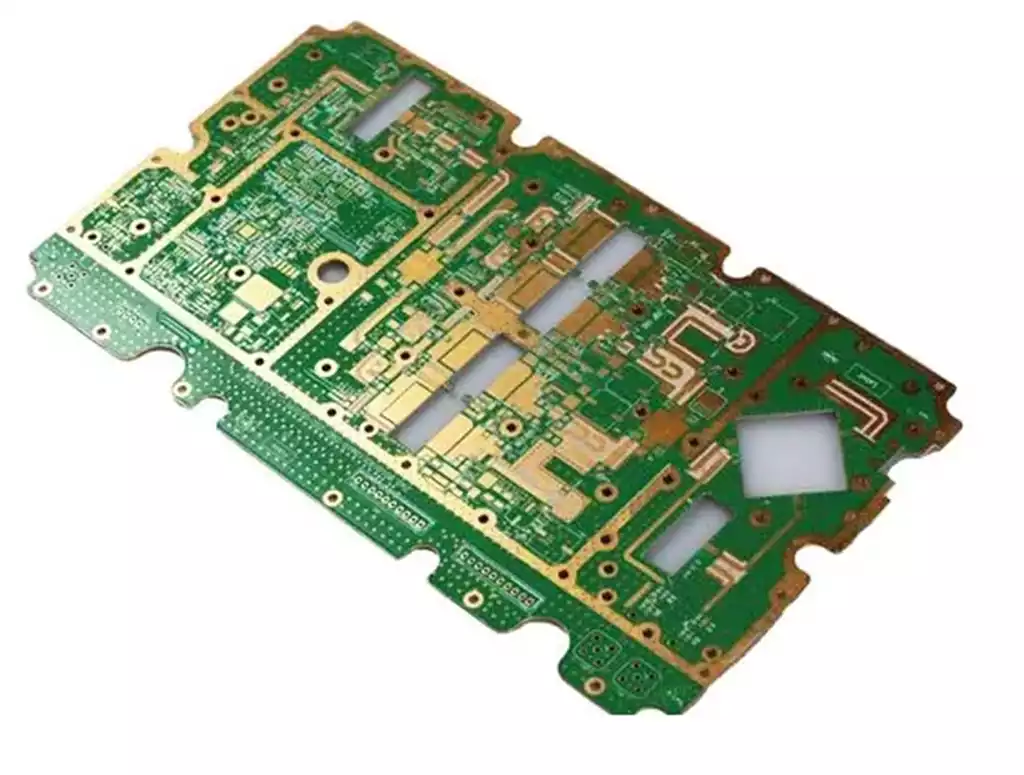

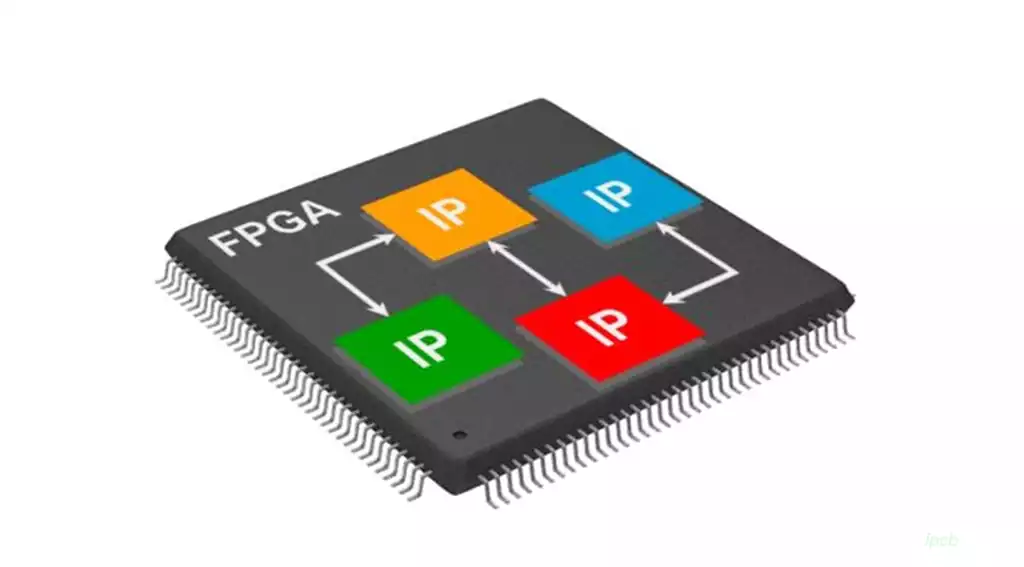

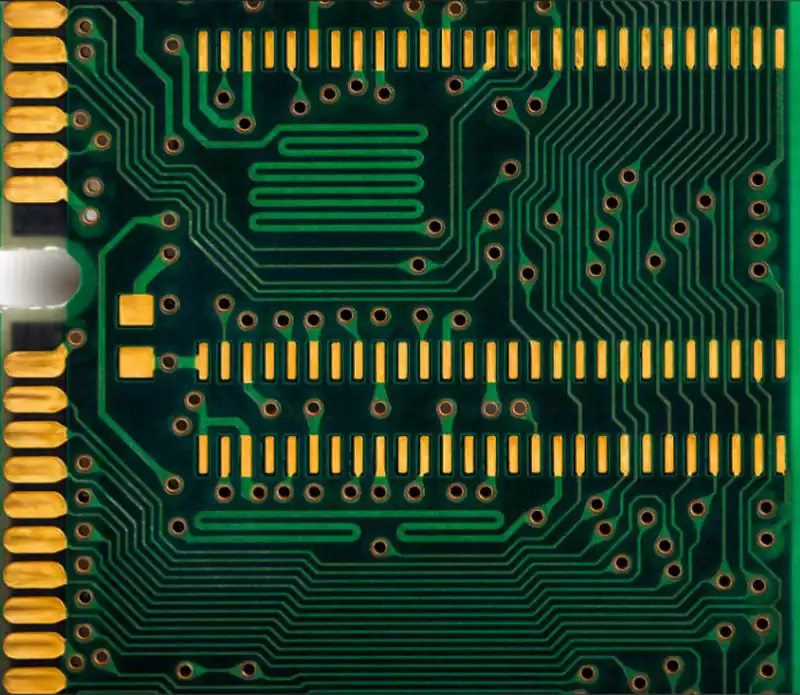

Printed circuit boards, serving as the carrier platform for electronic components and also known as PCBs, are extensively utilised in various electronic devices. Conductive pathways and electronic components are arranged upon the board substrate to facilitate interconnection and control functions between circuits. Integrated circuit chips, as the core components of modern electronic technology, integrate circuit modules, sensing units, signal amplifiers, and converters onto a single carrier. This integration forms the fundamental basis driving the intelligent and miniaturised development of electronic equipment.

Structurally, printed circuit boards typically comprise a substrate material, conductive copper layers, and protective film layers. Substrates may be selected from materials such as glass fibre reinforced boards, resin composite boards, or ceramic substrates. The conductive copper layers form the circuit traces, while the protective film layers cover the circuit surface to prevent component oxidation and trace corrosion. Integrated circuit chips, manufactured using photolithography, represent highly integrated miniature circuit carriers. Their core structure comprises a silicon substrate, metal interconnect layers, and functional components.

Differences between circuit boards and chips:

- Structural Variations

Circuit boards, particularly printed circuit boards (PCBs), are primarily composed of non-conductive materials such as fibreglass or resin, with a conductive copper layer applied to their surface. It connects various electronic components via copper traces, providing physical support and electrical interconnections for the entire circuit. In contrast, a chip is a miniaturised electronic component, typically fabricated from semiconductor materials like silicon, integrating millions of transistors, resistors, capacitors, and other elements internally. - Function and Application

The function of a circuit board is to provide a foundational platform, ensuring efficient transmission of electrical power and signals between electronic components. The chip, however, handles specific signal processing, data computation, or control tasks. For instance, microprocessor chips execute instructions, memory chips manage data storage, while signal processing chips handle audio or video signals.

In practical applications, circuit boards are extensively used in all manner of electronic devices, forming the bedrock of modern electronics. Chips, meanwhile, play a central role within various electronic equipment, such as the CPU and GPU in computers, alongside diverse application-specific integrated circuits (ASICs).

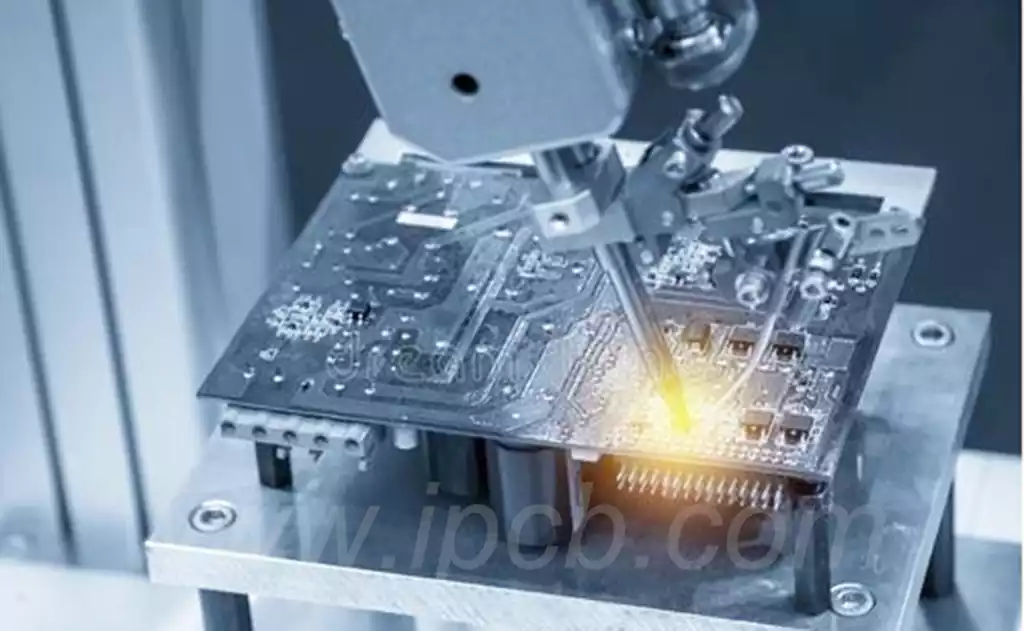

Chip On Board (COB) technology is a method for directly mounting integrated circuit (IC) die onto a circuit board. This technique typically involves bonding the IC die to a substrate composed of materials such as fibreglass epoxy (FR4). Electrical connections between the chip and substrate are achieved through screen-printed conductive paste and wire bonding techniques.

Applications of Printed Circuit Boards (PCBs):

- Communications: PCBs form a critical component of communication devices such as mobile phones, radios, and radar systems. These devices require high-precision PCBs to facilitate signal transmission and processing.

- Computing: Within computer hardware, printed circuit boards play a vital role in connecting various components. From early desktop computers to modern laptops and tablets, high-quality printed circuit boards are indispensable.

- Consumer Electronics: With the accelerating pace of modern life, demands for convenience continue to rise. Various consumer electronics, including smartphones, smartwatches, and in-car navigation systems, rely on printed circuit boards to fulfil their functional requirements.

- Automotive: With advancing intelligent technologies, the automotive industry relies increasingly on printed circuit boards. These boards are integral to vehicle control systems, navigation systems, and diverse sensor applications.

- Aerospace: Given the unique operational environments, electronic equipment in aerospace demands exceptional reliability and stability. Consequently, stringent requirements and standards govern the production and use of printed circuit boards in this sector.

The application of chip-on-board technology offers significant advantages for electronic devices:

- Space Optimisation: By eliminating traditional chip packaging steps, board-level chip technology reduces the overall size of electronic devices, enabling more compact designs.

- Cost Efficiency: Direct chip mounting on the circuit board minimises intermediate processes such as packaging and testing, thereby lowering production costs.

- Performance Enhancement: Reduced connection resistance and inductance between chips and circuit boards improve signal transmission speeds and circuit performance.

Printed circuit boards and chips, as the twin pillars of electronic technology, fulfil dual roles as physical carriers and functional cores. The former provides a stable structural foundation for interconnecting electronic components, while the latter drives intelligent upgrades through highly integrated processing capabilities. The advent of chip-on-board (COB) technology further paves new pathways for miniaturisation and efficiency in electronic devices through spatial optimisation, cost reduction, and performance enhancement. From telecommunications equipment to aerospace, and from consumer electronics to smart vehicles, their synergistic innovation continually reshapes the boundaries of modern technology. Looking ahead, breakthroughs in materials science and manufacturing processes will deepen the integration of printed circuit boards and chips, injecting stronger momentum into the era of universal connectivity.