Printed circuit boards (PCBs) are an important and indispensable part of various electronic devices and are widely used in computers, cell phones, home appliances, and other electronic products.The printed circuit board price is usually affected by a variety of factors, including material cost, production process, size, and number of layers.

What factors affect the printed circuit board price?

Printed circuit board production is the original equipment manufacturer customers belong to the OEM products, different customers ordered products are not the same, there are few shared products, on the other hand, out of quality considerations, some customers may also specify the use of a certain manufacturer’s substrate, or ink, etc., in order to achieve its quality and cost control requirements,so the domestic professional pcb circuit board production exists in the price of the variable.

1.PCB circuit board production materials used (such as material thickness)

To ordinary double-sided board, for example, the board material generally have epoxy board, composite copper clad board, etc., the board thickness from a few millimeters to a few decimeters, copper thickness is also different,all of which in the board material on a huge price difference; in the soldermask ink, ordinary thermosetting oil and photographic green oil also exists in a certain price difference,and thus the material of the different caused by the price of the diversity. The thickness of the copper foil is closely related to the effective use of the material.Thicker copper foils are more expensive and present additional challenges and costs. You may need to use more prepreg in your processing steps to fill in the gaps between the copper. Because thicker copper is heavier, you may also experience higher transportation costs.

2.PCB circuit board production process (i.e. process cost affects price)

pcb circuit board production,different production processes will result in different costs, such as gold-plated boards and tin spraying boards, the production of the shape of the gong (milling) board and beer (punch) boards, the use of silk-screen lines and dry-film lines, etc. will form a different cost, resulting in a diversity of prices. Common: OSP (antioxidant), leaded tin spray, lead-free tin spray (environmentally friendly), gold-plated, immersion gold and some combination of processes, etc., the more the price of the above process the more expensive.

3.Finished product rate affects the price (generally the more advanced technology, the more favorable price)

Customer requirements of the high and low will directly affect the yield rate of the board factory, the yield rate is too low to meet customer requirements, the customer requires a return to the factory, resulting in a different cost of the board factory, and ultimately lead to the price of the product varies.

4.Production of regional part of the impact on the price (generally more favorable than the north of the South)

At present, the domestic geographic location,from south to north prices are different, different regional prices have certain differences, the domestic well-known pcb circuit board manufacturers will generally be adjusted according to the different payment methods PCB prices, and thus the different regions have caused a diversity of prices how to calculate the price of PCB quotes, such as the cost of different areas of the plate costs, drilling costs, process costs have an impact on the price.

5.Mold costs and test racks

(1) mold costs, samples and small quantities, then the general board factory is the use of drilling and milling profile, will not be charged in addition to the milling fee, in doing large quantities will be required to open the mold punching plate, so that there is a set of mold costs, the board factory is generally quoted in the 1,000 yuan upwards.

(2) test fees: sample boards are generally used flying probe test, the board factory generally charge a test fee ranging from 100-400 yuan; batch should be opened to test the test frame to test the test frame of the general board factory’s offer between 1000-1500 yuan.

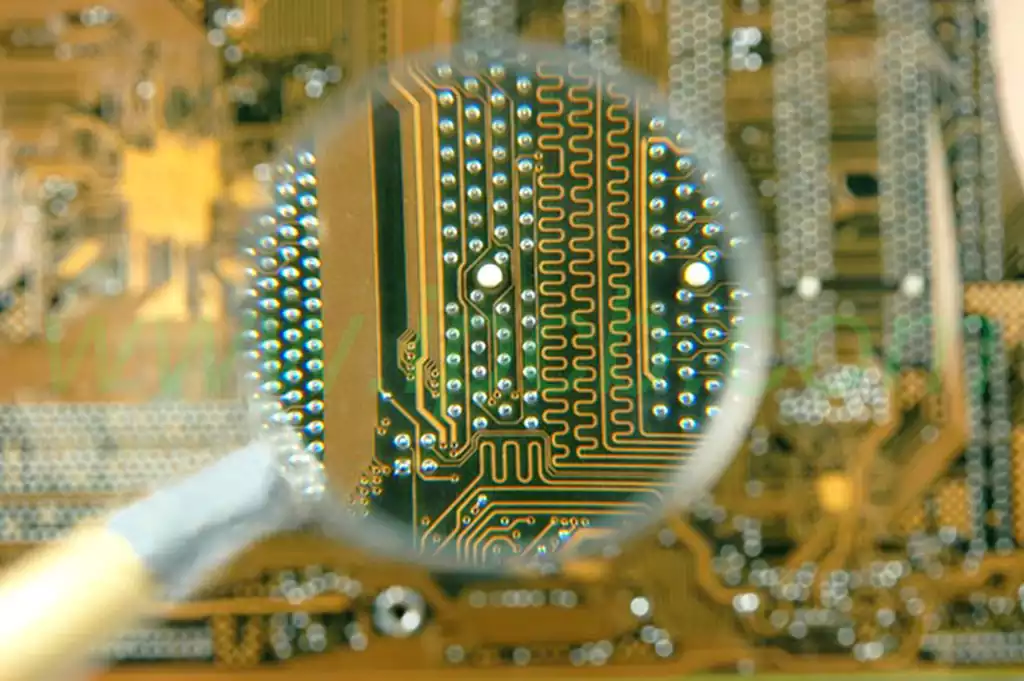

6.PCB itself is difficult to cause price diversity

Two kinds of circuit boards have 1000 holes, a board aperture greater than 0.2mm and another board aperture less than 0.2mm will form a different drilling costs; such as two kinds of circuit boards are the same, but the line width line spacing is different, a kind of are greater than 4mil, a kind of are less than 4mil, will also result in different production costs; Secondly, there are a number of not going to the ordinary board process design is to add money, such as half-hole, buried blind holes, a kind of are less than 4mil, will also cause different production costs; Secondly, there are some do not go to ordinary board process design is also a money. For example, half-hole, buried blind holes, holes in the disk, keypad printing carbon oil.

7.Copper foil thickness caused by different price diversity

Common copper platinum thickness: 18um (1/2OZ), 35um (1OZ), 70um (2OZ), 105um (3OZ), 140um (4OZ), etc., the more the copper foil thickness the more expensive.

8.PCB size

The size and shape of the PCB will affect the increase in cost. Expanding the size of the PCB will require more material and time to manufacture the final product, resulting in higher costs. the price of the PCB will increase proportionally with the surface area of the board, you can use it to calculate how much extra your product will cost when you expand beyond the standard size.

- Number of layers

There are many reasons why adding additional layers increases the cost. When you add more layers, you will need more material for each layer and it will take longer with additional etching and bonding steps.

In addition, adding more layers usually increases the probability that the PCB will encounter defects during the testing phase, so when you request a multilayer board, your manufacturer will probably take this into account in your quote. Your manufacturer will need to check each layer, adding to these costs.

10.Line Width and Spacing

The line of a PCB is essential as it is responsible for its electrical carrying capacity. However, how the lines are arranged on the PCB board and how the design relates to the available space can affect the price. Tighter lines are more challenging for manufacturers, leading to higher prices for these services.

11.Controlled Impedance

As with line tightness, controlled impedance will require the design and production of very specific or uniform trace widths and spacing. Many factors in these processes can lead to higher prices, from the specific materials required to achieve the desired results to the necessary testing procedures.

12.Soldermask, Silk and Carbon Printing

When designing a PCB, you should consider the production steps that your manufacturer will need to complete it. Including soldermask, silkscreen and carbon printing all require separate processes, which will require more time investment.

If the process requires specialized equipment or tooling, the price will also change. For example, if you choose higher quality or thicker soldermask, the material will increase in price.

The printed circuit board price is affected by a number of factors, including the material, production process, size, number of layers and complexity of production. Different material choices, copper foil thicknesses, production processes, and stringent customer requirements can lead to significant price differences. In addition, geographic location, market demand and production scale can also have an impact on the cost of PCBs. Understanding these influencing factors helps customers make more cost-effective decisions when selecting PCBs, improving overall project efficiency and ensuring product quality. These multifaceted factors make up the complexity of the PCB market, making it imperative to conduct a thorough cost evaluation when quoting an order.