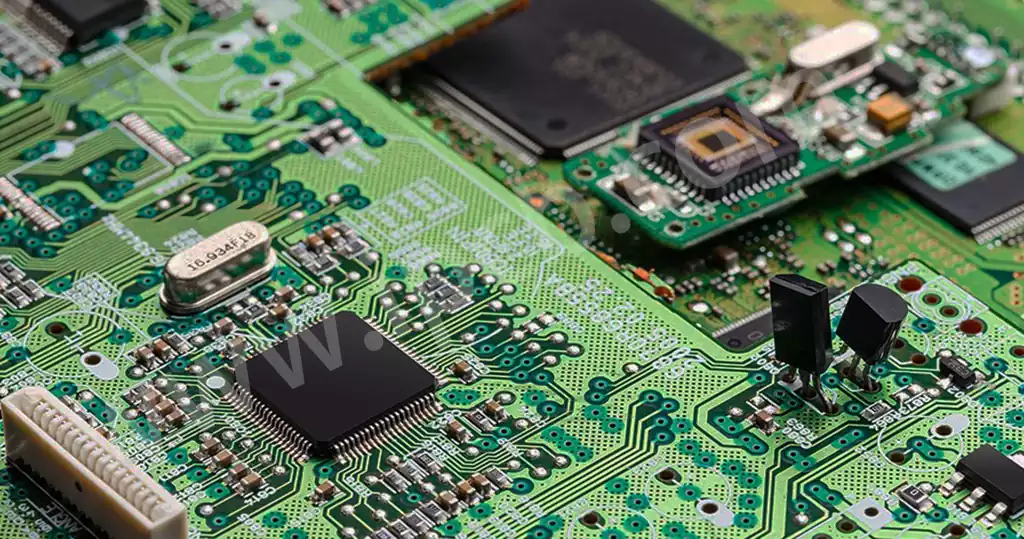

Printed circuit boards are indispensable basic components in modern electronic devices. Its applications are extremely broad, covering a wide range of industries such as industrial, agricultural, aerospace, automotive and medical.

What are printed circuit boards used for?

Industrial Applications

Printed circuit boards play an important role in the industrial sector. Thick copper PCBs are commonly used in industrial machinery to meet high power and high current requirements. Specific applications include motor controllers, industrial load testers, and high-current battery charging equipment that require reliable electrical connections and signal transmission.

Automotive Electronics

In modern automobiles, printed circuit boards are used in a wide range of electronic control systems. These boards can withstand constant vibration and harsh environmental conditions to ensure reliable performance of automotive electronics. In addition, automotive circuit boards are subjected to rigorous testing, such as thermal shock and humidity cycling, to ensure that their performance is not compromised.

Consumer Electronics

Consumer electronics is one of the major markets for PCB manufacturers. From cell phones and tablets to home appliances, every electronic device relies on printed circuit boards for its individual functions. These appliances often contain multiple active and passive components, which the board connects to fulfill complex functions.

Aerospace

The aerospace industry places extreme demands on circuit boards, requiring these components to withstand extreme temperatures and intense turbulence. Aerospace printed circuit boards are not only lightweight and oxidation-resistant, they also undergo rigorous testing procedures to ensure that they work well under harsh conditions.

Medical Devices

As medical technology advances, new medical tools are being developed, most of which rely on printed circuit boards for operation. PCBs in medical equipment need to be designed for high reliability and durability to cope with complex operating environments and high precision requirements.

Military Applications

Military-grade printed circuit boards need to maintain a high level of durability and reliability under extreme conditions. Due to the diversity of military applications, manufacturers need to provide different types of boards with rigorous testing procedures to meet high performance requirements to minimize the risk of failure.

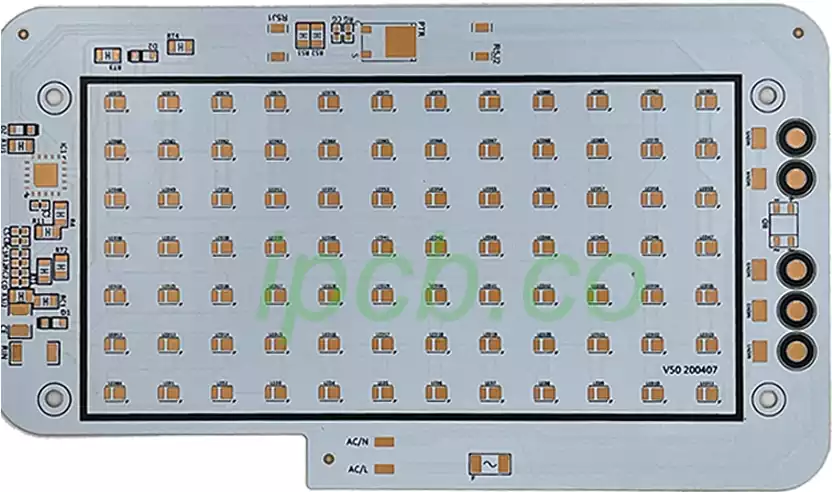

Lighting Industry

In the lighting industry, LED bulbs are gradually replacing traditional incandescent and compact fluorescent lamps, and PCB boards are therefore widely used in the manufacture of LED lamps. Aluminum-based PCBs are favored for their excellent heat dissipation properties, ensuring that LED lamps work efficiently without overheating.

Printed circuit boards are indispensable basic components in modern electronic devices. Its applications are extremely broad, covering a wide range of industries such as industrial, agricultural, aerospace, automotive and medical.

Industrial Applications

Printed circuit boards play an important role in the industrial sector. Thick copper PCBs are commonly used in industrial machinery to meet high power and high current requirements. Specific applications include motor controllers, industrial load testers, and high-current battery charging equipment that require reliable electrical connections and signal transmission.

Automotive Electronics

In modern automobiles, printed circuit boards are used in a wide range of electronic control systems. These boards can withstand constant vibration and harsh environmental conditions to ensure reliable performance of automotive electronics. In addition, automotive circuit boards are subjected to rigorous testing, such as thermal shock and humidity cycling, to ensure that their performance is not compromised.

Consumer Electronics

Consumer electronics is one of the major markets for PCB manufacturers. From cell phones and tablets to home appliances, every electronic device relies on printed circuit boards for its individual functions. These appliances often contain multiple active and passive components, which the board connects to fulfill complex functions.

Aerospace

The aerospace industry places extreme demands on circuit boards, requiring these components to withstand extreme temperatures and intense turbulence. Aerospace printed circuit boards are not only lightweight and oxidation-resistant, they also undergo rigorous testing procedures to ensure that they work well under harsh conditions.

Medical Devices

As medical technology advances, new medical tools are being developed, most of which rely on printed circuit boards for operation. PCBs in medical equipment need to be designed for high reliability and durability to cope with complex operating environments and high precision requirements.

Military Applications

Military-grade printed circuit boards need to maintain a high level of durability and reliability under extreme conditions. Due to the diversity of military applications, manufacturers need to provide different types of boards with rigorous testing procedures to meet high performance requirements to minimize the risk of failure.

Lighting Industry

In the lighting industry, LED bulbs are gradually replacing traditional incandescent and compact fluorescent lamps, and circuit boards are therefore widely used in the manufacture of LED lamps. Aluminum-based PCBs are favored for their excellent heat dissipation properties, ensuring that LED lamps work efficiently without overheating.

As technology continues to evolve, the application of printed circuit boards is facing a number of new trends. These trends are not only driven by market demand, but also closely related to new technological advances.

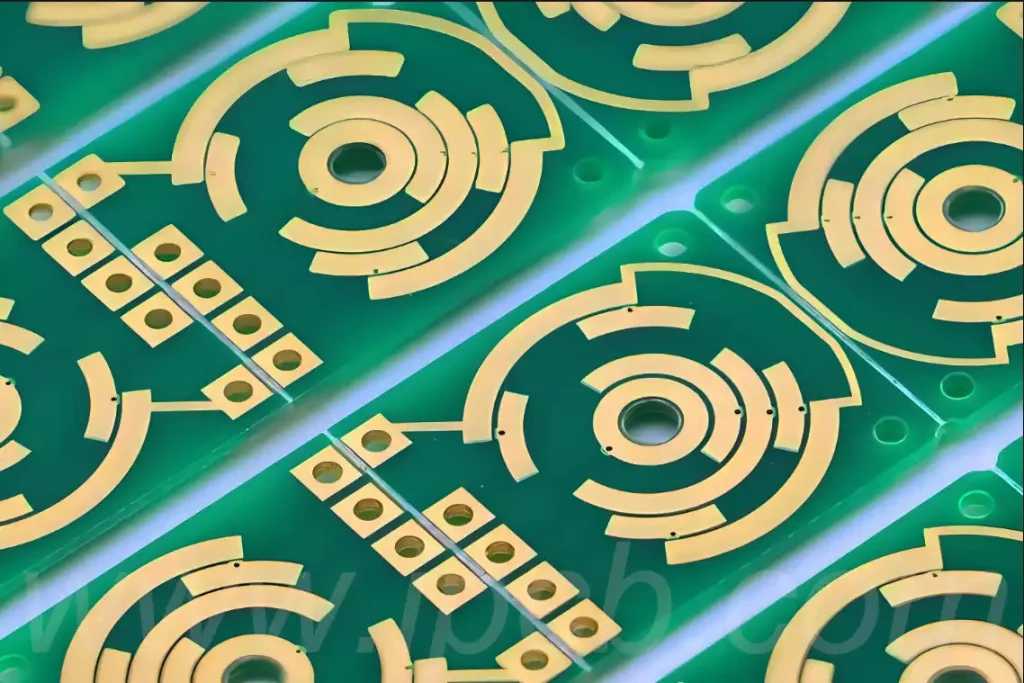

High Density Interconnect (HDI)

High Density Interconnect (HDI) is gradually becoming the mainstream of PCB design and production. This technology allows for more connections in less space, accommodating the needs of increasingly compact electronic product designs. With the miniaturization of devices, the demand for high-density, low-loss PCBs is increasing. HDI technology can effectively improve signal transmission speed and communication quality, in line with the future development requirements of 5G and the Internet of Things (IoT).

Embedded Component Technology

Embedded component technology is becoming more and more popular in PCB design, which allows components to be embedded directly inside the PCB, thus improving the functional integration of the circuit board. This approach not only reduces the size of the device, but also lowers production costs and improves signal integrity. It is expected that embedded components will become an important part of PCB design in the future and significantly improve the competitiveness of products.

Flexible Printed Circuit Board (FPCB)

Flexible Printed Circuit Boards (FPCBs) are widely used in a variety of fields due to their thinness, lightness, flexibility, and high conductivity. fPCBs are showing great market potential in fields such as smart wearable devices, smart homes, and automotive electronics. In the future, with continuous technological innovations, such as the combination of flexible and rigid technologies, FPCBs are expected to realize even wider applications in consumer electronics and medical devices.

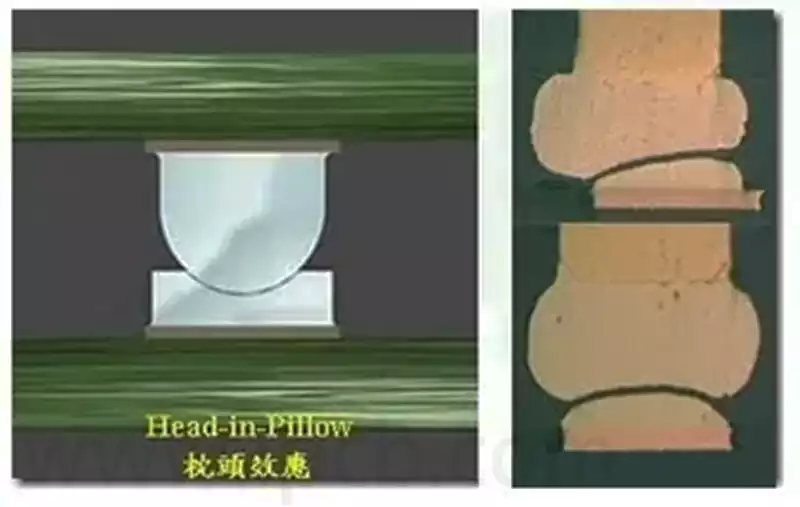

Application of environmentally friendly materials

Environmental protection and sustainable development will become an important trend in PCB manufacturing in the future. The use of environmentally friendly materials such as lead-free solder, halogen-free substrates, and biodegradable materials in the production process will become the industry standard. This move not only reduces the impact on the environment, but also enhances the social image and market competitiveness of the company. As global environmental awareness increases, the development of green printed circuit boards will have a profound impact on the development of the industry.

Intelligent and Integrated

The future of PCB design will be towards the direction of intelligent and integrated development. Intelligent PCB design requires a high degree of automation to realize seamless circuit design, simulation, verification and manufacturing to shorten the design cycle and improve reliability. Driven by the Internet of Things and artificial intelligence, the combination of smart sensors and PCBs will also become a new trend, thus promoting.