SMT stencil is SMT-specific molds whose main function is to aid in the deposition of solder paste, to transfer the exact amount of paste to the exact location on an empty PCB.

Stainless steel mesh was initially made of wire mesh, then due to its durability, iron wire mesh, copper wire mesh, and finally stainless steel wire mesh appeared. But no matter what material the wire mesh is made of, it has the disadvantages of bad molding and low precision. With the development of SMT, the requirement of stencils increased, and stainless steel wire mesh came into being.

The types of SMT stencil templates can be categorized according to the fabrication process, accuracy of the opening position, and smoothness of the opening hole wall. The following are some common classifications:

Laser stencil: the use of data file production, reducing the production error link, opening position accuracy is very high, the whole error ≤ ± 4μm, its opening has a geometric pattern, which is conducive to the printing of solder paste molding.

Laser stencil template: This is the most commonly used template in the industry, which is characterized by the direct use of data files to produce, reducing the production error link.

Electropolishing stencil: After laser cutting, the stencil is post-treated by electrochemical methods to improve the opening hole wall. The advantage is that the hole wall is smooth, especially suitable for ultra-fine pitch QFP/BGA/CSP, reducing the number of times is wiped, and greatly improving work efficiency.

Microporous stencil: This stencil is suitable for UV oil printing on resistive screens, cell phone protective film, and isolation points in cell phone protective covers.

Dual process dual process stencil: this stencil is tin paste stencil and red glue at the same time in a network, this process is slightly more complex, there is this process is more difficult for the factory.

Red adhesive stencil: patch adhesive, also known as SMT adhesive, SMT red adhesive, is a red paste evenly distributed in the hardener, pigment, solvents, and other adhesives, mainly used to fix the components on the printed board, usually dispensed by dispensing or stencil printing. Then the patch is applied.

Silver paste stencil: This stencil production process and use of methods similar to the solder paste stencil, but because of the characteristics of the silver paste itself, so in the design of the silver paste stencil is not the same as the solder paste stencil.

In addition, according to the board structure of small, dense pad characteristics, such as COB, binding IC, etc. The advantages are for small pads, close spacing will not make it easy to connect the tin, and the disadvantage is that the cost is higher.

The advantages of SMT stencil mainly include:

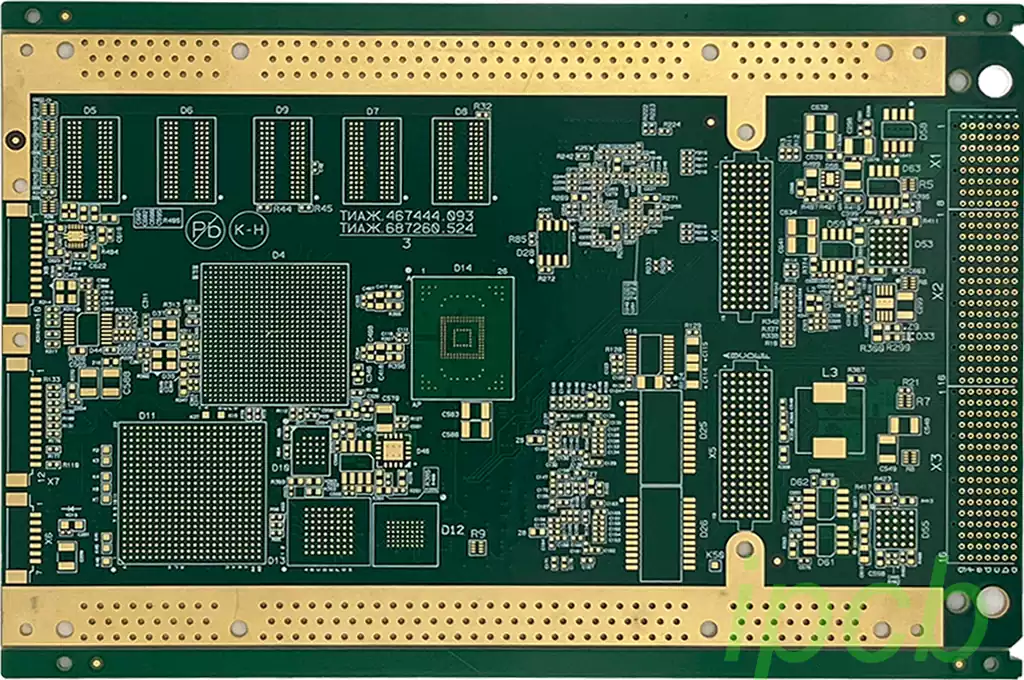

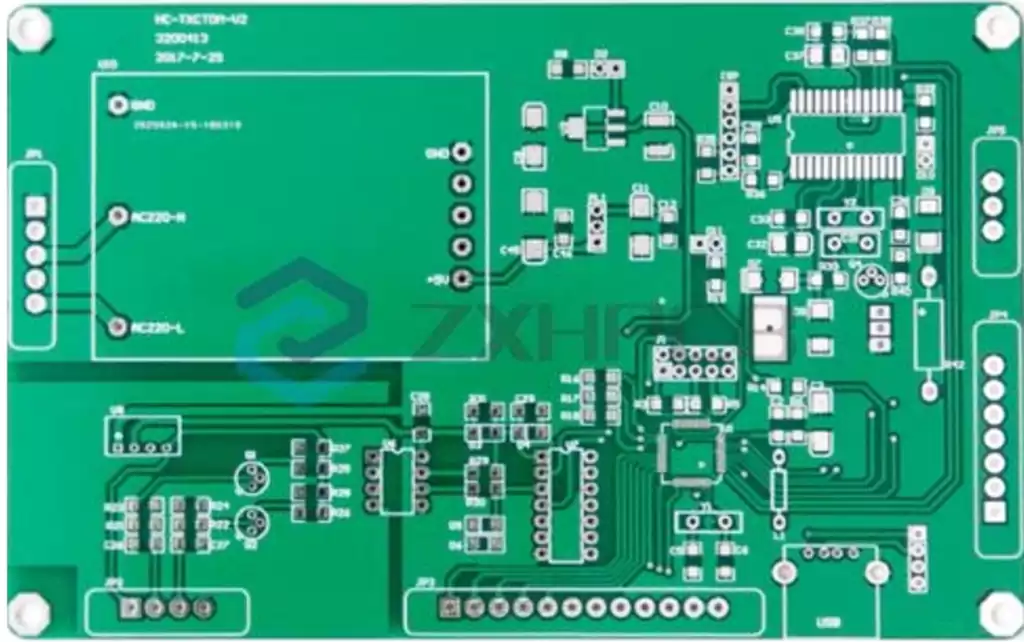

Strong flexibility: compared with traditional printing methods, the use of it to print circuits can be more controllable. the SMT stencil printing production process, you can choose the number of printing sections and printing position, layout design, lacquer thickness, and other factors, to realize the diversified custom production of circuit boards.

High production efficiency: have very high production efficiency during the manufacturing process. Its high-precision pad-type cover structure and excellent material make it have excellent durability and enable fast and accurate manufacturing of large-scale circuit boards.

Low production cost: use relatively low material costs in the manufacturing process. Moreover, due to its high-precision printing effect and fast production speed, it can significantly reduce the production cost of circuit boards.

Stable and reliable quality: The development of it technology has made it a high-precision printing technology, and the stable and reliable quality of the circuit boards it produces can meet the complexity and diversity of high-end applications, so it is widely used in various fields of the electronic circuit board manufacturing industry.

Good Reliability: Circuit boards made from SMT stencils are characterized by excellent reliability in terms of material uniformity, printing accuracy, and thickness of the lacquer layer, which ensures that the circuit boards are of good quality and stable performance.

However, SMT stencils also have some disadvantages:

Complicated production process: The production process is relatively complicated and requires several steps, including cutting, cleaning, polishing, etc.. All these steps need to be strictly controlled, otherwise the quality and life of the stencil may be affected.

Higher cost: Although the use of templates can improve productivity and product quality, its production cost is high, which may be less economical for small batch production.

Limited scope of application: mainly used for soldering surface mount components, and may not be suitable for other types of components or situations that require other soldering methods.

SMT stencil plays a vital role in electronics manufacturing. Despite some limitations, its advantages can be fully utilized to improve soldering quality and productivity through reasonable use and maintenance.