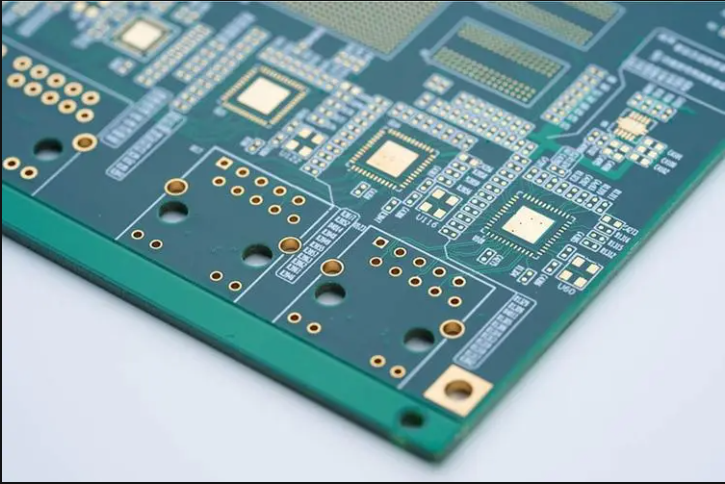

PCB is a printed circuit board, which is the support of electronic components and the electrical connector of electronic components. In modern electronic products, the printed circuit board thickness standard is very important, and different thickness standards have a direct impact on the performance and stability of electronic products. This article will give a detailed introduction to the PCB board thickness standard.

Products and Application Scenarios

First of all, the selection of printed circuit board thickness standards should be determined according to the specific electronic products and application scenarios. – Generally speaking, common PCB board thicknesses include 0.4mm, 0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.6mm, 2.0mm, 2.4mm, 3.2mm, and 6.4mm. Paper-based copper-clad laminates with nominal thicknesses of 0.7 and 1.5 mm and glass cloth-based copper-clad laminates with nominal thicknesses of 0.5 and 1.5 mm are suitable for printed plugs.

The thickness tolerance of the printed plug area is very important, which will affect the reliable contact with the socket, so it must match the selected socket. 1.5mm thick printed circuit boards are widely used in various electronic instruments and equipment. Because this thickness of printed circuit boards is enough to support the weight of integrated circuits, medium and small power transistors and general resistors and capacitors.

Even if the printed circuit board area is as large as 500×500 mm, there is no problem. A large number of sockets are used with printed circuit boards of this thickness. And so on. Different thickness standards are suitable for different electronic products. For example, 0.4mm PCB boards are suitable for light and thin electronic products, while 1.6mm PCB boards are suitable for general household electronic products.

The printed circuit board thickness used for power supply should be thicker because it has to support heavier transformers, high-power devices, etc., and generally 2.0-3.0 mm thick can be used. As for some small electronic products, such as electronic watches, calculators, etc., it is not necessary to use such thick boards. 0.5 mm or thinner is enough.

The thickness of a multi-layer printed circuit board is related to its number of layers. The thickness of a multi-layer board with 8 layers or less can be limited to about 1.5 mm. The thickness of more than 8 layers must exceed 1.5 mm. The thickness between each circuit layer of a multilayer board is often determined by the electrical design.

Although, the market offers a standard thickness of 1.6 mm (0.063 inches). Sometimes, the trace impedance of the circuit board core layer thickness and solder mask coating must be considered. When calculating impedance, the consequences of conformal coating must be considered because the circuit board is usually covered in solder mask. Generally speaking, solder mask reduces the impedance on thin traces. When the trace thickness increases, the impact of solder mask is much smaller

Performance and stability

Secondly, the PCB board thickness standard is closely related to the performance and stability of electronic products. Generally speaking, the thinner the PCB board, the better its thermal conductivity, but the bending and impact resistance are relatively poor; while the thicker the PCB board, the better its bending and impact resistance, but the thermal conductivity is relatively poor.

Therefore, when selecting the PCB board thickness standard, it is necessary to comprehensively consider the working environment and performance requirements of electronic products, as well as the thermal conductivity and mechanical properties of the PCB board.

Manufacturing process and cost

In addition, the PCB board thickness standard is also related to the manufacturing process and cost of electronic products. Generally speaking, the thinner the PCB board, the more complicated its manufacturing process and the higher the cost; while the thicker the PCB board, the simpler its manufacturing process and the lower the cost. Therefore, when selecting the PCB board thickness standard, the factors of manufacturing process and cost also need to be considered.

Finally, with the continuous development and upgrading of electronic products, the requirements for the PCB board thickness standard are also increasing. In the future, as electronic products develop towards thinness, high performance and high reliability, higher requirements will be put forward for the thickness standard of PCB boards, such as thinner PCB boards and higher thermal conductivity.

Therefore, the selection of PCB board thickness standards will become a very important link in the design and manufacture of electronic products.

Summary

In summary, the PCB board thickness standard is an important factor that cannot be ignored in the design and manufacture of electronic products. Its selection needs to take into account the performance and stability of electronic products, manufacturing process and cost and other factors.

In the future, with the continuous development and upgrading of electronic products, the requirements for the PCB board thickness standard will continue to increase, so it is necessary to continuously carry out technological innovation and research and development to meet the needs of the market. I hope this article will be helpful for the selection of PCB board thickness standards. Thank you for reading!