What is a flexible LED PCB? A flexible LED PCB is a circuit board that can be bent and twisted without damage. Its flexibility stems from the use of flexible plastic substrates such as polyimide, replacing the rigid fibreglass employed in traditional PCBs. This pliability makes it an ideal choice for applications with limited space or requiring adaptation to specific shapes.

Characteristics of Flexible Circuit Boards

Lightweight and Slim Profile: Compared to traditional rigid circuit boards, flexible circuit boards are significantly lighter and thinner, perfectly suited for lightweight, compact devices.

Durability: Despite their flexibility,these boards can withstand vibration and displacement, effectively reducing the risk of damage.

Versatility: Their ability to bend and twist makes them applicable across a wide range of fields, including wearable devices and medical equipment.

Advantages of Flexible LED PCBs

Space-Saving Design

The most notable advantage of flexible LED PCBs lies in their space-saving properties. Their ability to bend and conform to confined or irregular spaces enables more compact and efficient designs. This is particularly crucial in industries with limited spatial resources, such as consumer electronics and automotive.

Enhanced Durability and Reliability

Flexible circuit boards are engineered to withstand bending, making them less prone to fracture than rigid PCBs. This resilience translates into heightened reliability, vital for applications subjected to continuous motion or stress, such as wearable devices or automotive systems.

Performance and Efficiency Enhancements

Flexible LED PCBs improve performance by reducing the weight and size of electronic devices. The decrease in dimensions and mass enhances energy efficiency, as less power is required for operation. Furthermore, flexible circuit boards facilitate more effective heat dissipation, which is crucial for maintaining the performance and longevity of LED components.

Cost-Effectiveness

Although the initial manufacturing cost of flexible LED PCBs may exceed that of traditional rigid circuit boards, their long-term cost-effectiveness proves superior. Overall production costs are reduced through diminished requirements for connectors and wiring, alongside potential simplification of assembly procedures. Furthermore, their enhanced durability minimises the frequency of repairs and replacements throughout the device lifecycle.

Design Flexibility

The bending and shaping capabilities of flexible LED PCBs confer greater design freedom. Designers can transcend the limitations of rigid circuit boards to create more innovative and distinctive products. This flexibility unlocks new possibilities for product design and functionality, enabling devices once deemed unfeasible.

Applications of Flexible LED PCBs

Wearable Technology

Flexible LED PCBs are indispensable in wearable technology.Their lightweight and malleable nature makes them ideal for wearable devices requiring close body contact, such as fitness trackers and smartwatches.

Medical Devices

Medical equipment frequently requires compact, reliable, and flexible components. Flexible LED PCBs are particularly suited for applications demanding extreme precision and reliability, such as implantable devices, diagnostic instruments, and patient monitoring systems.

Automotive Industry

Within the automotive sector, flexible LED PCBs are extensively used in dashboard displays, lighting systems, and sensors. Their exceptional resistance to vibration and tolerance of extreme environments make them a favoured choice for automotive applications.

Consumer Electronics

From smartphones to laptops, flexible LED PCBs are increasingly prevalent in consumer electronics. Their space-saving design and durable characteristics perfectly align with consumer demand for compact, reliable devices.

While offering numerous advantages, flexible LED PCBs present several challenges and considerations:

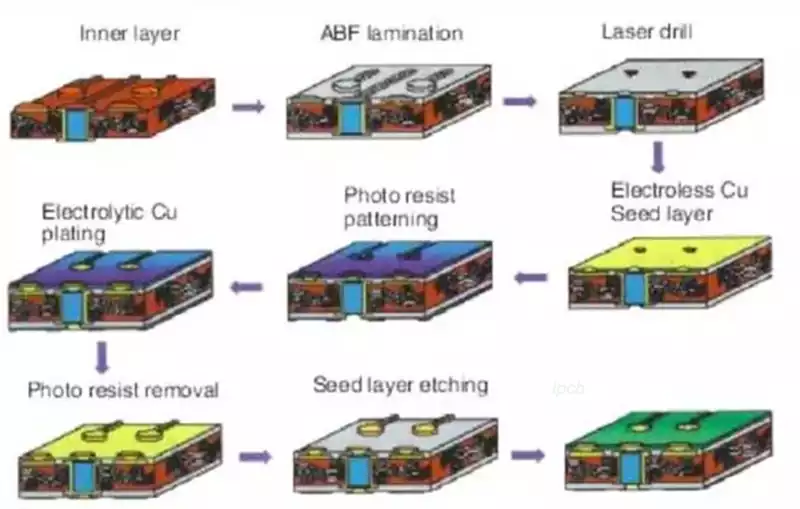

Manufacturing Complexity

The production process for flexible PCBs is more intricate than that for rigid circuit boards, potentially increasing manufacturing costs and extending lead times. However, technological advancements are continually refining these processes, facilitating broader adoption.

Design Considerations

Designing with flexible LED PCB requires meticulous planning to ensure functionality during bending or flexing. Engineers must account for factors such as bending radius, material properties, and stress points to prevent potential failures.

Material Limitations

While the materials used in flexible circuit boards are durable, they remain susceptible to damage from extreme temperatures or highly corrosive chemicals. Selecting appropriate materials and protective coatings is crucial for ensuring the longevity and reliability of the circuit board.

Flexible LED PCBs are revolutionising the electronics industry landscape with their unparalleled design flexibility, durability, and efficiency. As technology continues to advance, demand for flexible circuit boards will rise steadily, driving innovation and enabling the development of more sophisticated electronic devices. For designers and manufacturers seeking to push technological boundaries, flexible LED PCBs are an indispensable tool.