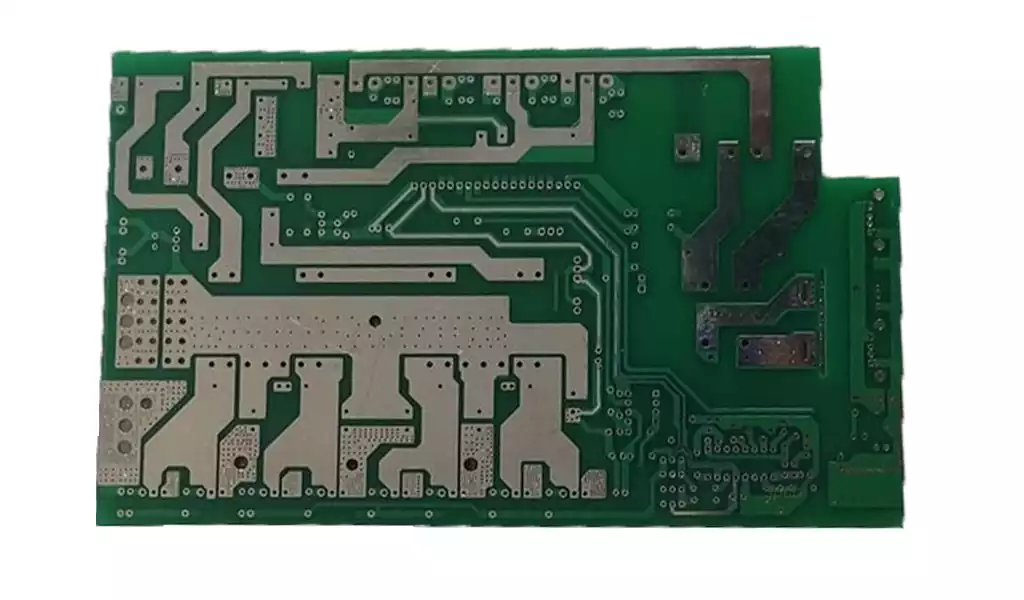

A test point pcb is a substrate on the circuit board of an electronic product that is specially designed for testing purposes. It usually contains one or more sets of Test Points, which are connection points between components on the circuit board for electrical performance testing and diagnostics during manufacturing, repair, or research and development.

Test point pcb is usually clearly labeled and laid out so that testers can quickly and accurately locate the required test points. At the same time, the material and process of the test point substrate also need to comply with the relevant standards and requirements to ensure that it has good conductivity, stability and durability.

Test point pcb plays an important role in the manufacturing, research and development, maintenance and quality control of electronic products, and are a key link in ensuring stable performance and reliability of electronic products.

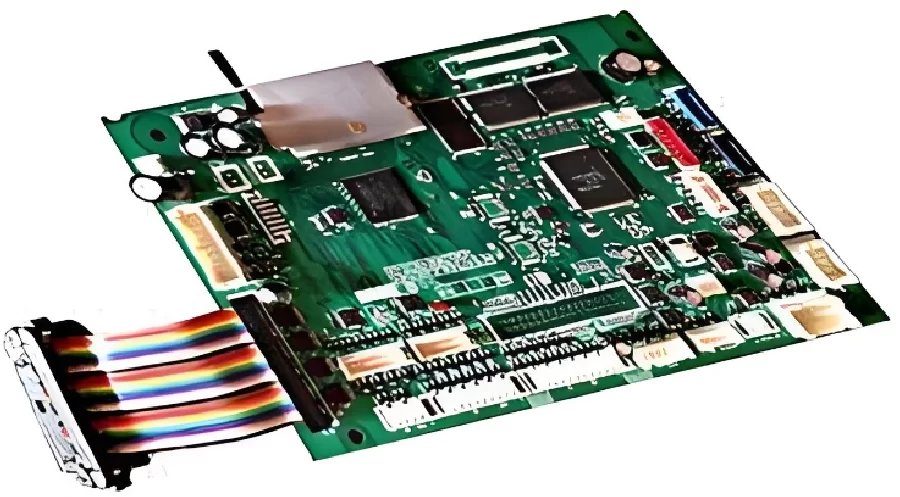

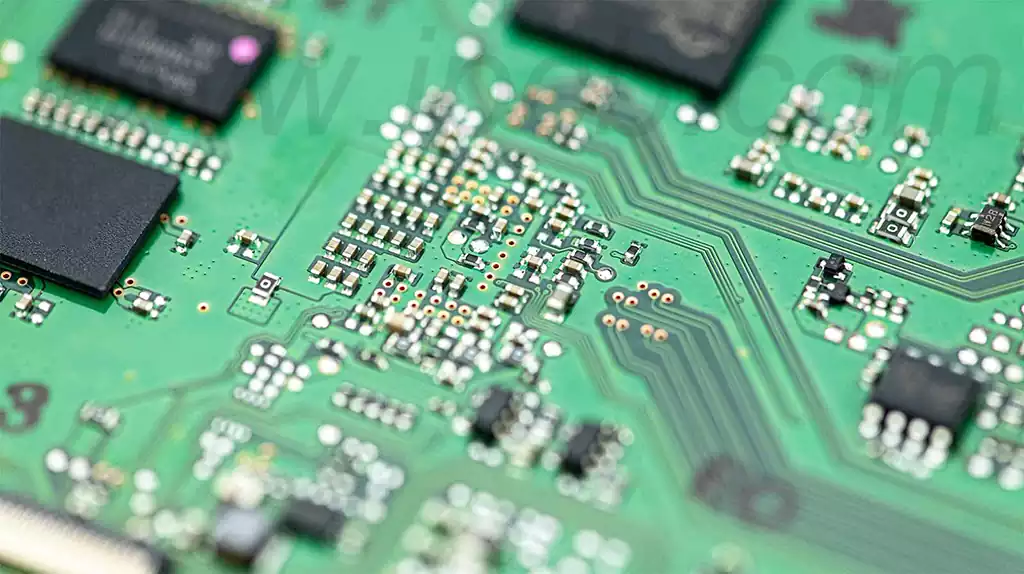

Provide test access points: There are specialized test points designed on the printed circuit board, which are key nodes in the circuit and provide a convenient access point for testers. Testers can use test instruments and tools through these test points to perform various tests on the circuit, such as voltage measurement, current measurement, signal tracing, etc.

Auxiliary troubleshooting: When an electronic product fails, it can help testers quickly locate the problem. By measuring the electrical parameters between different test points, it is possible to determine in which part of the fault occurs, so as to carry out targeted repair and debugging.

Verify circuit function: In the product development and production stage, test point substrates are used to verify the function and performance of the circuit board. By measuring electrical parameters at different test points, it is possible to ensure that the circuits work properly according to the design requirements and meet the performance specifications.

Supporting production testing: In the production line, it is an important part of the automated test system. By connecting test instruments and automated test equipment, the boards can be tested in batches, improving production efficiency and ensuring that each product meets quality standards.

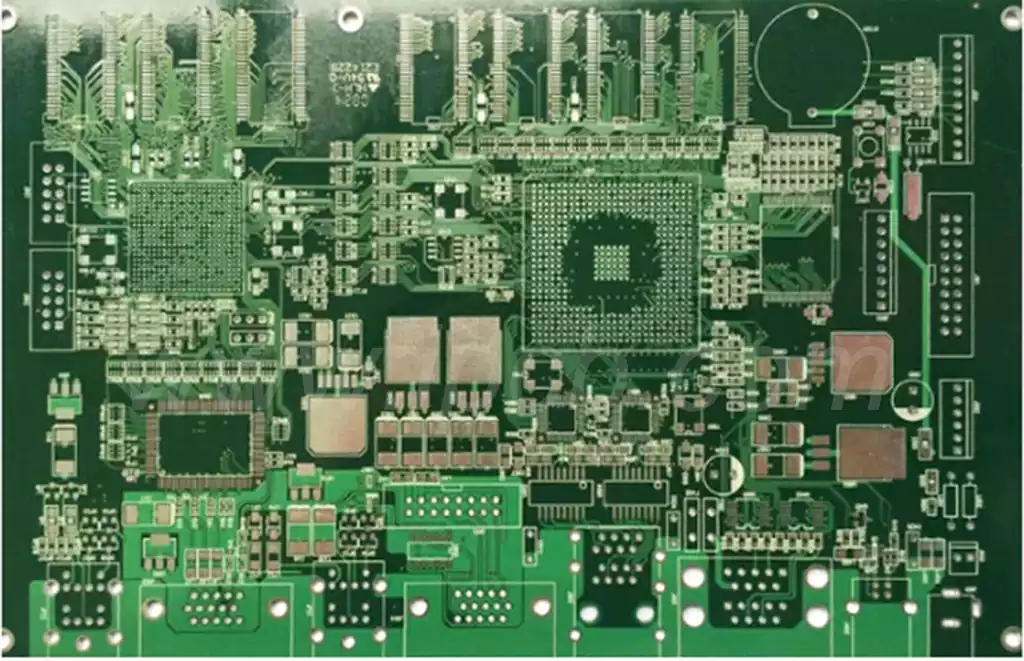

Provide R&D support: It provides a convenient platform for engineers to test and optimize circuit designs during the product development process. Engineers can obtain detailed circuit data, analyze circuit performance, and make improvements and optimizations through test point substrates.

Ensure product quality: The use of test point substrates helps to ensure product quality. Through rigorous testing and verification, potential design flaws and manufacturing problems can be found and fixed in time, thus avoiding product failures in actual use.

In the manufacturing process of electronic products, test point pcb is an important part of quality control and test verification. Through its use, potential problems on the board can be discovered and fixed in time to ensure that the performance and quality of the product meets the design requirements.