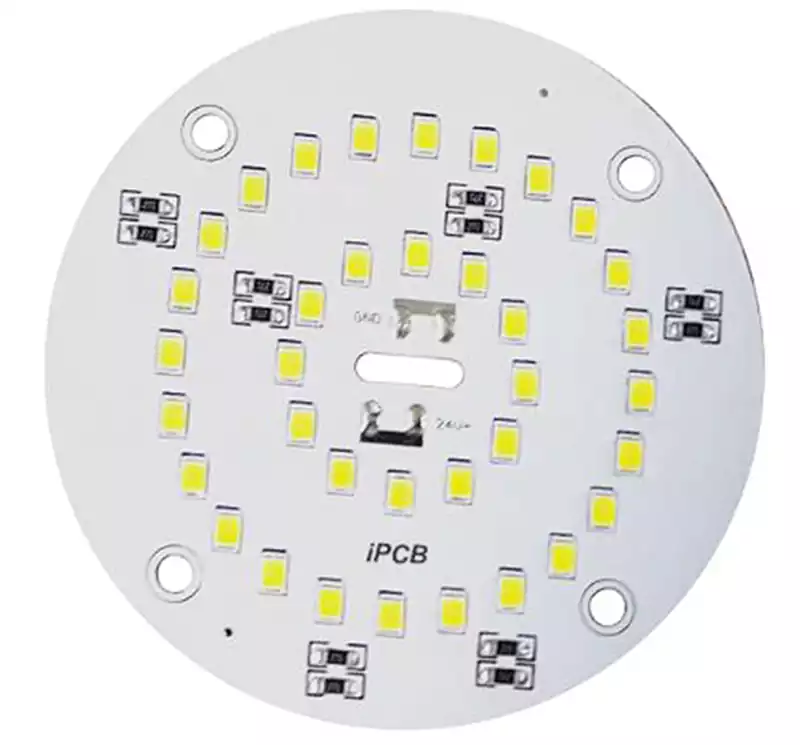

Thermal Clad PCB is an advanced circuit board technology that improves the heat resistance, insulation and mechanical strength of circuit boards by adding a layer of thermal laminate material on top of traditional printed circuit boards. This innovative technology enables thermal laminate printed circuit boards to maintain stable performance in high-temperature environments, providing reliability for a variety of demanding application scenarios.

Thermal laminates offer the following significant advantages over conventional printed circuit boards:

Excellent heat resistance: Thermal cladding materials are able to withstand high temperature environments, effectively preventing deformation and performance degradation of circuit boards at high temperatures and improving the stability and reliability of equipment.

Strong insulation properties: good insulation properties, can effectively reduce electromagnetic interference between circuits, to ensure the normal operation of electronic equipment in the complex electromagnetic environment.

High mechanical strength: high mechanical strength, able to withstand a variety of external shock and vibration, improving the durability and reliability of the equipment.

Good processing performance: the thermal cladding material has good processing performance, which is convenient for cutting, drilling, bending and other processing operations, and improves production efficiency and product quality.

Manufacturing Process:

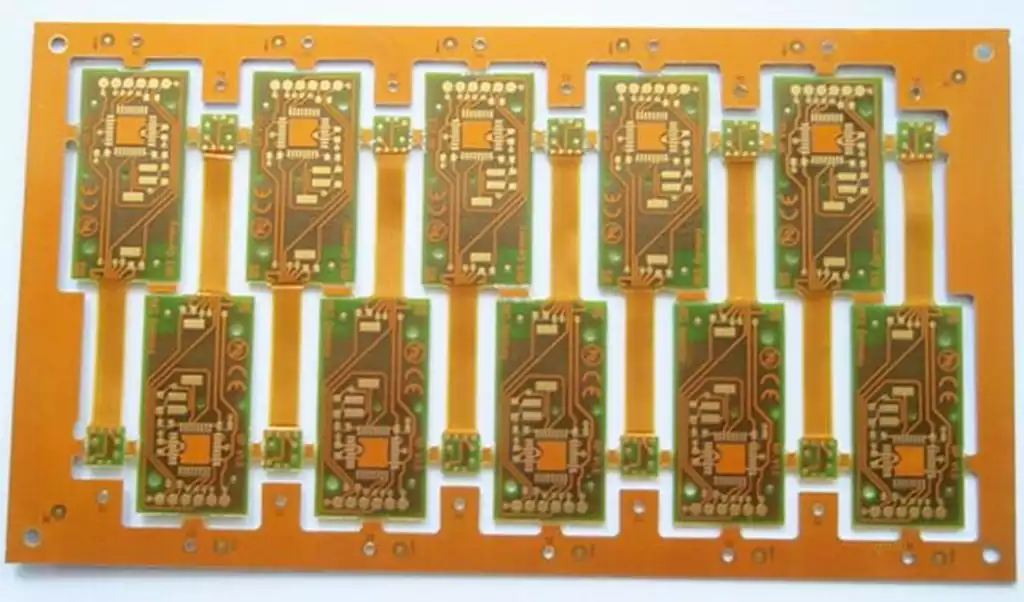

Design: Design the circuit board according to the requirements, including determining the size, layout and wiring of the board.

Pre-treatment: Pre-treat the substrate by cleaning, drying, etc. to ensure that the substrate surface is clean and free of impurities.

Coating: Coating the substrate with a layer of thermally coated material, which provides good insulation and heat resistance.

Circuit production: On the substrate coated with the thermal coating material, the circuit lines are produced by printing, photolithography and other techniques.

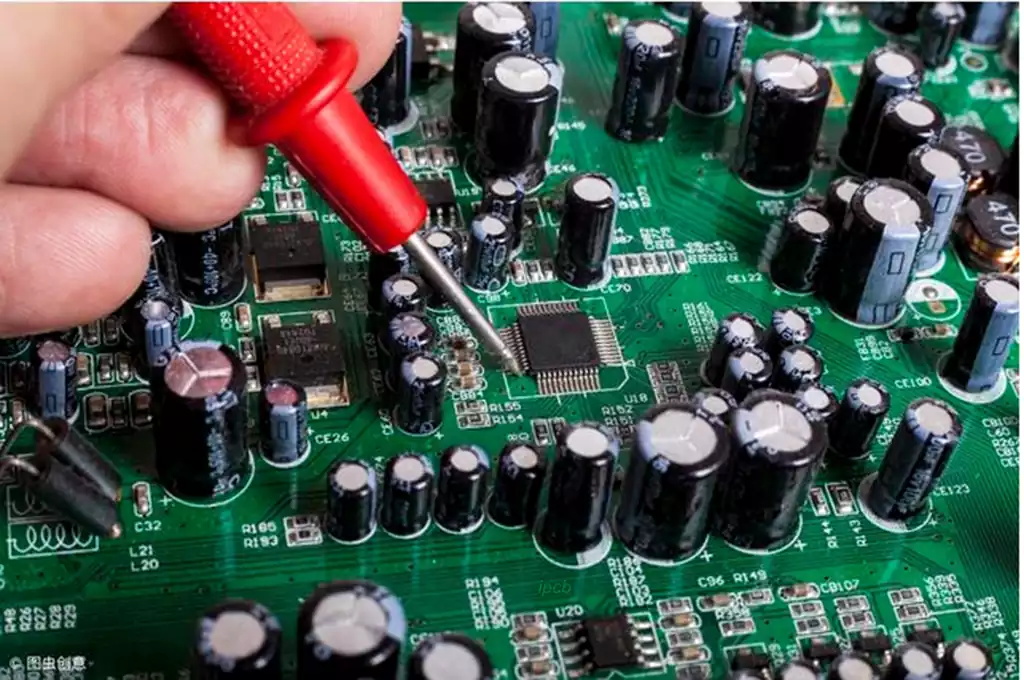

Component Mounting: Mounting electronic components onto circuit boards.

Soldering: Connecting components to conductive paths on circuit boards through soldering.

Inspection and Repair: Inspection of circuit boards, repair or rework of unqualified circuit boards.

Assembly and Integration: Multiple boards are assembled and integrated as required to form a complete thermal clad pcb.

Test and Verification: Test and verify the completed thermal cladding printed circuit boards to ensure that their performance meets the requirements.

Packaging and Transportation: The qualified boards are properly packaged and labeled to ensure that they are not damaged during transportation and storage.

Thermal Clad PCB has a wide range of applications in many fields, including the following:

Automotive electronics: With the improvement of automotive electronics, the PCB board is widely used in automobiles, such as engine control, brake system control, suspension system control, and so on.

Industrial control: In the field of industrial control, it is used in various control systems, such as robot control, automation equipment control, etc.

Medical Equipment: Medical equipment requires high reliability and stability. Thermal laminated printed circuit boards are widely used in medical equipment, such as monitors, electrocardiographs, respiratory machines, etc., due to their excellent performance.

Aerospace: In the aerospace field, due to the high-reliability requirements of the equipment, it is used in the electronic systems of various airplanes and spacecraft.

Communication Equipment: In the field of communication, it is used in various communication equipments such as base stations, switches and routers.

Consumer Electronics: In the field of consumer electronics, it is widely used in a variety of electronic products, such as smart phones, tablet PCs, TVs, and so on.

As an innovative technology and solution, thermal clad pcb provides higher performance, greater stability and reliability for modern electronic products.