Semiconductor IC design (Integrated Circuit Design) refers to the design process of integrating multiple devices and functional modules on a wafer and connecting and interconnecting them efficiently based on semiconductor processes and in accordance with certain circuit design rules and principles. Typically, semiconductor IC design involves a number of sub-fields,including digital circuit logic design.Analogue circuit design. RF IC design. Power management and processor design.

In semiconductor IC design, designers need to use computer-aided design tools for circuit design. Simulation. Layout validation and verification. At the same time, they need to follow a series of design specifications and circuit standards,for specific application scenarios, using the best design methodology and strategy to meet the design requirements and complete the design within the specified time.

The production process of semiconductor products covers the three core stages of design,manufacturing and packaging and testing. Manufacturing and packaging and testing of the three core stages.

1.Integrated circuit (IC) design: this process is the system.Logic and performance of the design requirements into a specific physical layout of the key steps, including logic design (also known as front-end design).Circuit design and graphic design (these two parts belong to the back-end design, i.e., physical design category). Designers use automated design software, EDA, and some designs may incorporate licensed IP cores.Once the design is complete,these circuit diagrams are converted into photomasks in preparation for the next stage of manufacturing.It is worth noting that the design process relies heavily on computers to complete, so there is relatively little need for hardware equipment.

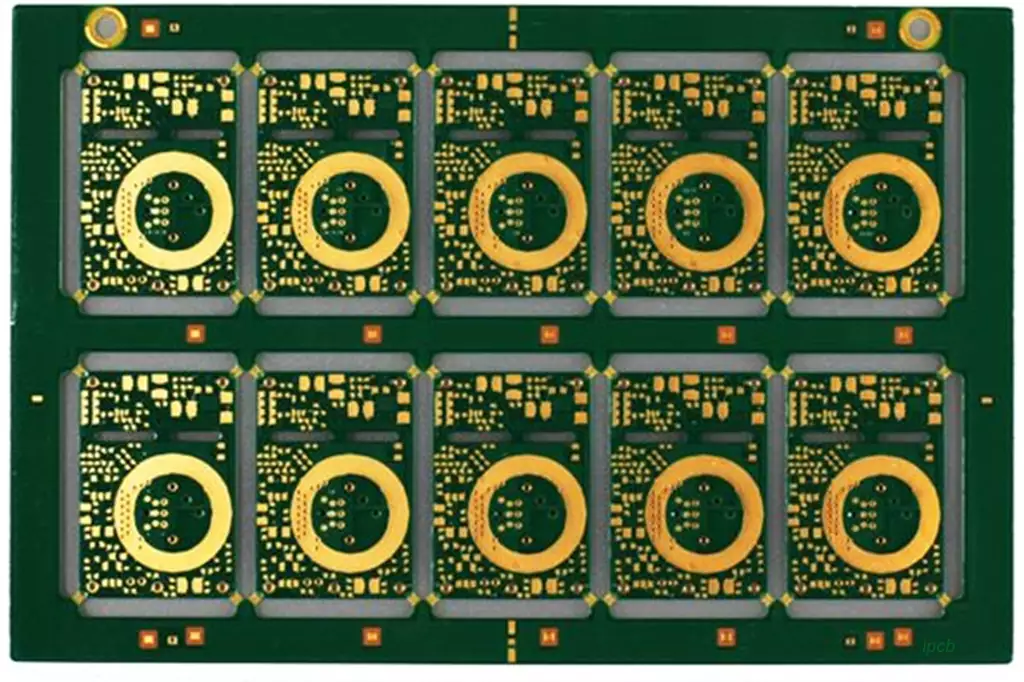

2.IC manufacturing: the manufacturing stage can be subdivided into two parts: wafer manufacturing and wafer processing. Wafer manufacturing refers to the use of silicon dioxide raw materials,after a series of processes,such as silicon purification. Polysilicon manufacturing. Pull crystal. Cutting and grinding, etc., and ultimately produced a single crystal silicon wafer process.This process will use the melting furnace, CVD equipment. Single crystal furnace and slicer and other equipment. Wafer processing is in the wafer material has been prepared to build a complete integrated circuit chip, including coating. Photolithography. Etching. Ion implantation and other core process steps. This link is the wafer for further processing to meet specific product requirements.

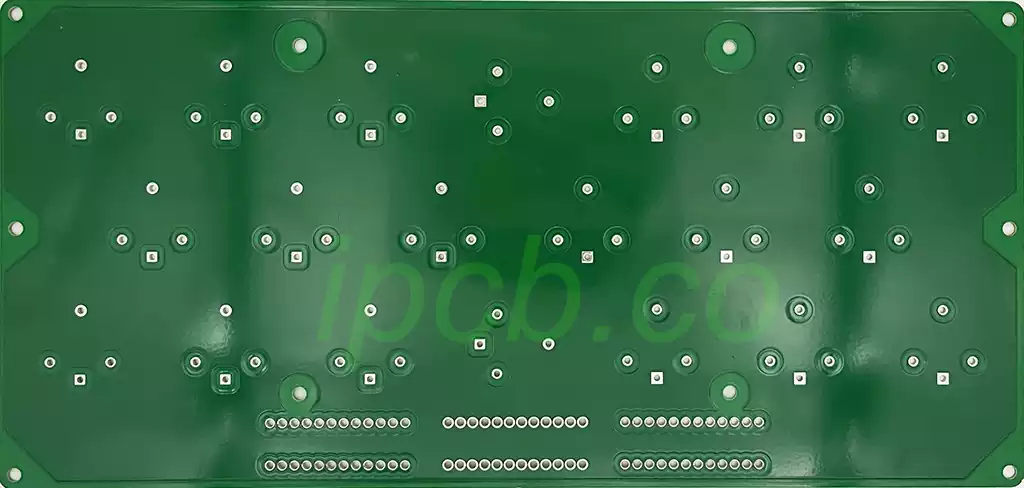

3.IC packaging and testing: as the last step in the production process of semiconductor equipment, packaging link mainly includes thinning / cutting. Mounting / interconnection.Packaging and testing steps.These steps require the use of cutting and thinning equipment. Leader. Bonding machine and sorting test machine and other equipment.The purpose of encapsulation is to concentrate the semiconductor material modules in a protective shell to prevent physical damage or chemical corrosion.After completing the packaging, the product will be tested, and only products that pass the test will be put into downstream applications as final products.

The core tasks of IC board design:

- Function definition: based on market demand. Based on market demand, technology evolution and specific application scenarios, the core functions and characteristics of the chip are defined, such as processor rate. Storage capacity. Signal processing performance, etc.

- Circuit design: planning the internal circuits and components of the chip, with the help of EDA (Electronic Design Automation) tools to implement circuit diagram design and simulation, covering digital circuits. Analogue circuits. Mixed-signal circuits and RF circuits.

- Physical Layout: Translate chip-level and gate logic into physical structures, including layout. Mask production and final layout design and other steps.

- Verification and Testing: Implement verification and testing of the chip to ensure that it meets the design standards and specifications, as well as reliability testing and quality control before mass production.

- Documentation: Write design documents covering functional requirements. Technical specifications. Design flow. Test plan. Simulation results, etc.

IC board design is an esoteric and continuous learning technology,requiring a solid foundation in electronic circuits. Excellent EDA tool operation skills, as well as the ability to analyse market demand and forecast technology trends.At the same time, also need to have a keen insight into emerging technologies and rapid response capability.Apply advanced EDA tools and techniques for chip design and verification, explore and develop new chip architectures and features to meet market demands and enhance product competitiveness.

Difference between IC board design and chip design:

In general, the terms IC board design and chip design can be considered synonymous in most cases, but they may have certain subtle differences in specific contexts.

IC design focuses on the comprehensive design of the entire integrated circuit chip, covering circuit design.Signal processing. Logic control and other aspects. It aims to integrate multiple electronic components and circuits on a single chip to achieve a high degree of integration and complex functionality.In addition, IC design also needs to consider the chip manufacturing process.Physical structure. The electrical connections between functional modules,as well as factors to ensure the overall reliability and performance of the chip.

Chip design, on the other hand, focuses on the specific design and implementation of the internal circuitry of the chip,involving mathematical methods. Algorithm. Circuit networks and other parts of the design, and usually for specific industrial electronics market areas.Chip design aims to use digital and analogue integration techniques to implement circuits and systems with specific functions and to optimise circuit parameters and performance to meet specific market requirements.

Therefore, it can be said that IC board design and chip design are related to each other, but they have different application scenarios and focuses when it comes to specific applications. In the field of industrial electronics, chip design is usually combined with circuit board design. System integration and other projects are combined to form a complete hardware solution. IC design focuses more on the high degree of integration of the chip and the implementation of complex functions, requiring chip designers to have the technology. It requires chip designers to have the comprehensive ability of technical, market and product knowledge to continuously promote the innovation and development of integrated circuits.