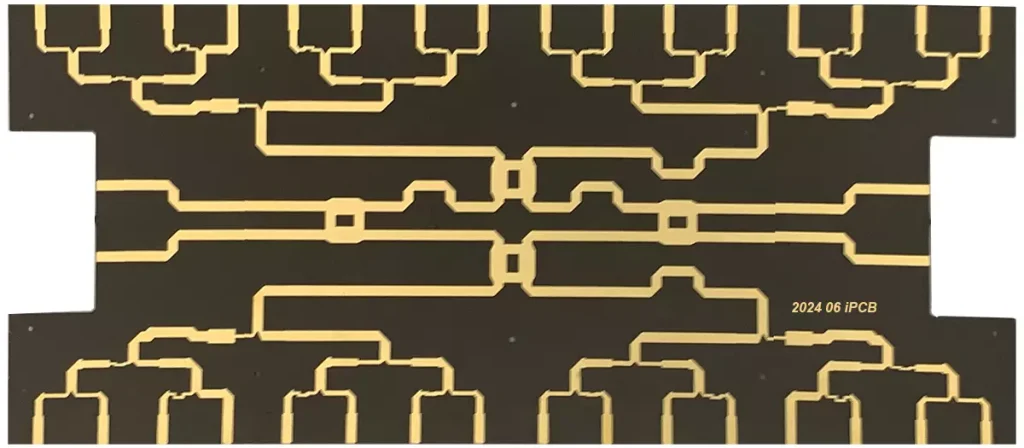

Taconic PCB, known in Chinese as Taikangli, is one of the specialty PCB circuit board sheets, originally produced in the United States. It has the characteristics of lighter weight, good waterproof and fireproof performance, higher heat resistance and strength, and non-adhesion. As a kind of high-frequency and high-speed board, Taconic PCB has a wide range of dielectric constant values, which can reach from 2.10 to 10.0, with relatively low dielectric loss, so it is widely used in antenna field.

Taconic PCB is finely manufactured with strong mechanical strength and reliable fabrication to meet the needs of a wide variety of applications. It is available in a variety of different types of boards, such as TLX series, TLY series, LCAM series, RF series, etc. Each series has different characteristics and parameters, and therefore the usage will be different.

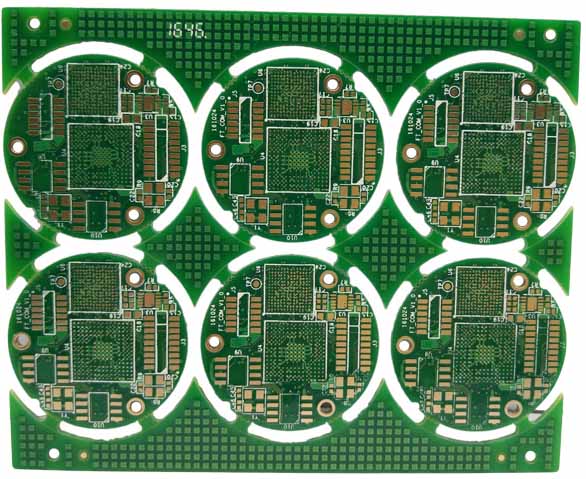

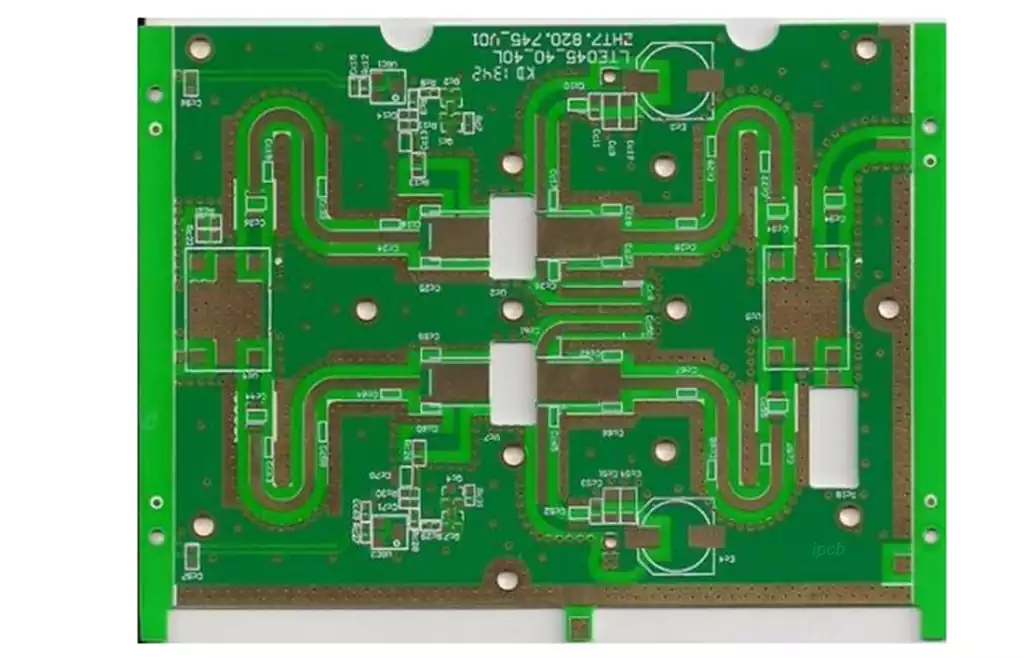

IPCB’s Taconic PCB Manufacturing Capabilities.

Number of Layers: 1-48

Minimum Line Width/Pitch: 3mil (0.075mm)

Minimum Hole Diameter: 4mil (0.1mm)

Board Thickness: 0.1mm~6.0mm

Maximum board size: 2031.5(500mm800mm)

Material: Taconic PCB Prototype Full Series

Double-sided Taconic PCB samples are due in 3 days delayed and can be delivered in as little as 24 hours.

4-layer Taconic PCB samples are due in 6 days and can be delivered in as little as 48 hours.

6 Layer Taconic PCB samples are delivered in 7 days and as fast as 72 hours.

Taconic PCB 8-layer to 10-layer samples have a lead time of 9 days and can be delivered in as little as 96 hours.

Advantages of Taconic PCB Laminate Materials

The use of high-quality substrates and materials ensures the stability and reliability of PCB laminates. The materials have low dielectric constants and low coefficients of thermal expansion to minimize losses and delays in signal transmission.

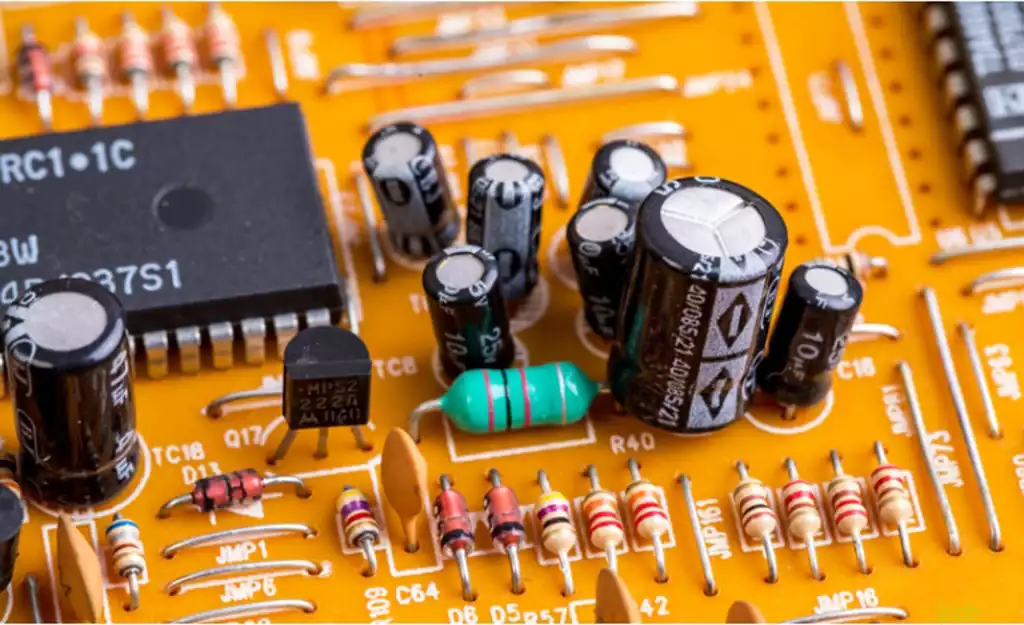

Taconic PCB laminate materials have excellent heat resistance and can maintain stable performance in high-temperature environments. This enables PCBs to maintain their electrical reliability in various harsh operating environments.

Tycolite PCB laminate materials have great mechanical strength and can maintain structural integrity in vibration and shock environments. This provides more reliable support for electronic devices and ensures their stable operation.

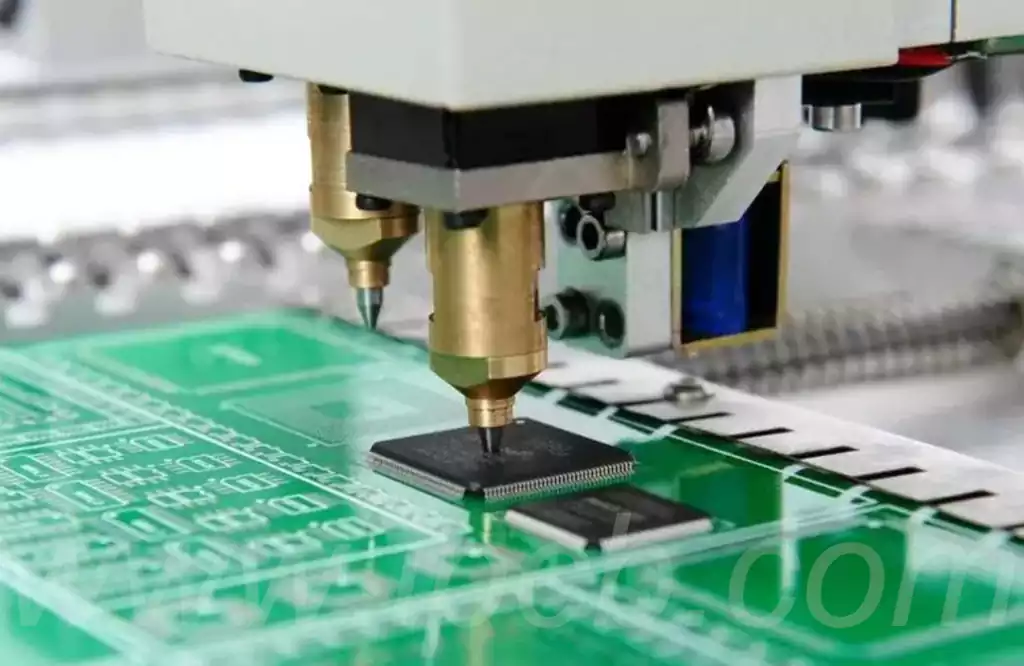

The use of advanced manufacturing processes ensures the flatness and precision of PCB laminates. Its fine machining process results in clear circuit graphics and precise lead-through holes, which further improves the reliability of the PCB board.

Application areas of Taconic PCB materials

With its excellent performance and reliability, PCB laminate materials are widely used in communication, aerospace, medical electronics, and other fields. In the field of communication, they are used to manufacture key components in communication equipment, such as routers, switches, and base stations. In aerospace, its high reliability and heat resistance make it ideal for flight control and satellite communication systems. In medical electronics, it is widely used in the manufacture of medical equipment such as pacemakers and monitors, providing a reliable guarantee for the normal operation of medical equipment.

Taconic pcb has excellent performance and reliability in PCB manufacturing and can meet the needs of different fields.