PCB board clamp usually refers to fixtures used to hold PCBs (printed circuit boards) in place. In the production of electronic equipment, PCB board clamps are used to ensure that circuit boards remain stable during assembly and soldering processes, preventing them from moving or being damaged. Such clamps can be simple plastic or metal structures designed to snap onto the PCB board and securely fasten it to the workbench by means of screws or other fixing mechanisms. This ensures precise positioning and stability during the production process, thereby improving product quality and productivity.

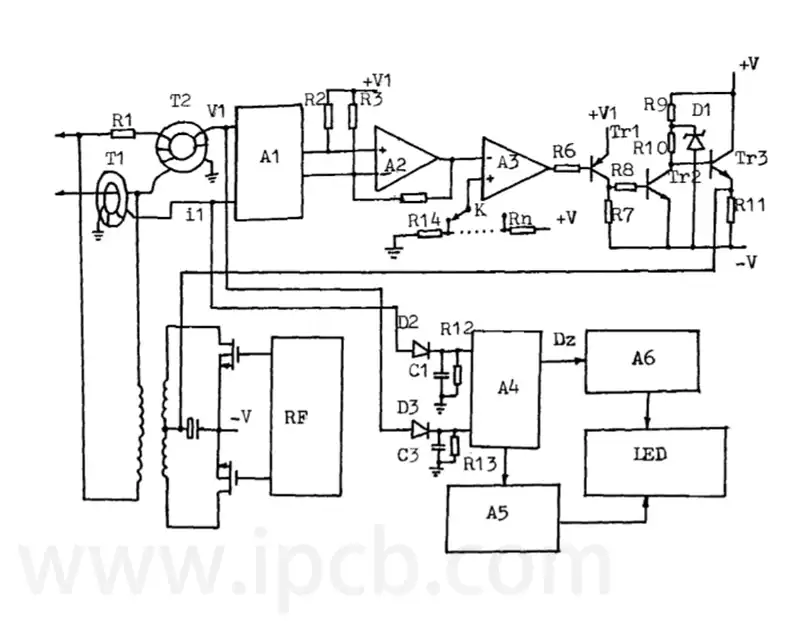

PCB board clamp plays a key role in the circuit board production process. As the core part of an electronic product, the quality and performance of the circuit board is directly related to the stability and reliability of the entire machine. As a tool for fixing circuit boards, board clamps can ensure that circuit boards remain in a stable position during the manufacturing process, avoiding movement and deformation. Reasonable use of the board clamps, help to improve the processing accuracy and overall quality of the circuit board, to reduce the waste and errors in manufacturing.

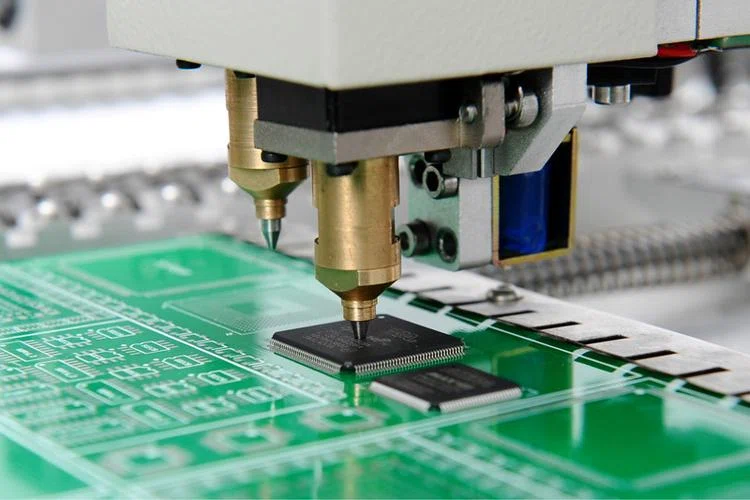

PCB board clamp also plays an important role in the welding and connection of electronic components. Electronic components need to be precisely connected to ensure the normal operation of the equipment, the board is responsible for stabilising the position of the components, so that it does not shift or move when welding, thus ensuring the accuracy and stability of the welding to prevent product failures due to poor welding quality or positional dislocation.

In the assembly of electronic products, PCB board clamp is also indispensable tool. The assembly process is complex and requires precision, each part must be accurately coordinated. The pcb board clamp ensures that the parts are in the correct position by clamping them, assisting in the realisation of high-precision assembly and improving the quality of product assembly.

PCB board clamp also plays an important role in the testing and debugging stages of electronic products. Finished electronic equipment undergoes a number of tests and debugging to ensure that performance is up to standard before it is released to the market. Board clamps can firmly fix the equipment, maintain a stable state, reduce the interference and errors generated during the test process, improve the accuracy and reliability of the test data to ensure product quality in line with standards.

How to choose the right PCB board clamp for your production line?

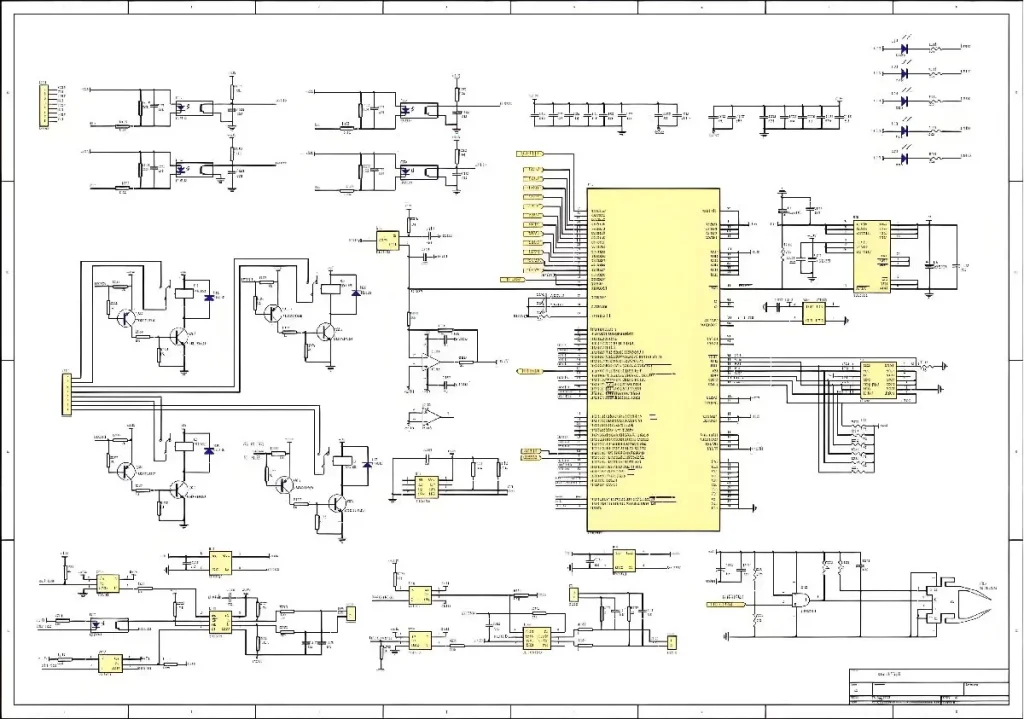

- According to the size and shape of the PCB board to choose the right pcb board clamp specifications

Size matching: the pcb board clamp must meet the PCB size range used in the production line to avoid clamping in place or waste of space. For example, some production lines have strict restrictions on the width of the board, such as board width ≤ 260mm or ≤ 300mm requirements, should choose the appropriate specifications of the fixture.

Shape fit: the board fixture design should try to fit the PCB board shape, support square, rectangular and other forms of board splicing, and support the closed-loop design of the board splicing, to ensure the stability of the clamping process and not deformed.

Multi-track support: support for multiple loading tracks and independent belt drive, to facilitate the flexible clamping and automated feeding of single boards or patchwork boards.

- Select the fixture type according to the degree of automation and process requirements of the production process.

Automation compatibility: If the production line requires automatic board feeding and receiving, choose fixtures with automatic clamping and releasing mechanisms, such as pneumatically driven clamping frames, to ensure fast and efficient loading and unloading and board clamping processes.

Flexible clamping design: Adopting adjustable clamping force clamping structure to avoid excessive pressure on PCB, especially suitable for flexible PCB or thin circuit board.

Double-sided processing support: support PCB flip clamping, convenient for double-sided assembly and processing, to enhance the flexibility and efficiency of the production line.

- According to the layout of production line equipment and space limitations to choose the appropriate structural design.

Volume and space occupation: When limited by the production line space, choose the fixture with compact size and small footprint to avoid the impact on the factory area and leave more space for other equipment.

Modularity and standardisation: the modular design of the fixture is convenient to interface with existing SMT equipment and easy to maintain and expand.

Convenient installation and maintenance: fixtures should be easy to install, replace and maintain, reduce equipment downtime, improve production continuity

PCB board clamp has an important application value in the electronics industry, it can play a key role in circuit board production, electronic parts welding and connection, electronic product assembly, as well as product testing and debugging.