Screw terminal pcb refers to a component similar to an inductor that is made by directly drawing a coil on the pcb board with traces. Because this process has the characteristics of good voltage resistance, good consistency, flexible wiring, and strong current carrying capacity, it is widely used in the field of antennas. So how to make a fixed value inductor by this method?

Screw terminal pcb circuit board has good voltage resistance, and the AC voltage resistance can reach more than 3000V. The winding layout is highly flexible. Through flexible wiring and blind buried hole layout in the pcb board, multiple boards or multiple coils can be connected in series or in parallel to meet the design requirements. The copper thickness of the pcb board coil realized by iPCB thick copper technology can be made to 30Z to 120Z, which can achieve high current carrying performance that ordinary circuit board coils cannot achieve. By pressing the coil layer into the pcb board through pressing, it is possible to arrange multiple coils in a smaller volume space, improve power density, and reduce the volume of the transformer.

Antenna is an energy converter that converts the guided wave propagating on the transmission line into an electromagnetic wave propagating in an unbounded medium, or vice versa. The lower the frequency, the longer the wavelength, and the longer the antenna. Generally, antennas are reversible, that is, the same antenna can be used as both a transmitting antenna and a receiving antenna, and the basic characteristic parameters of the same antenna as a transmitter or a receiver are the same. For example, the antenna is used on a wireless device to transmit the electromagnetic wave signal output by the wireless device or transmit the electromagnetic wave signal received by the antenna back to the wireless device. The four aspects of antenna selection, matching, installation and debugging will affect the communication effect.

If the wireless communication device uses a pcb (printed circuit board) antenna, the production cost and time can be greatly reduced. The spiral antenna is integrated on the pcb in a microstrip form, which can greatly reduce the size. However, the rapid development of modern communications requires that the antenna can work in dual-frequency or even multi-frequency, so a dual-frequency pcb antenna is needed.

The technical problem to be solved by the present invention is to overcome the defect that the pcb antenna in the prior art cannot work in dual-frequency mode, and provide a dual-frequency screw terminal pcb antenna.

The solves the above technical problems through the following technical solutions:

A dual-frequency pcb spiral antenna, characterized in that it includes a pcb dielectric substrate, a spiral antenna, a matching short-circuited microstrip line and a metal ground, wherein the spiral antenna, the matching short-circuited microstrip line and the metal ground are all arranged on the pcb dielectric substrate, one end of the matching short-circuited microstrip line is connected to the metal ground, and the other end of the matching short-circuited microstrip line is connected to the spiral antenna, and the spiral antenna includes a front microstrip line arranged on the front of the pcb dielectric substrate and a back microstrip line arranged on the back of the pcb dielectric substrate, and the front microstrip line and the back microstrip line are connected through a metal via located on the pcb dielectric substrate.

Preferably, the spiral rotation direction of the front microstrip line is opposite to that of the back microstrip line.

Preferably, the front microstrip line is arranged as a plurality of parallel line segments on the front of the pcb dielectric substrate, and the back microstrip line is arranged as a plurality of parallel line segments on the back of the pcb dielectric substrate.

Preferably, the spacing between the multiple parallel line segments on the front side of the pcb dielectric substrate is 1mm-5mm, and/or, the spacing between the multiple parallel line segments on the back side of the pcb dielectric substrate is 1mm-5mm.

Preferably, the width of the spiral antenna is 0.5mm-1.5mm.

Preferably, the width of the matching short-circuit microstrip line is 0.5mm-1.5mm.

Preferably, the height of the metal via is 0.5mm-1.6mm.

Preferably, the angle between the spiral antenna and one side of the pcb dielectric substrate is 10° to 45°.

On the basis of conforming to the common sense in the field, the above-mentioned preferred conditions can be arbitrarily combined to obtain the preferred embodiments of the present invention.

The positive and progressive effect of the present invention is that the conventional antenna can resonate at 1/4 wavelength. For frequency bands such as RFID (radio frequency identification) and small base stations, the required resonance length is long and it is not easy to integrate into the pcb board. The spiral antenna is applied on the pcb dielectric substrate in the form of a wound microstrip line, which can greatly reduce the size. The spiral antenna is designed in an interlaced winding manner, which can excite two resonant modes, thereby forming a dual-frequency resonance. When the spiral antenna is integrated into the pcb circuit board, its height is reduced and the capacitance of the antenna is increased. In order to ensure the resonant characteristics of the antenna, a microstrip line is connected to the feeding end and the other end is connected to the ground. The short-circuited microstrip line can be equivalent to an inductor, thereby improving the matching of the input impedance.

The following is a specific embodiment and combined with the simulation results to further introduce the technical solution of the present invention.

(1) Dual-frequency pcb spiral antenna, the antenna is 22mm long and 5.5mm wide, the microstrip line width of the spiral antenna is 1mm, the microstrip line spacing is 3mm, the matching short-circuited microstrip line length is 5mm, and the line width is 1mm. The return loss simulation results are shown (obtained by electromagnetic simulation software HFSS, horizontal axis: frequency f (GHz), vertical axis return loss (dB)), the -6dB bandwidth is 904~934MHz, 1680~2170MHz respectively.

(2) Dual-frequency pcb spiral antenna, the antenna is 22mm long and 5.5mm wide. The microstrip line width of the spiral antenna is 1mm, the microstrip line spacing is 3mm, the matching short-circuit microstrip line length is 5mm, and the line width is 1mm. The simulation results of its gain pattern at a low frequency of 915MHz are shown in Figure 5, and it radiates symmetrical and good normal modes. Among them, the polar coordinate diagram of the total gain GainTotal changing with the rotation angle theta; Phi refers to the azimuth; Gaintotal is the total gain. The solid line represents GainTotal (Phi = 0°), and the dotted line represents GainTotal (Phi = 90°).

(3) Dual-frequency pcb spiral antenna, the antenna is 22mm long and 5.5mm wide, the microstrip line width is 1mm, the microstrip line spacing is 3mm, the matching short-circuit microstrip line length is 5mm, and the line width is 1mm. Its gain pattern simulation at a high frequency of 1900MHz also radiates symmetrical and good normal modes. The solid line represents GainTotal (Phi = 0°), and the dotted line represents GainTotal (Phi = 90°).

Compared with the existing dual-band antenna, the present invention has small size, low cost, high efficiency, easy integration and simple processing.

Screw terminal pcb is a commonly used wiring method in pcb design, which has many advantages and application scenarios. So what is the pcb spiral wire like?

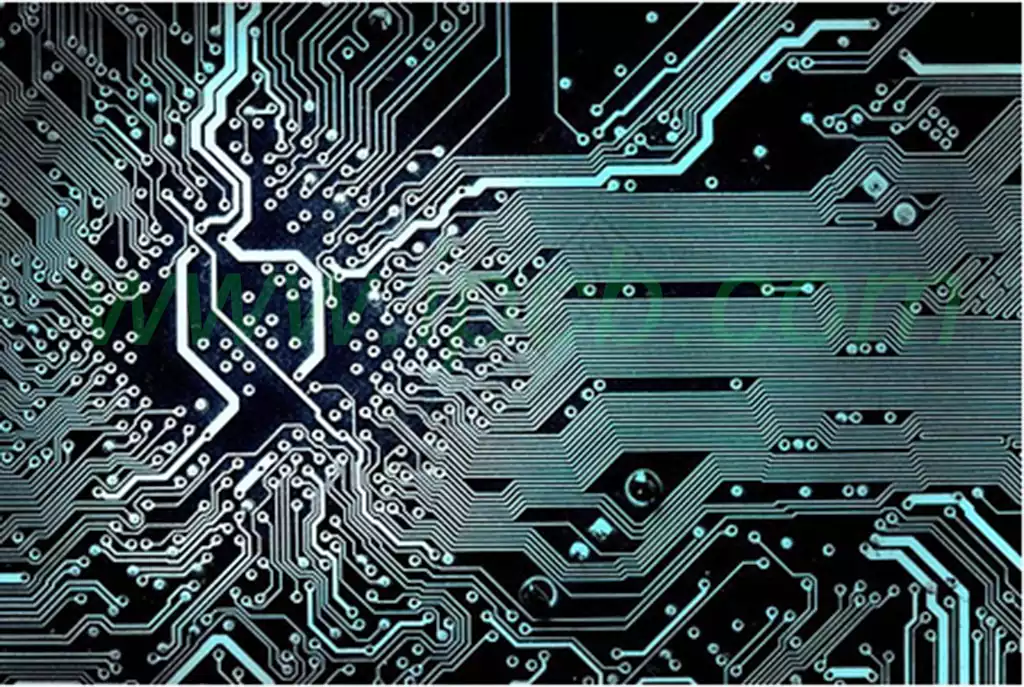

pcb spiral wire is a spiral wiring method, which is usually used to connect different circuit components or modules. Compared with traditional straight wiring, spiral wire can provide better electromagnetic compatibility (EMC) performance and reduce signal interference and noise.

Screw terminal pcb is a spiral wire structure designed on a pcb circuit board. This design is usually used in high-frequency circuits, which can reduce interference and loss during signal transmission and improve signal quality and stability. Spiral routing can effectively reduce electromagnetic radiation, crosstalk and backflow problems, so that the circuit board has better anti-interference performance.

Advantages of pcb spiral wire

- Improved EMC performance: The curved shape of the spiral wire can effectively reduce the radiation of magnetic and electric fields and reduce the possibility of electromagnetic interference.

- Reduce inductance: Through the layout of the spiral wire, the inductance of the line can be reduced, and the speed and stability of signal transmission can be improved.

- Save space: The spiral wire can achieve a longer wiring length in a limited pcb space, thereby saving space.

- Flexibility: The spiral wire can be flexibly adjusted and optimized according to actual needs to adapt to different circuit design requirements.

Disadvantages of pcb spiral routing - Increased complexity: The spiral routing design is relatively complex and requires more design and analysis work.

- Manufacturing difficulty: The manufacturing process may be more complicated and require higher technical requirements. 3. Cost: Compared with traditional routing design, spiral routing may increase manufacturing costs.

Key points of pcb spiral wire design - Line width and spacing: According to the requirements of the circuit, select the appropriate line width and spacing to ensure sufficient current carrying capacity and signal isolation.

- Number of layers and stacking structure: Consider the number of layers and stacking structure of the pcb, and arrange the position and direction of the spiral line reasonably to avoid cross interference with other signal lines.

- Grounding and shielding: Provide good grounding and shielding measures to enhance EMC performance and reduce noise interference.

- Wiring rules and constraints: Follow the wiring rules and constraints of pcb design to ensure that the layout of the spiral line meets the design specifications and process requirements.

With the continuous development of electronic technology, the requirements for pcb design are getting higher and higher. In the future, the design and manufacture of screw terminal pcbs will be more refined and intelligent to meet the needs of high-performance electronic devices. At the same time, the application of new materials and processes will also promote the development and innovation of pcb spiral lines. We at iPCB provide customized free will to our customers. There are many reasons why you choose this option, including excellent stability and improving the overall performance of the device to its maximum potential.

iPCB provides the most reliable customization service in the pcb industry. In the customized screw terminal pcb, you can choose double coils, single coils, and other features you may want to add to improve the performance of the circuit board.