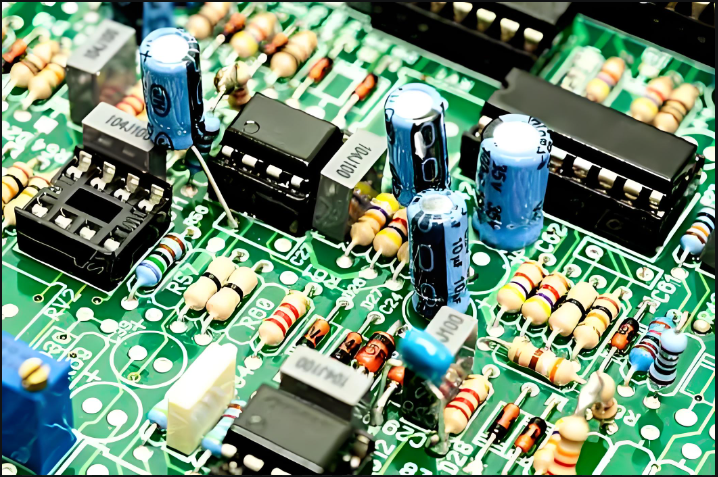

In the realm of electronics and PCB (Printed Circuit Board) design, accurately identifying components is crucial for successful assembly and repair. A circuit board component identifier plays a vital role in this process, enabling designers, engineers, and technicians to manage and understand the components on a board efficiently. This article delves into the importance of circuit board component identifiers, how they function, and their impact on PCB design and manufacturing.

What is a Circuit Board Component Identifier?

A circuit board component identifier is a unique label or code assigned to each component on a PCB. This identifier serves as a reference to the specific part and its location on the board. It aids in various stages of the PCB lifecycle, including design, assembly, testing, and repair. By providing a standardized way to reference components, identifiers facilitate communication among engineers, streamline the assembly process, and ensure consistency across different stages of the project.

Importance of Component Identifiers

The significance of a circuit board component identifier cannot be overstated. These identifiers are crucial for several reasons:

- Ease of Identification: Component identifiers make it easier to locate and identify parts on a PCB. This is particularly important during assembly and troubleshooting, where knowing the exact position and type of each component can save time and reduce errors.

- Standardization: Identifiers provide a standardized method for referencing components, ensuring that everyone involved in the project uses the same terminology. This reduces the risk of confusion and miscommunication, especially in complex projects with multiple team members.

- Documentation: Accurate component identifiers are essential for creating comprehensive documentation. This includes schematics, assembly instructions, and maintenance manuals. Proper documentation helps in understanding the circuit design and aids in future repairs or modifications.

- Inventory Management: For manufacturers and repair facilities, having clear component identifiers simplifies inventory management. It allows for easy tracking of parts, reduces the likelihood of errors in part ordering, and helps in maintaining an organized inventory system.

How Circuit Board Component Identifiers Work

Component identifiers are typically assigned based on a standardized system. The most common practice is to use a combination of letters and numbers to create a unique code for each part. This code often includes information about the type of component, its value, and its location on the board.

Common Systems for Component Identification

- Alphanumeric Codes: Many PCBs use alphanumeric codes to identify components. For example, resistors might be labeled as R1, R2, etc., while capacitors could be labeled as C1, C2, and so on. This system helps in quickly distinguishing between different types of components and their respective positions.

- Reference Designators: Reference designators are another common method for identifying components. These are standardized codes assigned according to the component type, such as R for resistors, C for capacitors, and U for integrated circuits. Each component gets a unique number within its category, making it easy to locate and reference.

- Location Codes: Some PCB designs use location codes to indicate where a component is situated on the board. These codes may correspond to specific areas or sections of the PCB, helping in quick identification during assembly or repair.

Implementing Component Identifiers in PCB Design

Incorporating circuit board component identifiers into PCB design involves several key steps:

- Design Phase: During the design phase, engineers assign identifiers to each component based on the design requirements. This involves creating a schematic diagram where each component is labeled with its identifier. The design software used for PCB layout often includes tools to automatically generate and assign these identifiers.

- Assembly Phase: In the assembly phase, the PCB is populated with components according to the identifiers. This process is often automated using pick-and-place machines that place components on the board based on the identifiers provided in the design files.

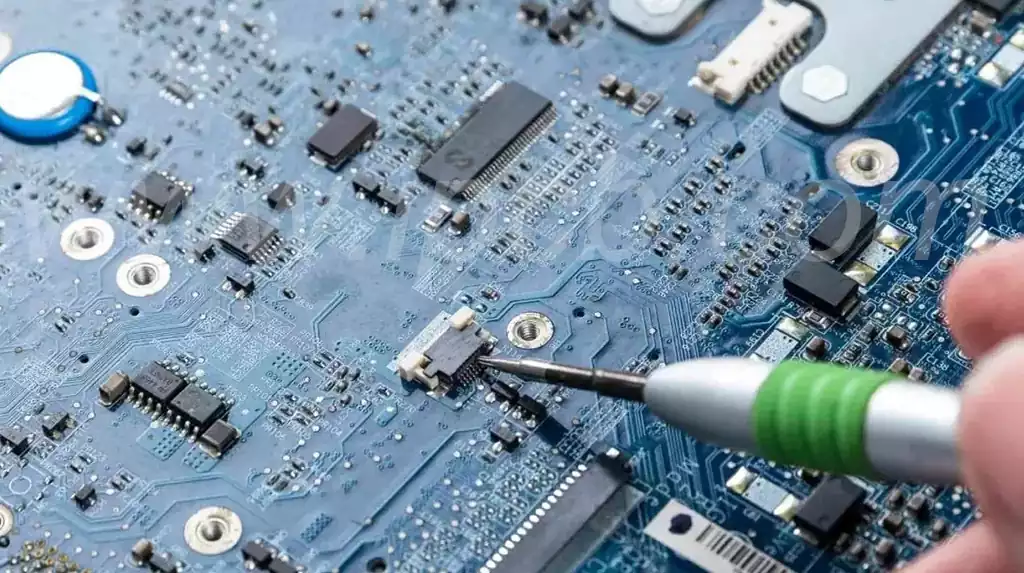

- Testing and Validation: After assembly, testing and validation ensure that all components are correctly placed and functioning. The circuit board component identifiers help technicians verify that the correct parts are in the right locations, facilitating efficient testing and troubleshooting.

- Repair and Maintenance: For repairs and maintenance, having clear component identifiers is essential. Technicians use these identifiers to quickly locate and replace faulty components. Accurate identifiers ensure that the correct parts are used and help in maintaining the board’s overall functionality.

Impact of Component Identifiers on PCB Manufacturing

The use of circuit board component identifiers has a significant impact on PCB manufacturing:

- Efficiency: Identifiers streamline the manufacturing process by providing a clear reference for each component. This efficiency is crucial in high-volume production, where time and accuracy are critical.

- Quality Control: With accurate component identifiers, quality control processes can be more effective. Inspectors and testers can quickly verify that the correct components are used and are in the right positions, reducing the likelihood of defects.

- Cost Management: Effective use of component identifiers can help manage costs by reducing errors and rework. Accurate identification minimizes the risk of using incorrect parts, which can lead to costly repairs or replacements.

- Collaboration: Component identifiers facilitate collaboration among different teams involved in PCB design and manufacturing. Clear and standardized references help in ensuring that all team members are on the same page, reducing the risk of miscommunication and errors.

Challenges and Considerations

While circuit board component identifiers offer numerous benefits, there are also challenges to consider:

- Complexity: For highly complex PCBs with numerous components, managing and assigning identifiers can be challenging. Ensuring that each component has a unique and easily understandable identifier requires careful planning and organization.

- Updating Identifiers: During design changes or revisions, updating component identifiers can be time-consuming. It is essential to keep all documentation and design files synchronized with the latest identifiers to avoid confusion.

- Compatibility: Ensuring that the identifier system used is compatible with various design and manufacturing tools is crucial. Different tools and software may have different requirements for how identifiers are formatted and used.

Future Trends in Component Identification

As technology evolves, new trends are shaping the way component identifiers are used:

- Automated Systems: Advances in automation are making it easier to assign and manage component identifiers. Automated systems can quickly generate and apply identifiers, improving efficiency and reducing the risk of human error.

- Smart Labels: The use of smart labels and RFID technology is becoming more prevalent. These technologies allow for more advanced tracking and identification of components, providing real-time data on their status and location.

- Integration with Design Software: Enhanced integration between component identifiers and design software is streamlining the design and manufacturing process. This integration allows for better management of identifiers and improved accuracy in the production process.

Conclusion

A circuit board component identifier is a fundamental aspect of PCB design and manufacturing. By providing a clear and standardized way to reference components, identifiers play a crucial role in ensuring efficiency, accuracy, and reliability in the production and maintenance of PCBs. Despite the challenges, the benefits of using component identifiers are substantial, contributing to better organization, quality control, and cost management.

As technology continues to advance, the methods and tools for managing component identifiers will also evolve. Staying informed about these developments can help engineers and manufacturers make the most of these tools, leading to more effective and streamlined PCB design and manufacturing processes.

Understanding and implementing effective circuit board component identifiers is essential for anyone involved in PCB design and production. By recognizing their importance and addressing the challenges, professionals can ensure that their PCB projects are successful and meet the highest standards of quality and performance.