Rogers 4350B is a high-performance polymer material known for its outstanding electrical properties, mechanical strength and stability. It is used in a wide range of electronic, electrical and aerospace applications, providing excellent support for a variety of demanding application scenarios.

Rogers RO4350B high-frequency board board is fully compatible with traditional PCB manufacturing technology, do not need to do through-hole copper-plated special pre-treatment (PTFE plates need to do plasma treatment) or other pre-treatment process, soldermasking process can be milled board. Compared with traditional microwave material laminates are less expensive, so they are widely used for active devices and high-power RF designs that require fire rating UL 94V-0.

Rogers RO4350B sheet has the following characteristics.

1. Low RF loss: Df:0.0037 10GHz;

2. Low dielectric constant: Dk:3.48+/-0.05 and fluctuation with temperature;

3. Low Z-axis coefficient of thermal expansion: 32 ppm/°C;

4. Low in-plate expansion coefficient;

5. Low dielectric constant tolerance;

6. Excellent dimensional stability;

7. Stable electrical characteristics at different frequencies;

8. Processing similar to FR-4, and easy to mass production and multi-layer mixing and pressing of FR4, so it has a great price competitive advantage;

The main application areas of Rogers 4350B:

Aerospace: in the aerospace field, electronic equipment needs to withstand extreme temperature and pressure changes, but also has to have a high degree of reliability and lightweight characteristics.Its excellent performance to meet these requirements is widely used in the manufacture of electronic equipment on aircraft and satellites.

Automotive Electronics: Automotive electronics require high reliability and durability while adapting to the complex environmental conditions inside the vehicle, it meets these requirements and is widely used in automotive electronics for key components such as automotive control modules, sensors, and actuators.

Communication Equipment: Communication equipment requires high-speed signal transmission and high reliability, while also adapting to a variety of complex environmental conditions, its excellent electrical and mechanical properties meet these requirements and are widely used in the manufacture of routers, base stations, and optical modules and other key components of communication equipment.

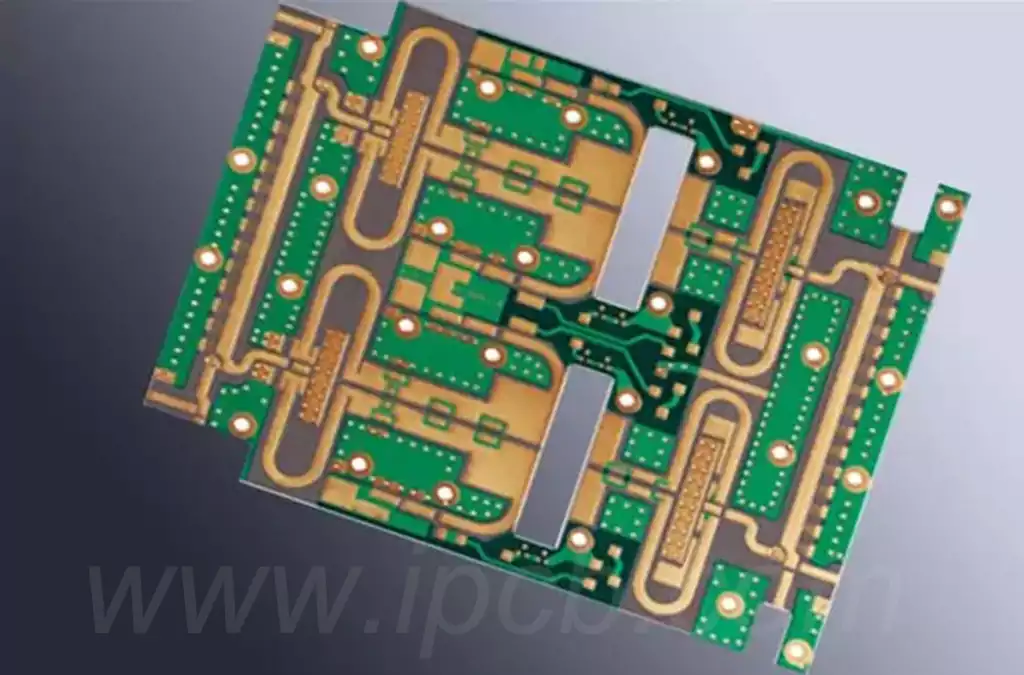

Microwave Applications: With its low-loss characteristics, excels in microwave applications and is used in the manufacture of microwave devices, high-frequency heads (LNBs), and more.

Active Devices and High-Power RF Designs: high dielectric constant and low loss characteristics make it ideal for active devices and high-power RF designs, and it is widely used in the manufacture of RF amplifiers, mixers, filters, and other key components.

Portable Communication Devices: Due to its lightweight and high reliability, Rogers 4350B is also widely used in portable communication devices, such as cell phones and tablet PCs.

Optimizing Rogers 4350B material performance for specific applications

- Structural Design

When designing circuits using Rogers 4350B material, proper microstrip and transmission line layout should be considered. Design engineers can optimize the width and spacing of microstrip or ribbon lines by accurately calculating impedance matching to reduce reflection loss and signal interference. Reasonable structural design can significantly improve the overall performance of the circuit and ensure smooth operation under high-frequency signal transmission conditions. - Adjustment of Material Parameters

Optimizing the dielectric constant and loss factor of Rogers 4350B is a critical step in improving its performance. Selecting the right material thickness for its application requirements helps to improve signal stability and transmission quality. For example, it is important to understand how the dielectric constant of a material changes at different frequencies so that you can make reasonable adjustments in your design to minimize the impact of frequency drift on system performance. - Optimization of manufacturing process

The physical properties of the Rogers 4350B material can be improved by using advanced manufacturing processes. For example, ensuring proper copper foil roughness can significantly improve conductivity and signal integrity. Strict control of manufacturing conditions, such as hot and cold working processes, can also minimize material loss during use and ensure high frequency performance. - Environmental Considerations

Rogers 4350B material performance is greatly affected by environmental conditions, so in practical applications should be considered in humidity, temperature and other factors on its electrical characteristics. Especially in high humidity environment, Rogers 4350B insulation resistance performance is excellent, can effectively reduce the leakage current. Appropriate selection or design of BOM (Bill of Materials) ensures that the final product has good stability and reliability in a specific environment.

As a high-performance polymer material, Rogers 4350B is highly acclaimed for its excellent electrical properties, mechanical strength and stability. It plays an important role in aerospace, automotive electronics, power electronics and communication devices, providing excellent support for a variety of demanding application scenarios. Whether it’s aerospace, where reliability is critical, or automotive electronics, where lightweighting is a must, Rogers 4350B delivers outstanding performance and stability.