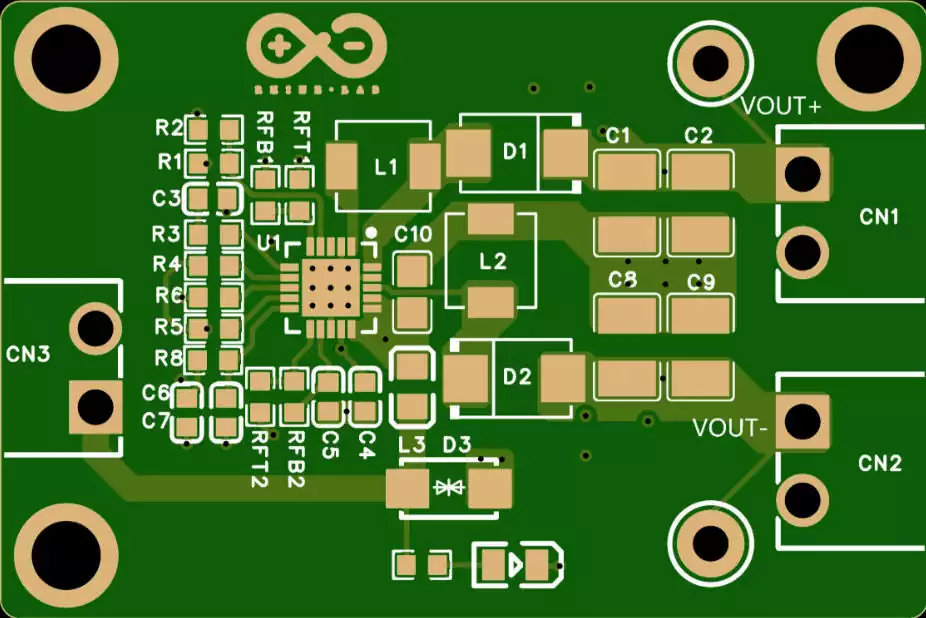

PCB screen printing is a process that transfers special inks onto the substrate surface through a screen stencil to form characters, solder mask patterns, or conductive circuits. Its core difference lies in the need to meet the stringent requirements of the electronics industry for precision, temperature resistance, and adhesion. It supports PCB reliability throughout the entire lifecycle of design, production, assembly, and operation and maintenance, far exceeding its function as a surface identifier.

Standardized screen printing can reduce the SMT placement error rate by over 80%. Clear component designations and package outlines enable precise positioning by automated equipment and manual operations, avoiding circuit faults caused by reversed or misaligned components. During the operation and maintenance phase, the version numbers and batch codes on the screen prints are crucial for troubleshooting and quality traceability, significantly reducing maintenance costs and downtime losses. In terms of safety compliance, screen-printed content such as high-voltage warning signs and certification symbols are necessary for products to meet UL and CE standards, directly avoiding usage risks.

Impact of Screen Printing on PCB Reliability

1.Impact on Electrical Reliability

Electrical reliability is a core indicator of PCBs, relating to the stability and accuracy of signal transmission. Deviations in screen printing precision and ink quality can directly trigger electrical faults. When printing conductive circuits, insufficient screen mesh count or uneven squeegee pressure can result in rough circuit edges and excessive width deviations, which may increase signal transmission losses at best and cause circuit short circuits or open circuits at worst. If pinholes or bubbles appear in the solder mask layer during printing, it can lead to creepage in high-voltage environments, damaging insulation performance. If the solder pad area is covered by solder mask ink (commonly known as “pad blocking”), it can result in poor soldering of components, affecting electrical connection stability.

A automotive electronics company once experienced batch PCB signal interruptions during road tests. Upon inspection, it was found that the conductive ink did not cure sufficiently after printing, causing abnormal fluctuations in circuit resistance values and further degradation of conductivity at high temperatures. In contrast, standardized screen printing processes can improve circuit precision by using 350-450 mesh high-mesh-count screens and ensure sufficient ink sintering by controlling curing temperatures and times, keeping circuit resistance values within the design range and ensuring long-term electrical reliability.

2.Impact on Mechanical Reliability

PCB mechanical reliability is reflected in aspects such as bending resistance, impact resistance, and interlayer adhesion, with the bonding strength between the functional layers formed by screen printing and the substrate being a core influencing factor. For flexible PCBs, if low-quality silver paste is used for printing conductive circuits or the curing temperature is inappropriate, it can result in insufficient adhesion between the circuits and the PI substrate, leading to circuit detachment or breakage after repeated bending. If the solder mask layer is printed too thickly or cured unevenly, it can reduce the surface flatness of the PCB, generating mechanical stress during assembly and making the solder mask layer prone to cracking and detachment during long-term use, exposing the circuits and causing faults.

In addition, the adhesion of the character layer printing also indirectly affects mechanical reliability. If the character ink peels off, it can lead to optical positioning deviations during subsequent maintenance and rework, and forced removal of components may damage the PCB substrate and circuits. By selecting dedicated inks suitable for the substrate and optimizing squeegee pressure and curing parameters, the adhesion of the functional layers can reach industry standards (peel strength ≥ 1.5 N/mm), enhancing the mechanical stability of the PCB.

3.Impact on Environmental Tolerance Reliability

PCBs need to withstand environmental challenges in different scenarios such as consumer electronics, automotive electronics, and industrial control, including high temperatures, high humidity, salt spray, and dust. These complex operating conditions impose stringent requirements on the functional layers formed by screen printing. The solder mask layer, acting as the “protective armor” of the PCB, has its printing quality directly determining environmental tolerance. If the solder mask ink does not cure sufficiently, residual solvents will volatilize in high-temperature and high-humidity environments, causing the solder mask layer to blister and crack, making the circuits vulnerable to water vapor erosion and oxidation. If the substrate surface is not thoroughly cleaned before printing, dust and oil stains can reduce the bonding strength between the solder mask layer and the substrate, making it prone to interlayer delamination in salt spray environments and causing corrosion faults.

Main Risk Points and Avoidance Strategies

1.Poor Quality of Screen Stencils

The stencil is the core of precision control. Deviations in stencil openings or peeling of the photosensitive adhesive can result in shifted printing patterns and rough circuits, causing short circuits, poor soldering, and other issues. A PCB factory once used low-precision stencils, resulting in batch pad blocking during solder mask layer printing, with a component soldering yield of less than 80% and significantly increased rework costs.

Avoidance Strategy: Select stencil materials according types. Rigid PCBs use polyester screens, while flexible and HDI boards use stainless steel screens. For high-precision scenarios, use laser-cut stencils with opening precision controlled within ±5 μm. Before use, check the photosensitive adhesive layer of the stencil to ensure no peeling or burrs, and regularly clean the stencil to avoid residual ink blocking the mesh openings.

2.Improper Ink Selection and Preparation

Ink quality directly determines the performance of functional layers. Using inks that do not match the substrate or losing control of viscosity during preparation can result in insufficient adhesion and abnormal curing. For example, using rigid PCB-specific solder mask inks for flexible PCBs can cause cracking after bending due to insufficient flexibility. If the viscosity of the conductive ink is too low, it can cause circuit spreading and affect electrical performance.

Avoidance Strategy: Select inks according to PCB types and scenarios. Flexible PCBs use highly flexible inks, and high-temperature scenarios use high-temperature-resistant inks. During preparation, control the viscosity, keeping conductive ink viscosity between 8,000-15,000 cP and solder mask ink viscosity between 5,000-8,000 cP, and stir evenly to avoid pigment sedimentation. Use within 48 hours after opening to avoid moisture absorption and deterioration.

3.Imbalanced Printing Parameter Control

Imbalances in parameters such as squeegee pressure, speed, and printing gap can result in uneven printing layer thickness, rough edges, and shifted patterns. Excessive squeegee pressure can damage the substrate and stencil, while insufficient pressure can result in insufficient ink filling. An excessively large printing gap can cause pattern deformation, while an excessively small gap can cause the stencil and substrate to adhere, leading to ink residue.

Avoidance Strategy: Set parameters differentially. For rigid PCBs, use a squeegee pressure of 0.2-0.6 MPa, a speed of 50-100 mm/s, and a gap of 1-3 mm. For flexible PCBs, reduce the pressure to 0.1-0.3 MPa and the gap to 0.5-1 mm, and use a vacuum adsorption platform to fix the substrate. Use a CCD vision alignment system to ensure stencil-substrate alignment deviations ≤ ±10 μm.

4.Non-standardized Curing Processes

Curing is key to the formation of functional layers. Loss of control over temperature and time can result in insufficient ink curing, with residual solvents affecting adhesion and environmental tolerance. A consumer electronics PCB had a 15% blistering rate in the solder mask layer during high-temperature and high-humidity testing due to insufficient pre-baking time of the solder mask layer, seriously affecting product reliability.

Avoidance Strategy: Set curing parameters according to ink types. Conductive inks are cured at 120-150°C for 30-60 minutes, and solder mask inks use a “80°C pre-baking for 30 minutes + 150°C final baking for 60 minutes” stepped process. In UV curing scenarios, control the irradiation time at 30-60 seconds to ensure uniform curing. After curing, conduct sampling inspections and verify adhesion through peel strength tests to avoid insufficient curing.

Screen printing, as the “invisible cornerstone” in PCB manufacturing, has its process precision directly determining product reliability and market competitiveness. From precise matching of material selection to millimeter-level control of parameter adjustment, from strict implementation of curing processes to comprehensive coverage of defect detection, meticulous control in every link is a solemn commitment to PCB reliability.