Preheating pcb is used to preheat circuit boards that need to be repaired to minimize thermal damage, reduce heat demand on soldering tools, and thus speed up rework.

How to use the preheating pcb

- Wipe the working surface of the heating plate clean, no water droplets, dirt, etc. on it.

- Place the sample bottles or other utensils.

- Turn on the power, close the power switch. Indicator light is on, the electric hot plate is in working condition.

- Adjust the temperature knob, up to the required temperature, the hot plate should be in a working state should be supervised.

- Work is completed, turn off the power switch. Cut off the power supply. 6.

- Wait for the work surface to cool down and clean it up.

What do I need to pay attention to after using the heating pcb?

- After each use, turn the energy switch to the off position, and then turn off the power to use some common cleaning agents and industrial water to avoid the risk of corrosion.

- It is not necessary to unplug the power supply for a long time, put the preheating pcb in a dry place and cover it with a plastic dust cover.

- The instrument must be cleaned before storage and the heating plate must be cleaned. Build

- If the heater is placed for more than 3 months before use, it is best to use intermittent energization to dry itself and exclude moisture.

Preheating is a very important step in PCBA processing. So, what is preheating? Pre-heating refers to a process in which the PCB board is placed on a special heating table for heating before PCBA processing, and the following effects can be achieved through heating:

- Repel surface moisture: Before PCBA processing, the PCB board will always be exposed to the air, so the surface will produce a lot of moisture. If this moisture is brought into the process, it will have an impact on the soldering, placement and plating processes. By pre-heating the PCB before processing can be driven off the surface moisture to ensure that the surface is dry.

- Preheating PCBA components: PCBA components due to long storage, transportation and other factors, will make its surface attached to a lot of impurities. If these impurities are brought into the processing operation, it will adversely affect the quality of the components, spot welding, placement and other processes. By preheating the components, you can remove the impurities and allow them to restore their own characteristics and improve the quality of subsequent processing.

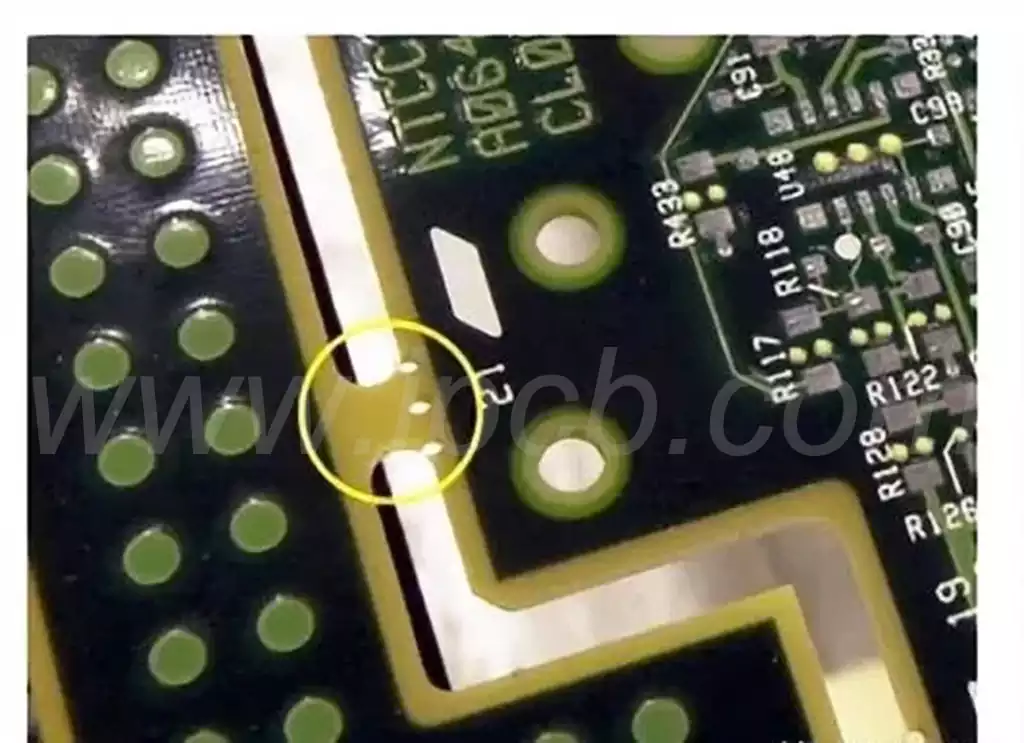

- Prevent PCB soldering rupture: When soldering, the PCB board temperature change is relatively large, which can lead to board contraction or expansion, and this difference can lead to the rupture of PCB soldering. Pre-heating can make the PCB substrate uniformly warm, to achieve the purpose of welding more stable.

- Improve the accuracy of PCBA processing: When performing patch and spot soldering, high temperatures help to speed up the soldering process, improve viscosity and strength, and ensure accuracy. Pre-heating can keep the PCB at a constant temperature during processing and ensure the accuracy of processing.

Precautions for Preheating

In the process of preheating, special attention should be paid to the following matters:

- Temperature: Pre-heating temperature should not be too high, otherwise it may cause damage to the PCB or PCBA components. In general, the preheating temperature of about 100-120 degrees is appropriate.

- Time: Pre-heating time is too long or too short is not good, too long will make the PCBA components saturated, overheating for too long may lead to discoloration and blackening and other phenomena, too short a period of time does not achieve the role of preheating. Pre-heating time is generally appropriate between 2-5 hours.

- Effect: Pre-heating effect must be achieved, and can play a due role in the subsequent processing, if the effect is not ideal, need to re-heat.

- Operator: Pre-heating is not difficult, but improper operation can easily cause damage to PCBA components, thereby affecting product quality. Therefore, the operator must have a certain degree of experience in process operation.

Preheating pcb is indispensable in PCBA processing, which ensures the processing quality and improves the efficiency. Correct use and attention to detail is the key to guarantee product performance.