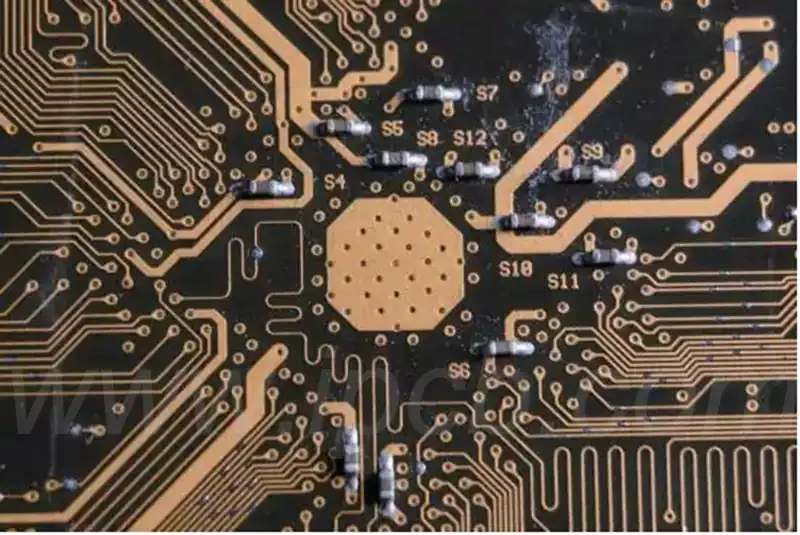

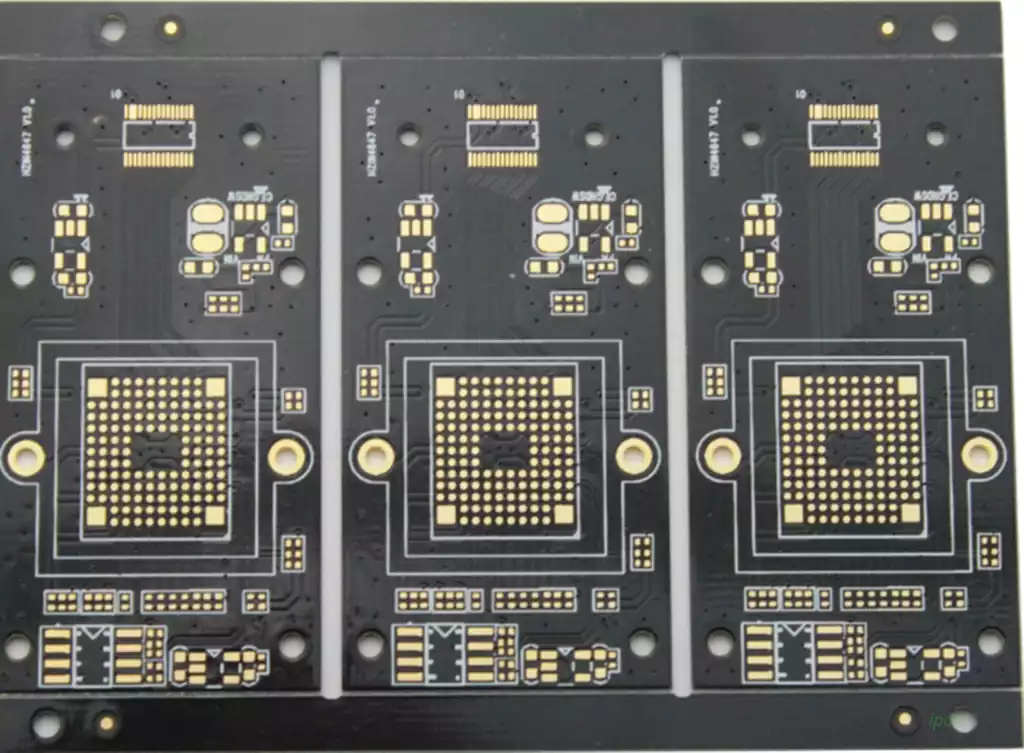

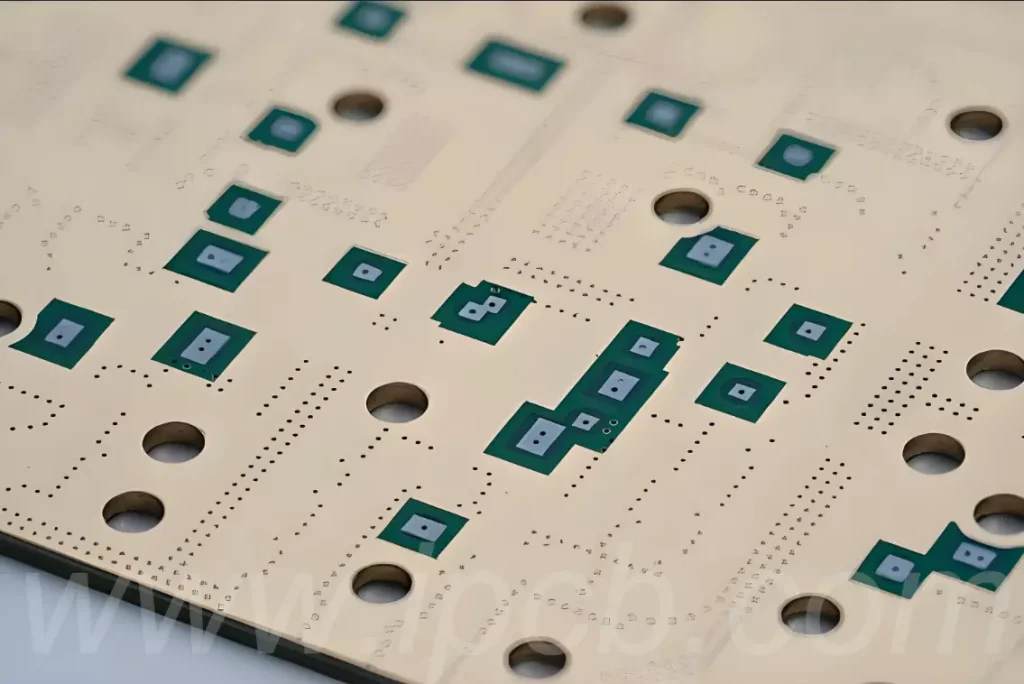

Double sided ceramic pcb board, also known as double sided ceramic circuit board, is commonly found in many electronic products that are used on a daily basis. While single-sided ceramic circuit boards have a conductive surface, double sided ceramic pcb boards have a conductive layer on each side. Compared to single-sided ceramic circuit boards, an additional layer of conductive copper is added. This extra layer allows designers to implement circuits on both sides of the ceramic circuit board, thereby increasing circuit density.Electronic components can be soldered to both the top and bottom layers of the ceramic pcb board.

Double sided ceramic pcb boards offer a practical circuit design solution because they provide higher circuit density than single-layer ceramic circuit boards, while being more cost-effective and easier to manufacture than multilayer ceramic circuit boards. They are used in a wide range of electronic applications.

Why Double sided ceramic pcb boards

The cost of producing ceramic pcb boards is heavily influenced by the complexity of the manufacturing process, and the number of layers on the board is a critical complicating factor in the design and manufacturing process.The choice of Double sided ceramic circuit boards offers a number of advantages for electronic products.

Increased Design Flexibility: In specific application scenarios,it may be necessary to use specific materials to meet certain environmental conditions, such as those suitable for high frequency applications or high temperature environments. However, using these materials for multilayer boards can be challenging. In contrast, Double sided ceramic circuit boards can be easily manufactured using a variety of different materials.

Miniaturisation of board size: By adding additional conductive layers to ceramic boards, the density of the circuitry can be significantly increased. This means that electronic components can be placed on both the front and back of the board, thus reducing the size of the boards used in electronic devices.

More cost-effective: Ceramic circuit boards can fail during production,and these failures can add extra costs. However, manufacturers have gained a great deal of experience in the production of double sided circuit boards,so that the failure rate of double sided circuit boards is relatively low compared to more complex designs.

Wide variety of applications: In advanced electronic applications,higher circuit densities are often required.Although the circuit densities offered by Double sided ceramic pcb boards are medium, they are suitable for both high-end and simpler projects.

Demonstrating excellent versatility: In some circuits, ceramic pcb boards may be required to take on the function of absorbing or supplying current, or they may need to interact with other devices in order to realise the effect of current transmission or shielding. In such cases, Double sided ceramic pcb boards can be extremely useful. The bottom layer of the circuit board can be used as a grounding source to provide an effective ground and ground reference for the system.

Double sided ceramic pcb boards are mainly used in the following fields.

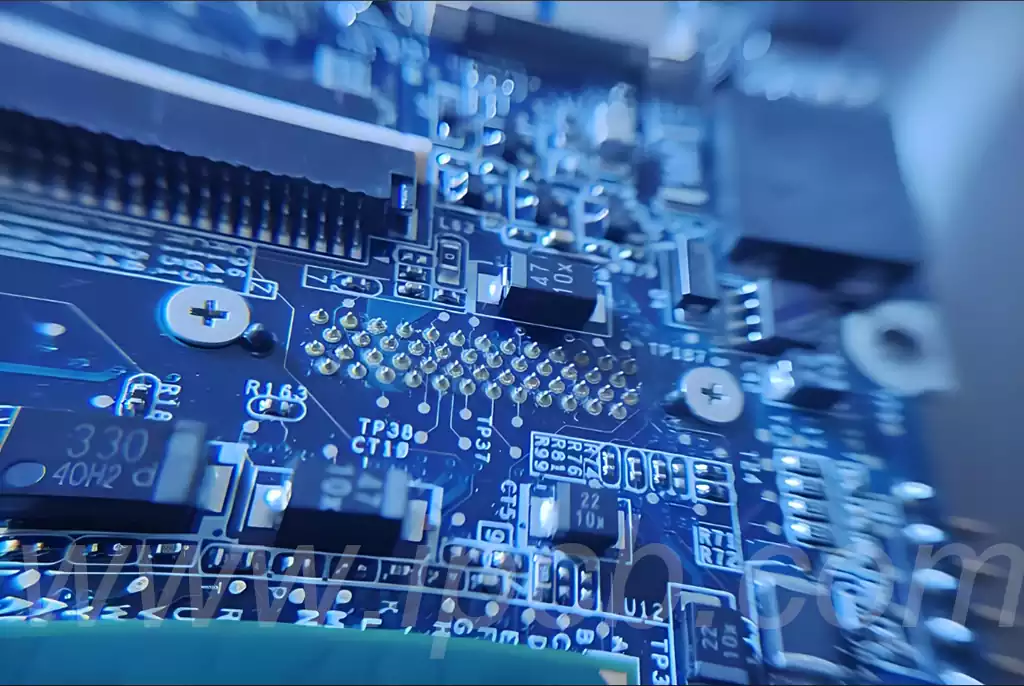

Power electronics: Double sided ceramic pcb boards are suitable for high power electronic equipment,such as power converters, inverters, power supplies, etc., and their excellent thermal conductivity and electrical properties can ensure the stable operation of the equipment and efficient energy conversion.

Automotive electronics: Various electronic control systems in automobiles, such as engine control,brake control, suspension control,etc.,require high-performance, highly reliable electronic components.Double sided ceramic pcb boards can meet these needs and improve the safety and performance of automobiles.

Communication: Modern communication equipment needs to deal with high-speed signal transmission and high-power data processing, double sided ceramic pcb boards of high thermal conductivity, high electrical performance,as well as miniaturisation and lightweight features, so that it is suitable for communication equipment, such as routers, switches, base stations and so on.

Aerospace: Aerospace electronic equipment needs to withstand extreme environmental conditions, double sided ceramic pcb boards of high mechanical strength, high temperature and corrosion-resistant characteristics, so that it is suitable for the field of electronic equipment.

Other fields:In addition to the above fields, double sided ceramic pcb boards can also be used in industrial automation, medical equipment, new energy and other fields.