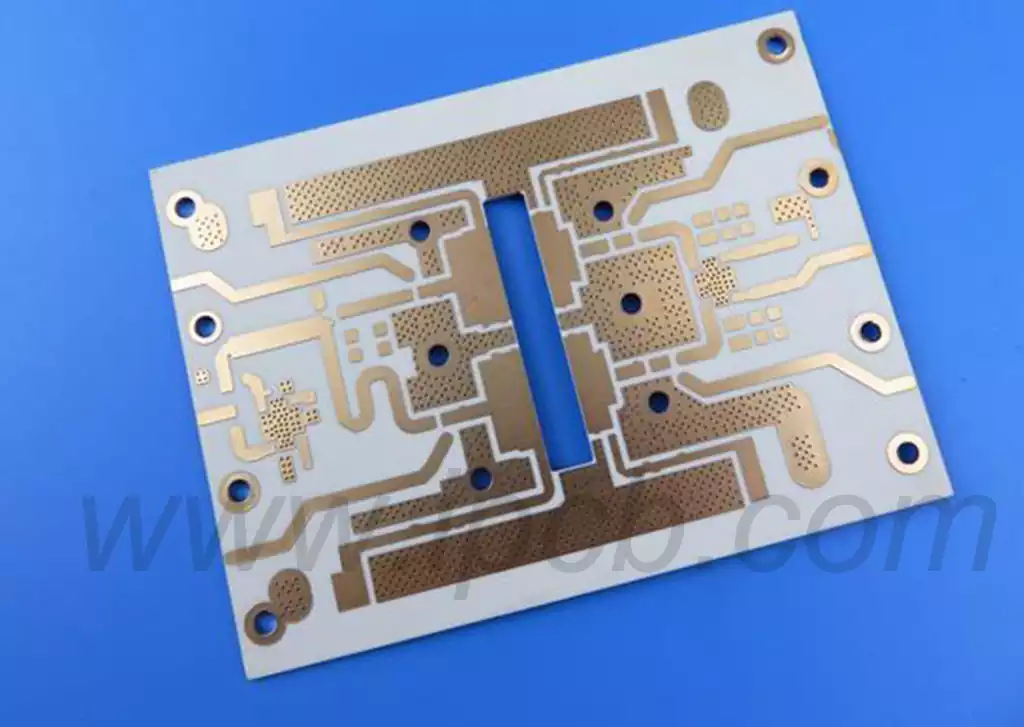

Rogers RO4003C substrate is known for its dielectric constant Dk of 3.38+/-0.05 and low dielectric loss Df of 0.0027 at 10 GHz. It is a unique glasscloth-reinforced, ceramic-filled hydrocarbon composite that combines the excellent electrical properties of PTFE/glasscloth with the superior processability of epoxy resin/glasscloth. processability.

RO4003C laminates are available in two different configurations with 1080 and 1674 glass cloth. All configurations have the same electrical performance specifications. RO4003C laminates are subjected to stringent process control, the material has a consistent dielectric constant (Dk) and low loss characteristics, and its unique mechanical properties allow it to be processed in the same way as a standard epoxy/glass process, at a much lower cost than traditional microwave laminates. Unlike PTFE microwave materials, this material requires no special through-hole processing or handling procedures.

Rogers RO4003C substrate Main Performance Parameters

Rogers RO4003C substrate is a high-frequency, high-performance circuit board material with several key performance parameters for RF and microwave circuit design. The following are its key performance parameters:

Electrical properties

Dielectric Constant (Dk): Typical value is about 3.38±0.05 (@10 GHz, process measurement), design value is about 3.55 (8~40 GHz range)

Dissipation Factor (TAN): Typical value about 0.0027 (@10 GHz)

Thermal Coefficient εr (temperature dependence of dielectric constant): Approx. 40 ppm/°C (-50°C to 150°C)

Thermal properties

Thermal conductivity: Typical value of about 0.71 W/m/°K (50°C)

Coefficient of Thermal Expansion (CTE):

X-direction: approx. 11 ppm/°C

Y direction: approx. 14 ppm/°C

Z direction (thickness direction): approx. 46 ppm/°C

Mechanical and Physical Properties

Density: approx. 1.8 g/cm³

Peel strength: approx. 6.0 lbs/in (35 µm copper thickness, ED foil)

Water absorption: approx. 0.04 % (48 hours, 50% humidity)

Flame Retardant Rating: Non-UL 94 V-0 rated (not flame retardant)

Key Benefits of Rogers RO4003C substrate

Excellent high frequency performance

Thanks to its low Dk and low Df characteristics, Rogers RO4003C substrate provides excellent signal integrity and transmission efficiency in high frequency and microwave applications.

High process compatibility

4003C materials are compatible with standard FR4 manufacturing processes, eliminating the need for special processing equipment and thus reducing manufacturing costs.

High Temperature Resistance

Electrical and mechanical properties remain stable in high temperature environments, making it particularly suitable for high power RF circuits and automotive electronics.

Good processability

Rogers RO4003C substrate is easy to drill and etch, and its machinability characteristics are superior to many PTFE substrates.

Wide Frequency Range Suitable

The material supports a wide frequency range from MHz to GHz, making it ideal for wireless communications and radar systems.

Typical application areas include:

Microstrip line and cellular base station antennas: enhancing communication quality and efficiency.

Automotive radar and sensors: Enhance the sensing capability of autonomous driving and intelligent vehicle systems.

Point-to-point microwave communications: Ensure the stability and security of high-speed data transmission.

Power amplifiers: optimise energy efficiency and signal amplification.

When using RO4003C material for circuit design, there are a number of key things to pay attention to. Rogers RO4003C substrate, as a high-performance microwave circuit material, has a dielectric constant (Dk) of 3.38 and a dielectric loss tangent (Df) of 0.0027. During the design process, you should make sure that the material’s electrical performance in the target frequency range meets the circuit requirements, and at the same time, reasonably select the thickness of the dielectric to achieve the control of signal propagation speed and accurate matching of impedance.

Compared with traditional FR-4 materials, Rogers RO4003C substrate has a better performance in terms of temperature stability, but still need to pay attention to the impact of temperature changes on its performance. Designs should consider the potential impact of temperature drift on component performance and the overall reliability of the circuit, especially in high-frequency application environments.

The Rogers RO4003C substrate is processed differently from conventional FR-4, and it is important to select a PCB manufacturer with the appropriate processing technology to ensure the accuracy of the cutting, etching and drilling processes to avoid signal attenuation or other performance degradation problems caused by process errors.