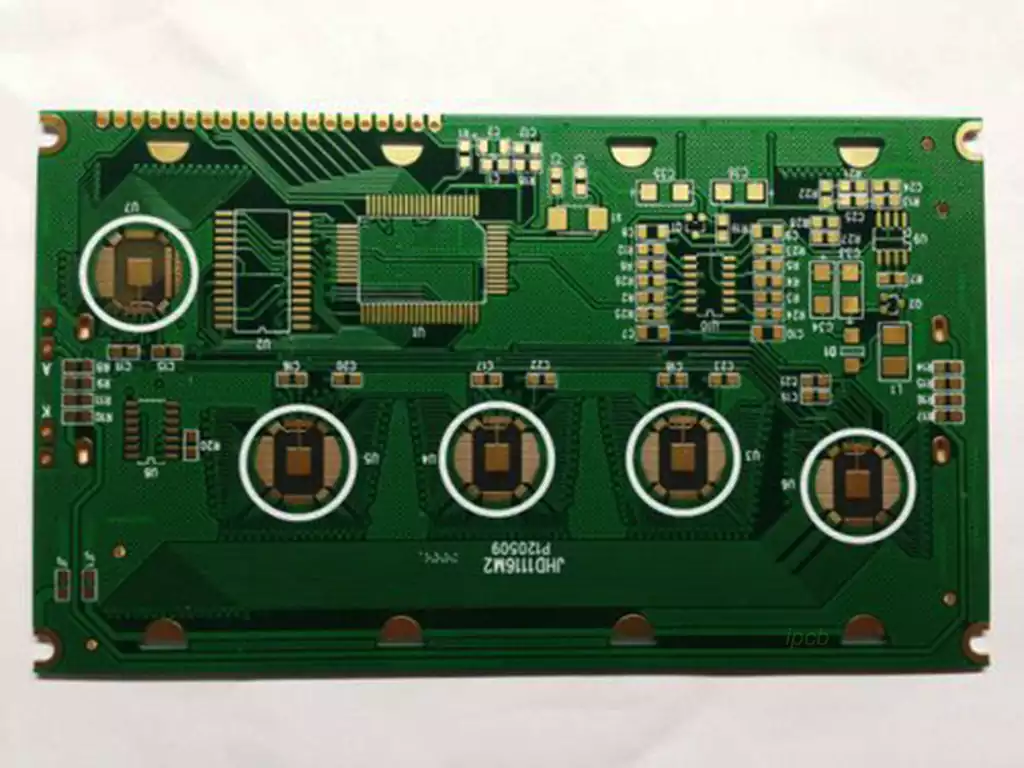

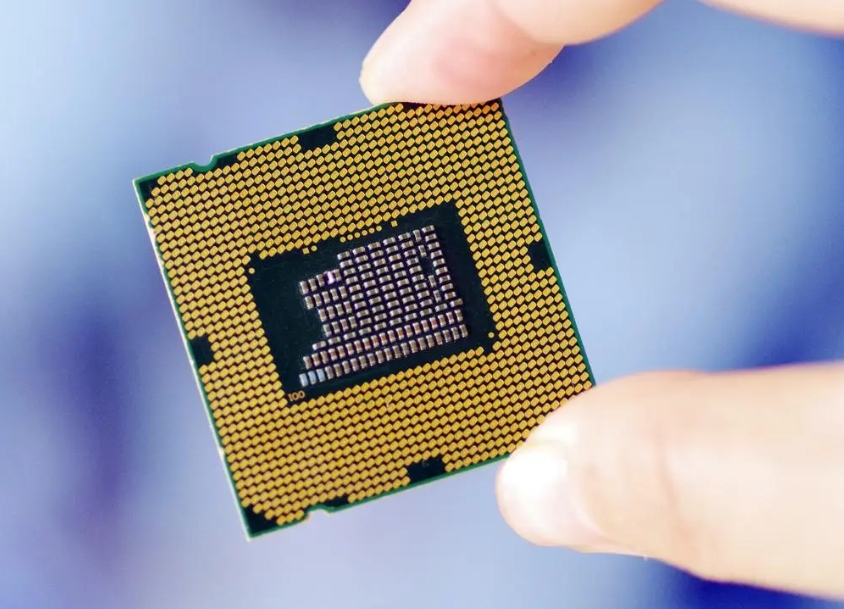

What is a substrate in semiconductor?A semiconductor substrate is a key material used in the manufacture of integrated circuits. It is usually made of monocrystalline silicon and is characterized by high purity and absence of impurities. The surface of the substrate is coated with a layer of photoresist to create graphics by photolithography. Oxide and silicon films are grown layer by layer on the substrate to form the insulating layer in the circuit and devices such as transistors. Eventually, unwanted parts are removed by etching technology to form the final integrated circuit. The manufacturing of substrates is an important part of integrated circuit manufacturing and plays a vital role in the development of the electronics industry.

Common semiconductor chip substrate materials other than silicon include sapphire, silicon nitride, silicon carbide and other materials.

Silicon Substrate

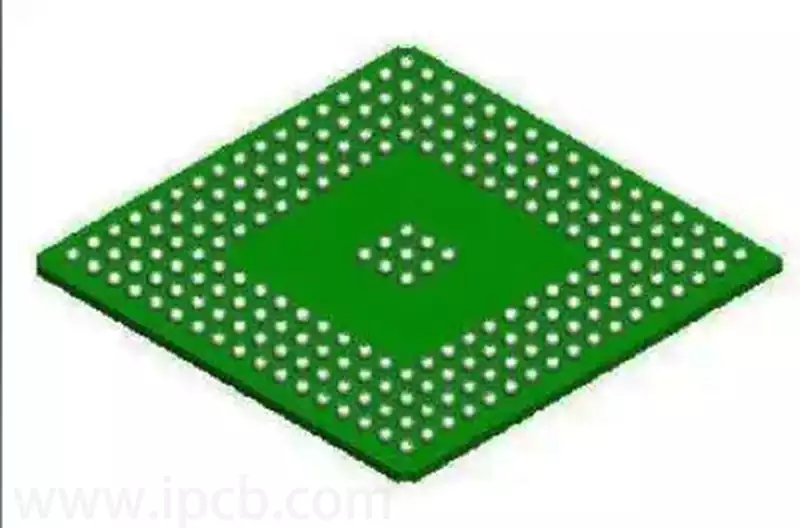

Silicon wafers are the dominant material in the semiconductor industry, accounting for about 90% of the global market. Silicon has many advantages, such as low cost, good stability, and easy processing and manufacturing. Silicon also has good electrical properties. The fabrication of silicon chips is a multi-step process that involves steps such as doping, thin film growth, and preparation.

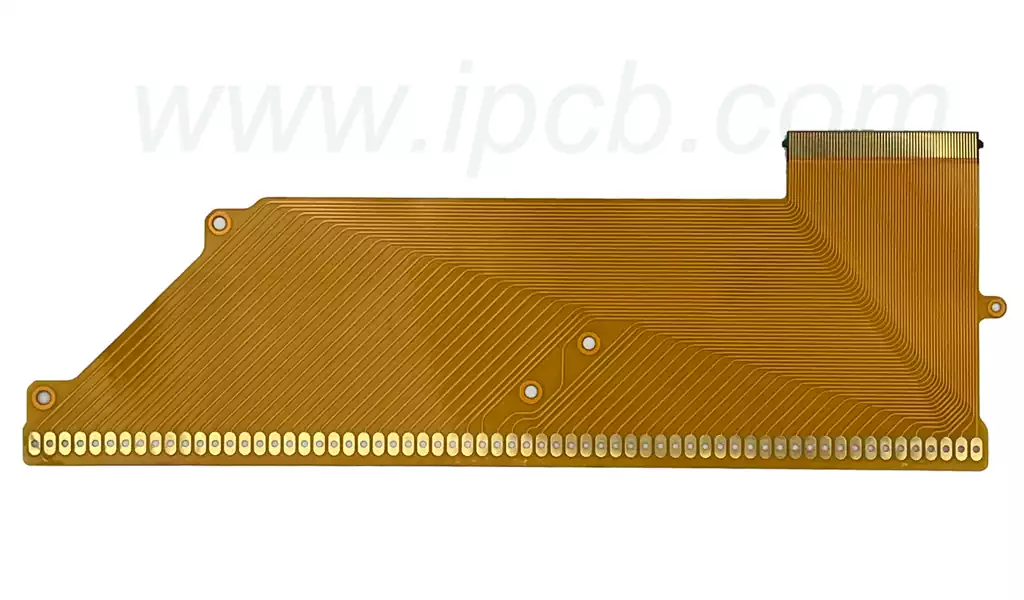

Sapphire Substrate

Sapphire substrate is a high quality material with excellent thermal stability and electrical properties. Sapphire substrates are used in the manufacture of LEDs, laser diodes, power devices, and more.

Silicon Nitride Substrate

Silicon nitride substrate is a new type of substrate material with excellent electrical properties, thermal stability and chemical stability. It is widely used in the manufacture of high power, high frequency and high temperature devices.

Silicon Carbide Substrates

Silicon carbide substrates are used in the manufacture of high frequency and high power electronic devices. It has excellent thermal stability, mechanical strength and chemical stability.

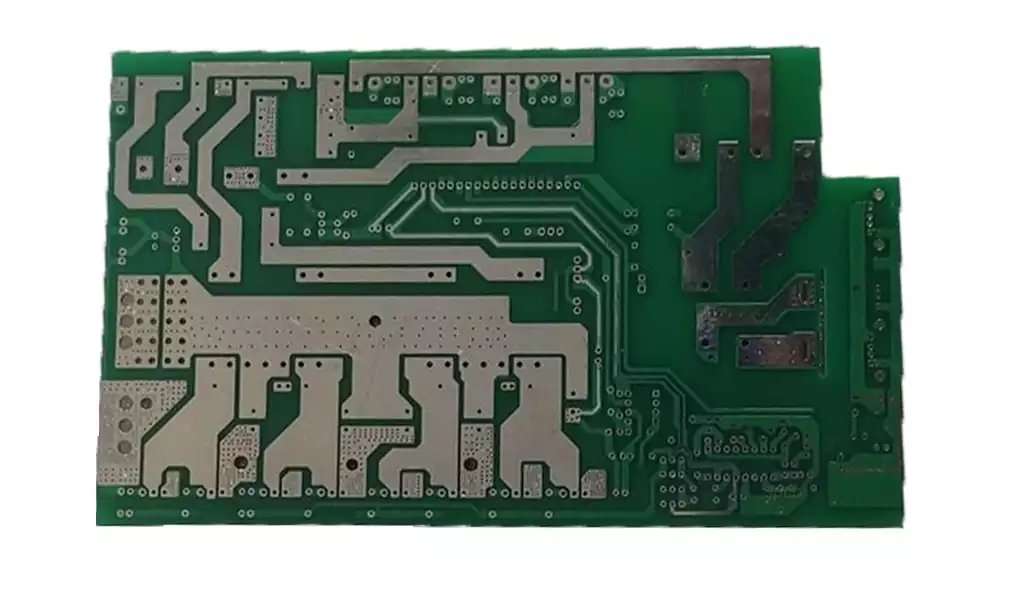

Substrate in semiconductor Material Selection

The selection of semiconductor substrate materials is critical for epitaxial growth and device performance and requires consideration of several factors. The following are the main factors to consider when selecting a substrate material.

Structural properties: The crystal structure of the substrate material needs to be the same or similar to that of the epitaxial material in order to obtain a high quality epitaxial layer. At the same time, the lattice constant of the substrate material should match that of the epitaxial material to minimize the stress caused by lattice mismatch and avoid defects.

Chemical stability: The substrate material should have good chemical stability to ensure that it will not be decomposed or corroded at high temperatures and in the presence of gas-phase organic sources. In addition, chemical reactions between the substrate material and the epitaxial material should be avoided to maintain the purity of the epitaxial layer.

Thermal properties: The thermal conductivity of the substrate material should be high to effectively transfer heat out and reduce the thermal stress of the epitaxial layer. At the same time, the coefficient of thermal expansion between the substrate material and the epitaxial material should be similar to reduce the stress caused by the difference in the coefficient of thermal expansion.

Conductivity: The substrate material should have good conductivity in order to achieve efficient current transfer on the epitaxial layer. For some special applications, such as photovoltaic devices, the substrate material should also have a low light absorption coefficient, in order to help improve the light extraction efficiency and luminous efficiency of the device.

Mechanical properties: the substrate material should have excellent mechanical properties, easy to cut, thinning, polishing and other processing operations. In addition, the hardness, toughness and other mechanical properties of the substrate material will also affect the growth quality of the epitaxial layer and device performance.

Cost and size: the cost of the substrate material should be inexpensive, in order to achieve mass production and reduce device costs. At the same time, the size of the substrate material should be large enough to meet the needs of mass production.

Role of Semiconductor Substrates

- Improve the performance of semiconductor devices

Substrates are generally characterized by good crystal structure, low defect density and small surface roughness. These excellent physical properties help to improve the performance of semiconductor devices, such as improving carrier mobility, reducing the sleep current, etc.. - Ensure the stability of semiconductor devices

The substrate can provide a crystal structure and precise lattice orientation that matches the chip size, which helps to improve the stability and reliability of the device. At the same time, the substrate can also effectively prevent mechanical stress and lattice mismatch and other problems. - Influence the performance and process parameters of semiconductor devices

The choice and nature of substrate materials have a great impact on the performance and process parameters of semiconductor devices. For example, silicon substrates are commonly used to fabricate CMOS devices, while silicon nitride substrates are suitable for the preparation of GaN-type devices and so on.

In the rapid development of semiconductor technology, the selection and characterization of substrate in semiconductor materials are critical to device performance. As materials science advances, diverse substrates will continue to emerge to meet the needs of increasingly complex and high-performance electronic devices, driving technology forward.