion

Excessive temperatures may cause oxidation or corrosion of metals, which may affect the quality of the connection or even lead to circuit failure.

Thermal Stress Issues

Rapid heating or cooling can create thermal stresses on circuit boards and components, which can lead to cracks, failures or damage.

Notes on temperature when soldering electronic components with solder wire:

(1) Soldering temperatures are required to be performed at relatively low temperatures to ensure that components are not damaged by thermal shock. If the melting point of the solder is between 180-220 ℃, the soldering temperature is usually about 50 ℃ higher than the actual melting temperature of the solder, and the actual soldering temperature is in the range of 220-250 ℃. According to IPC-SM-782, usually chip components are only retained for 10s in a 260°C environment, while some thermal smt components have even lower heat-resistant temperatures. In addition, the PCB will also form thermal stress after high temperature, so the melting point of the solder should not be too high.

(2) molten solder must have good mobility on the surface of the metal being soldered, which is conducive to the uniform distribution of solder, and to lay the foundation for wetting.

(3) The solidification time should be short, conducive to the solder joint molding, easy to operate.

(4) After welding, the appearance of the solder joint should be good, easy to check.

(5) Good electrical conductivity, and sufficient mechanical strength.

(6) good corrosion resistance, electronic products should be able to work in a certain high or low temperature, smoke and other harsh environments, especially military, aerospace, communications and mainframe computers, etc., for this reason, the solder must have good corrosion resistance.

(7) solder raw materials should be a wide range of sources, that is, the metal minerals that make up the solder should be abundant, the price should be low, in order to ensure stable supply.

If the soldering temperature is too high, it will lead to melting of the solder joints or deformation of the pcb board, and in serious cases, it may even lead to burning of the board. If the soldering temperature is too low, it will affect the quality of the soldering, and it is easy for the solder joints not to stick. In addition, if the temperature is too low, it will also lead to a long soldering time, thus affecting productivity.

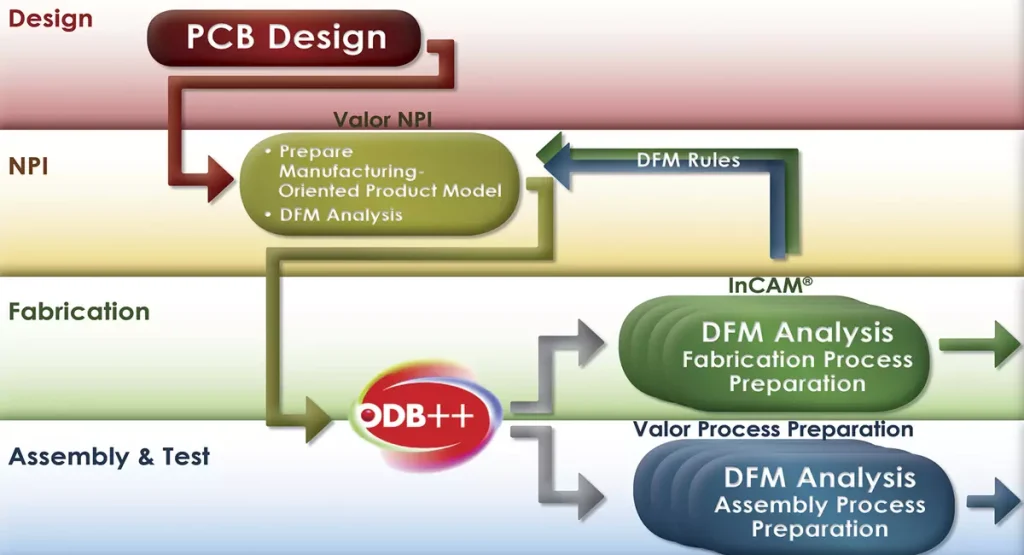

How to control the temperature

In actual production, you can control the welding temperature by adjusting the temperature controller of the welding equipment. In addition, attention should be paid to the selection of appropriate welding tools, as well as the appropriate welding method, so as to ensure that the welding temperature control in the appropriate range.

In the circuit board welding process, the temperature control is critical. The appropriate soldering temperature not only ensures the welding quality, improve productivity, but also effectively prevent the circuit board and its components due to overheating and damage. Therefore, in practice, we should be based on the type of welding and the materials used, a reasonable choice of welding temperature, and by adjusting the parameters of the welding equipment and the selection of suitable welding tools, to ensure that the welding temperature is always controlled within the appropriate range.