What is solder flux? Flux is a substance that helps soldering of electronic components, and at the same time protects the soldered parts and prevents oxidation. Common fluxes are rosin-based mixtures that remove oxides from the solder and the soldered surface, thereby reducing surface tension and improving solderability.

Solder flux according to its form can be divided into solid (paste), liquid and gas three. Flux generally consists of rosin, resin, halide-containing active agents, additives, organic solvents; no-clean flux is mostly liquid, consisting of rosin, resin or their derivatives, active agents, activators, group solvents, film-forming agents, etc., according to the specific needs of the composition of the proportion and quantity can be different.

How to solder with flux

- Choose the right flux: according to the different welding materials and welding methods to choose the right flux, such as steel materials, acid flux, copper materials, aluminum flux and so on.

- Master the correct operating techniques: wear protective gloves and masks when operating, maintain a dry and clean operating environment, avoid mixing other impurities and moisture, and then use the appropriate amount of flux and evenly coated to the welding parts.

- Welding temperature and time control: flux temperature is generally 300 ° C – 400 ° C, so in the welding process need to control the heating temperature and time to avoid overheating.

The use of electrical solder flux need to pay attention to safety matters

- Don’t touch the flux for a long time, so as not to cause skin allergies and other problems.

- Do not mix different kinds of flux, because it is easy to lead to chemical reaction and produce dangerous gas.

- Store the flux in a ventilated and dry place, away from sources of ignition and acidic and alkaline substances, etc., so as not to cause fire or produce harmful gases.

- Disposal of waste flux, should be in accordance with product specifications and local standards for safe handling and environmental protection, so as not to cause harm to the environment.

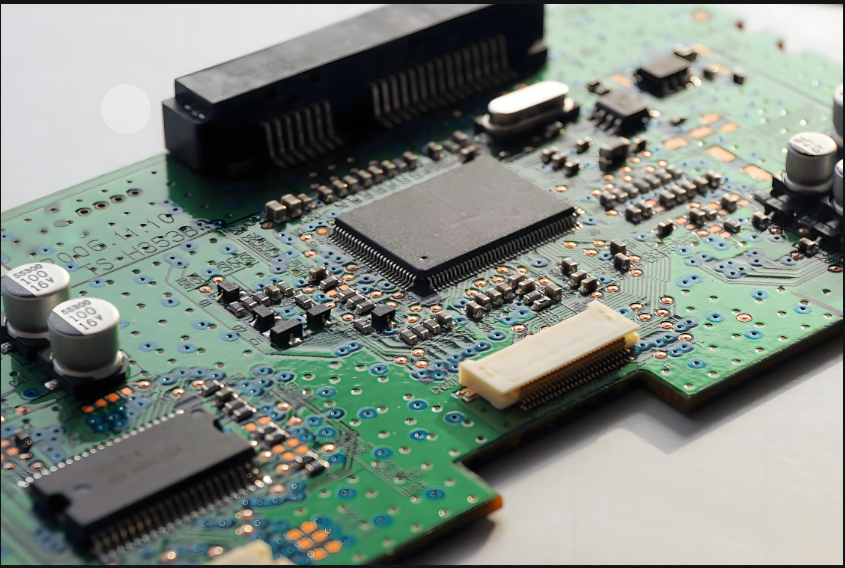

Flux residue on the PCBA (Printed Circuit Board Assembly) impact:

- Electrical performance impact: some components in the flux may penetrate into the tiny holes in the PCB board, resulting in short circuits or open circuits. This will directly affect the electrical performance of the PCBA, which may lead to the product does not work properly or intermittent failure.

- Reduced reliability: flux residue may attract dust and contaminants, forming a conductive path, which will reduce the long-term reliability of the PCBA. In addition, residual flux may be chemically altered over time, creating a corrosive effect that further affects the reliability of the PCB board.

- Increased thermal resistance: flux residue may increase the thermal resistance of the PCB board, affecting the heat dissipation of electronic components. In high-temperature environments, this may lead to increased component temperatures, affecting their stability and life.

- Appearance Impact: Flux residue may lead to poor appearance of the PCBA, affecting the quality of the product’s packaging and appearance. In some cases, this may lead to a decrease in the competitiveness of the product in the market.

- Safety issues: If flux residues contain hazardous substances, such as heavy metals or harmful volatile organic compounds (VOCs), they may cause long-term harm to human health and the environment.

- Signal Interference: In high-speed signaling applications, flux residues can cause signal interference and electromagnetic compatibility (EMC) problems, affecting product performance and stability.

Solder flux plays a key role in electronic soldering, and their proper use can significantly improve soldering quality. However, we also need to pay attention to their safe use and environmentally friendly handling to ensure production safety and environmental protection.