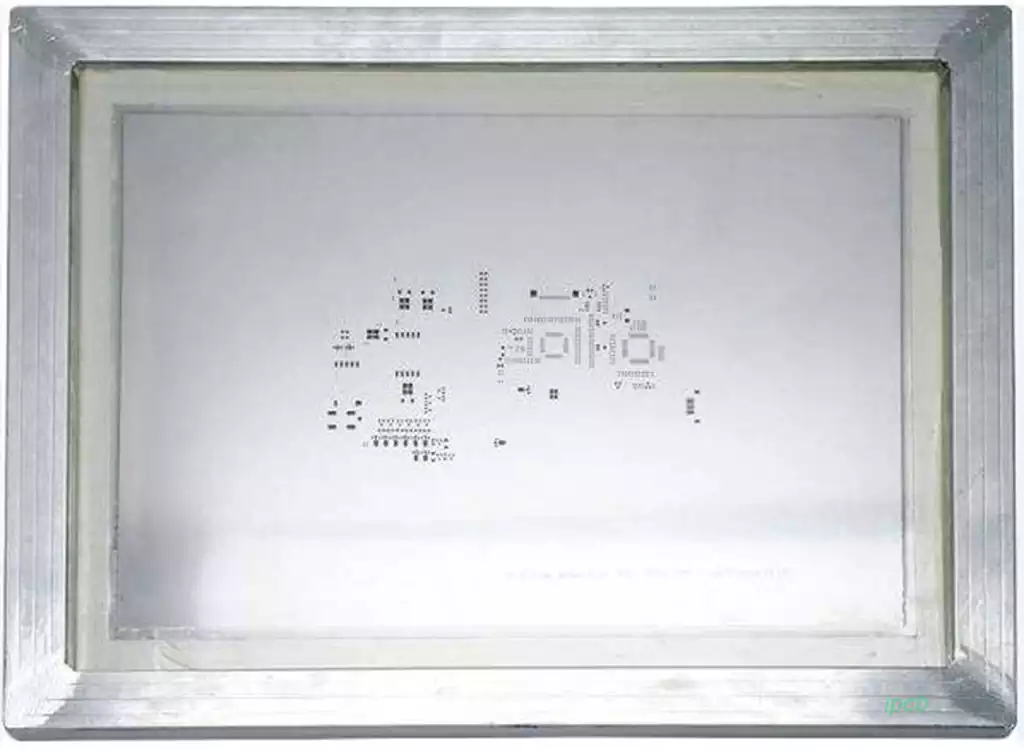

A stencil circuit board, also known as an SMT stencil, is an essential tool in the printed circuit board (PCB) manufacturing process. It is a metal mesh used in PCB production to help position and protect components on the PCB board, as well as to ensure the accuracy and quality of the board during processing.

PCB stencils usually use stainless steel or nickel alloys as materials. These materials are highly resistant to abrasion, corrosion and stability, and are able to withstand the stresses and chemicals used in PCB manufacturing. pcb stencils are made of fine wire threads woven together to form a grid structure. The density and aperture of the wire mesh depends on the requirements of the solder paste or solder paste and the spacing of the component pins.

PCB stencils are useful in two main areas: line control and solder control. For line control, the shape and size of the PCB stencil matches the lines on the board, which can control the width, spacing and shape of the lines to ensure the accuracy and stability of the lines. For soldering control, the holes on the P stencil can control the position and shape of solder paste and solder to avoid short circuits and poor soldering.

Classification

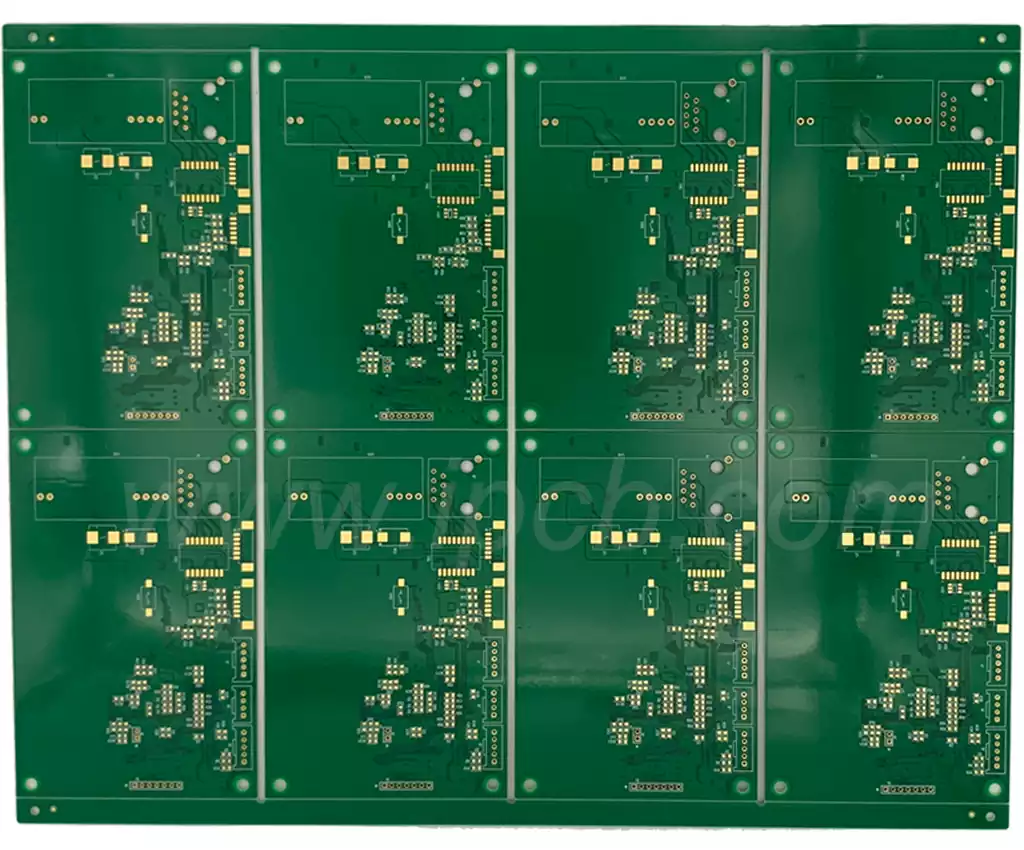

Frame type stencil: Frame type stencil consists of a frame and a mesh, the frame is usually made of aluminum alloy or steel, and the mesh is a mesh structure made of stainless steel. This type of stencil is suitable for PCB boards of various sizes, easy to use and easy to replace.

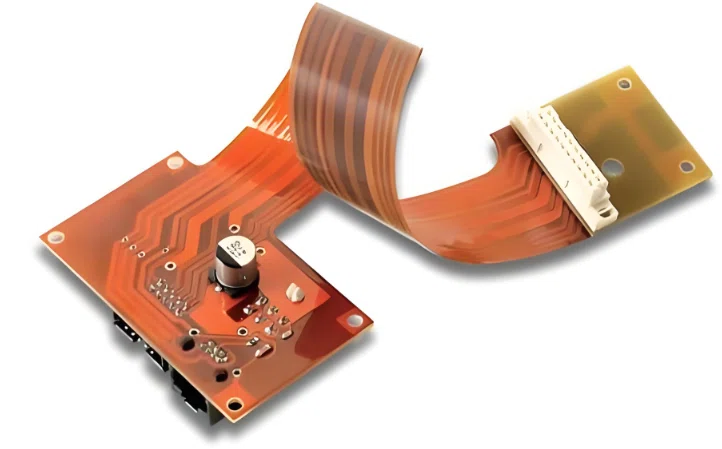

Clamping stencil: Clamping stencil is a kind of stencil without frame, it is directly clamped on the PCB board for printing operations. This stencil is suitable for the production of small PCB boards, with low cost, short production cycle and other advantages.

Step Stencil: Step stencils are a type of stencil with different thicknesses and aperture ratios, which are suitable for the printing needs of electronic components of different heights and densities. This stencil can be adjusted and optimized according to the specific layout of electronic components to improve printing quality and efficiency.

Electroplated Diamond Stencils: Electroplated diamond stencils are diamond coated stencils with excellent abrasion resistance and service life. This stencil is suitable for high-precision, high-density electronic components printing needs, can effectively improve the printing quality and stability.

When selecting PCB stencils, the following principles need to be considered:

Suitability: Ensure that the selected stencil’s parameters such as size, aperture ratio and thickness match the requirements of the PCB board and electronic components.

Accuracy: Choose a stencil with high precision to ensure that the solder paste or red glue can be accurately printed onto the pads of the PCB substrate.

Durability: Select stencils with good abrasion resistance and long service life to reduce production costs and improve productivity.

Cost: Under the premise of meeting the adaptability, accuracy and durability, try to choose the stencil with lower cost.

Factors affecting the cost

Material: Stencils are usually made of stainless steel or nickel alloy, and the cost will vary from material to material. Generally, nickel alloy will cost more than stainless steel.

Thickness: The thickness of the stencil will also affect its cost. Thicker stencils provide better support and durability, but will also increase the cost of the material.

Aperture Diameter and Hole Spacing: The aperture diameter and hole spacing on a stencil is based on the pads on the PCB. The smaller the aperture and the denser the hole spacing, the more difficult it is to manufacture and therefore the cost will increase accordingly.

Stencil size: The larger the size of the stencil, the more material is required and the more difficult it may be to manufacture, thus leading to an increase in cost.

Processing Accuracy: Higher precision stencil manufacturing requires more advanced equipment and processes, so the cost will increase accordingly.

Customization needs: If the customer’s project has special customization needs, such as shaped holes, markings, etc., it will also increase the manufacturing cost of the stencil.

Supplier Differences: Different suppliers have differences in manufacturing process, equipment investment, labor cost, etc., so the quoted price will be different.

Stencil circuit board is an important tool to guarantee the quality of circuit boards, and its correct use can ensure the pcb board’s line precision and soldering quality. Choosing the right material and thickness, keeping it clean and flat, as well as reasonable storage and maintenance are all important steps to ensure that the PCB stencil works properly.