Rigid PCB, commonly referred to simply as PCBs, are what most people envision when thinking of circuit boards. These boards utilise conductive tracks and other components arranged upon a non-conductive substrate to connect electrical components. In rigid circuit boards, the non-conductive substrate typically incorporates glass cloth, which enhances the board’s strength and imparts rigidity. Rigid circuit boards provide excellent support for components and offer good thermal resistance.

Although flexible PCBs feature conductive traces on non-conductive substrates, this type of circuit board employs flexible base materials such as polyimide (PI). The flexible substrate enables the circuit to withstand vibration, dissipate heat, and fold into various shapes. Owing to these structural advantages, flexible circuits are increasingly favoured for compact devices such as smart wearables, mobile phones, and cameras.

In recent years, the consumer electronics market, spearheaded by mobile devices like smartphones and tablets, has experienced rapid growth. The trend towards smaller, thinner, and lighter devices has become increasingly pronounced. Consequently, traditional rigid PCBs can no longer meet product requirements. Major manufacturers have therefore begun researching novel technologies to replace PCBs. Among these, FPC stands as the most favoured technology and is becoming the primary connectivity component in electronic devices. Furthermore, driven by emerging markets such as 5G and wearable devices, FPC is poised to enter a new phase of growth.

Comparison of Rigid PCB and Flex PCB

Current Carrying Capacity of Wires

Compared to rigid circuit boards, flexible circuit boards exhibit relatively poorer heat dissipation properties. To account for heat dissipation in flexible circuit boards, additional width or spacing must be allocated for the conductors.

Shape

Typically, rectangular shapes optimise substrate utilisation, with sufficient margins near edges. Sharp internal corners may cause panel tearing. Consequently, FPC conductor widths and spacings should be minimised, with transitions rendered as smooth as possible. Acute angles inherently concentrate stress, leading to lead failure.

Structural Materials

FPC: Utilises flexible substrates such as polyester or polyimide film, enabling diverse forms including bending and folding.

Rigid PCB: Employs rigid substrates like FR-4 fibreglass composite, typically forming a rigid structure.

Design Flexibility

FPC: Suited for product designs requiring complex shapes involving bending or folding, such as mobile phones and wearable devices, owing to its flexible nature.

Rigid PCB: Suited for standardised product designs with minimal mechanical performance requirements, such as computer motherboards and power supply boards.

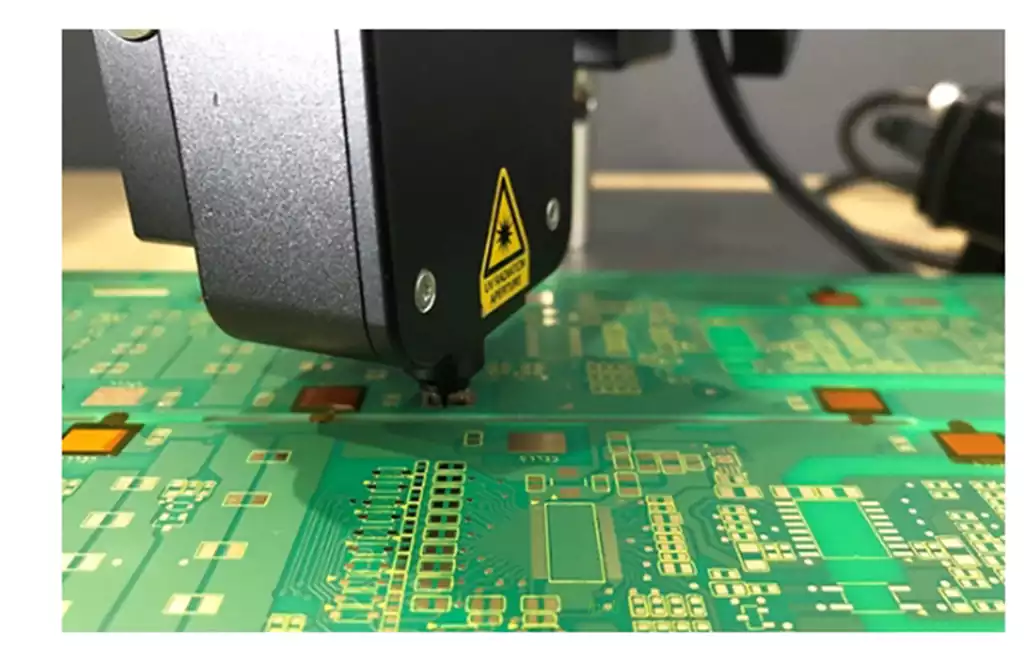

Solder Mask

Rigid PCBs feature a solder mask on both sides. This mask contains gaps exposing SMT pads or PTH holes to permit component assembly. FPCs typically employ a cover coat rather than a solder mask. The cover film is a thin polyimide material that can be drilled or laser-cut to expose component contacts.

Manufacturing Process

Most manufacturing steps for FPC and rigid PCBs are similar. However, FPC requires specialised tools to secure it in position due to its flexibility. Flexible FPC does not utilise solder mask; instead, a process called cover film or cover layer is employed to protect the exposed circuit patterns on the flexible PCB.

Cost

Purely in terms of price, FPCs are more expensive than rigid PCBs. However, FPCs offer numerous benefits in enhancing cost-effectiveness, such as space savings, weight reduction, and high reliability.

Application Areas for FPC and Rigid PCB

FPC Applications

Mobile Phones: Emphasising the lightweight and thin profile of flexible circuit boards. Effectively reduces product volume and facilitates seamless integration with batteries, microphones, and keypads.

Computers and LCD screens: Utilising the integrated circuit layout and slim profile of flexible circuits, digital signals are converted into visual displays presented via LCD screens.

CD Walkmans: Emphasising the three-dimensional assembly capability and thin profile of flexible circuits, transforming bulky CD players into portable companions.

Disk drives: Both hard and floppy disk drives rely heavily on FPC’s high flexibility and ultra-thin 0.1mm thickness to achieve rapid data access, whether in PCs or notebooks;

Hard disk drives: Constituent elements including suspended circuits and encapsulation boards.

Latest applications: Bluetooth headsets, VR headsets, smartwatches, drones, and other compact devices.

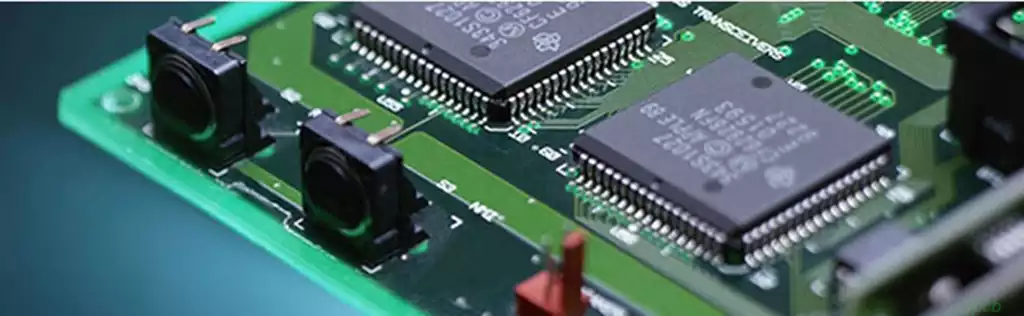

Rigid PCB Application Domains

Communication Equipment: Routers, switches, and other network devices frequently employ PCBs as primary circuit board types.

Consumer Electronics: PCBs see widespread application in household appliances and digital products, such as televisions and audio equipment.

Industrial Control: Industrial machinery and automated control systems require stable, reliable circuit boards, often utilising PCBs.

Aerospace: The aerospace sector demands lightweight and highly reliable electronics, with PCB circuit designs selected for specific applications.

Whether traditional rigid PCB or innovative flexible PCB, both are indispensable components in modern electronics. Each leverages its unique structural materials and design flexibility to play a critical role in specific application domains. As consumer electronics trend towards miniaturisation and slim profiles, coupled with the emergence of new markets like 5G and wearable devices, flexible FPCs demonstrate significant potential in compact devices such as smartphones and VR headsets due to their bendable and foldable properties. Meanwhile, rigid PCBs remain the preferred choice for stability and reliability in sectors like communications equipment and industrial control systems.