The main difference between PCB vs PCA is their function and application.PCB circuit boards are used as a basic component of electronic devices, providing circuit connections and mechanical support. PCA, on the other hand, mounts electronic components onto the PCB to realize the function of the electronic device. It can be said that PCB is the basis of PCBA.

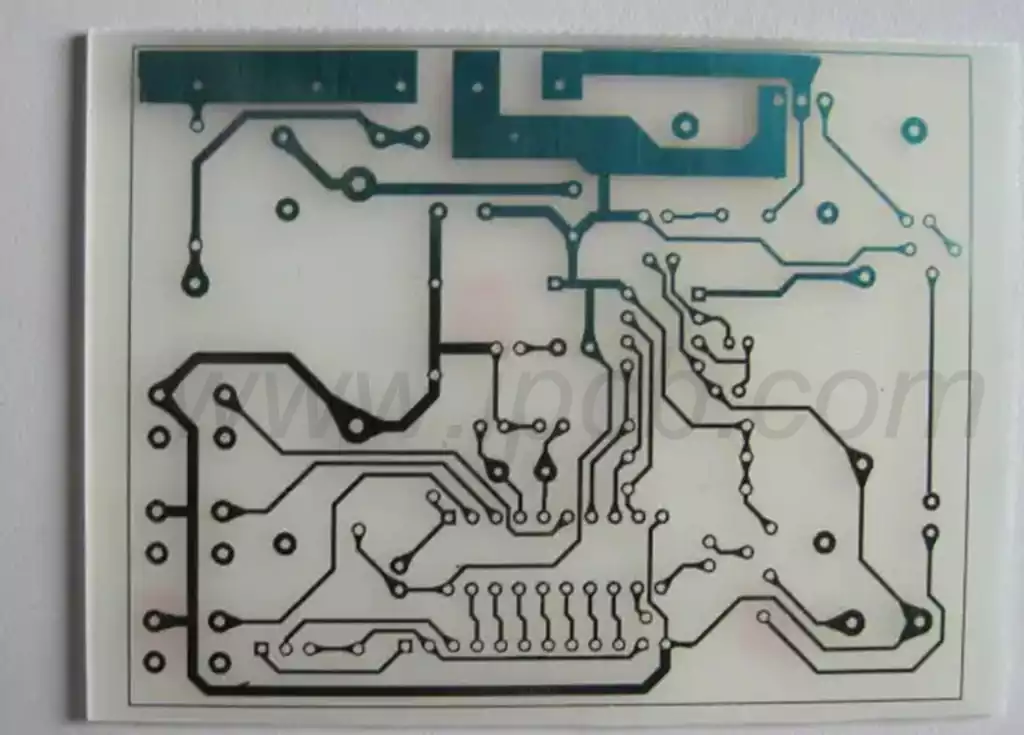

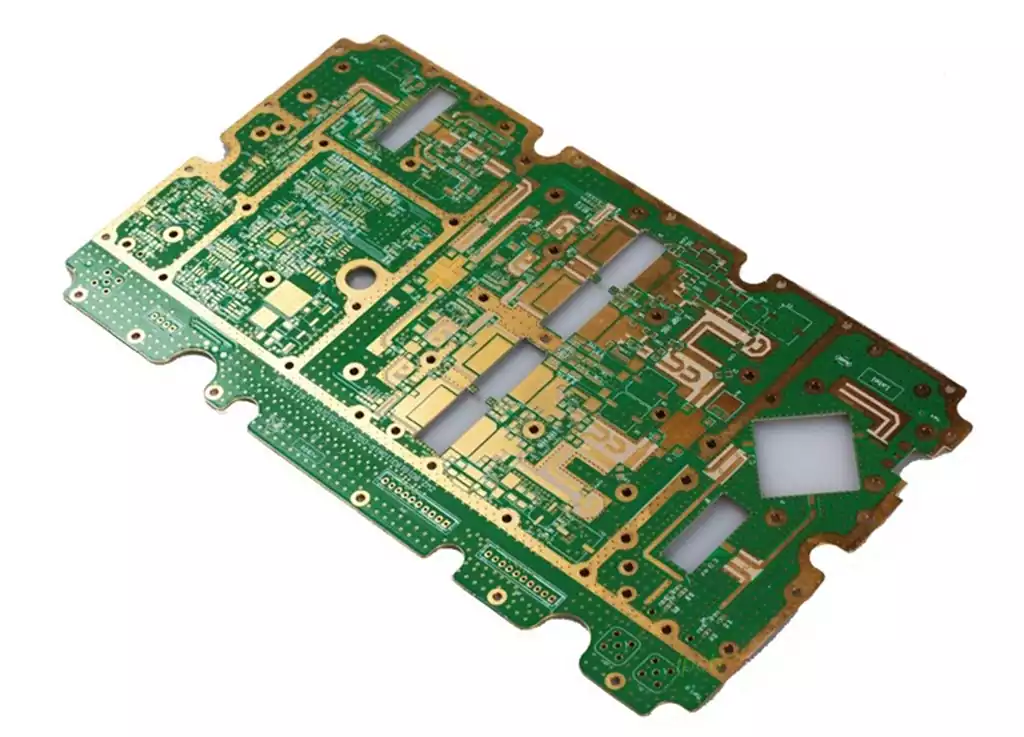

PCB, or printed circuit board, is an indispensable core component in the electronics industry. Also known as printed circuit board, is the support body of electronic components, is the carrier of electronic components electrically interconnected. Because it is made using electronic printing technology, so it is called “printed” circuit boards.It is a board-shaped components, the use of electronic printing technology to generate conductive patterns on the insulating substrate to establish electrical connections and functions.Factors such as the number of layers, structure, and material can be used to categorize circuit board. Frequently used are single sided, double sided,multilayered,flexible,etc.PCBs are circuit boards that are manufactured and processed according to printed wiring board engineering drawings.PCB boards are usually made of insulating materials such as fiberglass, ceramics, or plastics and have conductive paths that are referred to as circuits.Circuits on a circuit board can be implemented through layers of copper foil,which are etched into the desired shapes and connections.PCBs are made of a variety of materials,including copper,ceramics,ceramics, and plastics.They are also made of a variety of materials, including copper, ceramics, ceramics, and plastics.

Characteristics of printed wiring boards:

With extremely high wiring density, making electronic devices more compact and lightweight. This miniaturization design trend not only meets the modern consumer’s pursuit of portability, but also promotes the wide application of electronic devices in many fields.

Through standardized design, errors during wiring and assembly are reduced, thus saving time for equipment maintenance, debugging and inspection. This not only increases productivity but also reduces the cost of manufacturing electronic devices.

The wide range of applications has facilitated the development of mechanized and automated production. This production method not only improves productivity, but also makes electronic equipment more affordable, so that more consumers can enjoy the convenience of technology.

The flexibility of printed circuit board design makes the interchangeability of electronic devices possible. Through standardized design, different models of electronic equipment can be easily replaced and upgraded, providing users with more choices.

PCBA is the English abbreviation for Printed Circuit Board Assembly, that is to say, the PCB empty board through the SMT on the pieces, or through the DIP plug-in the entire process, referred to as PCBA.This is a common way of writing in the country, and in Europe and the United States the standard way of writing is PCB ‘A, added “‘”, which is called the official idiom.And PCA is equivalent to PCBA, more in Hong Kong, Taiwan and Europe and the United States industry people said in the mouth.

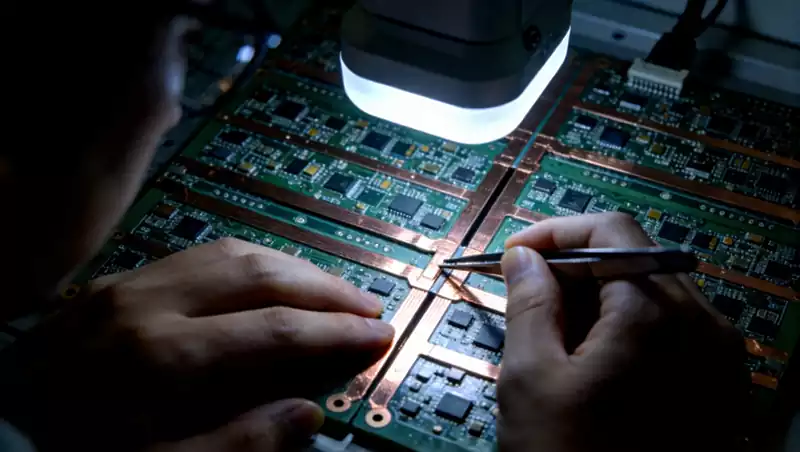

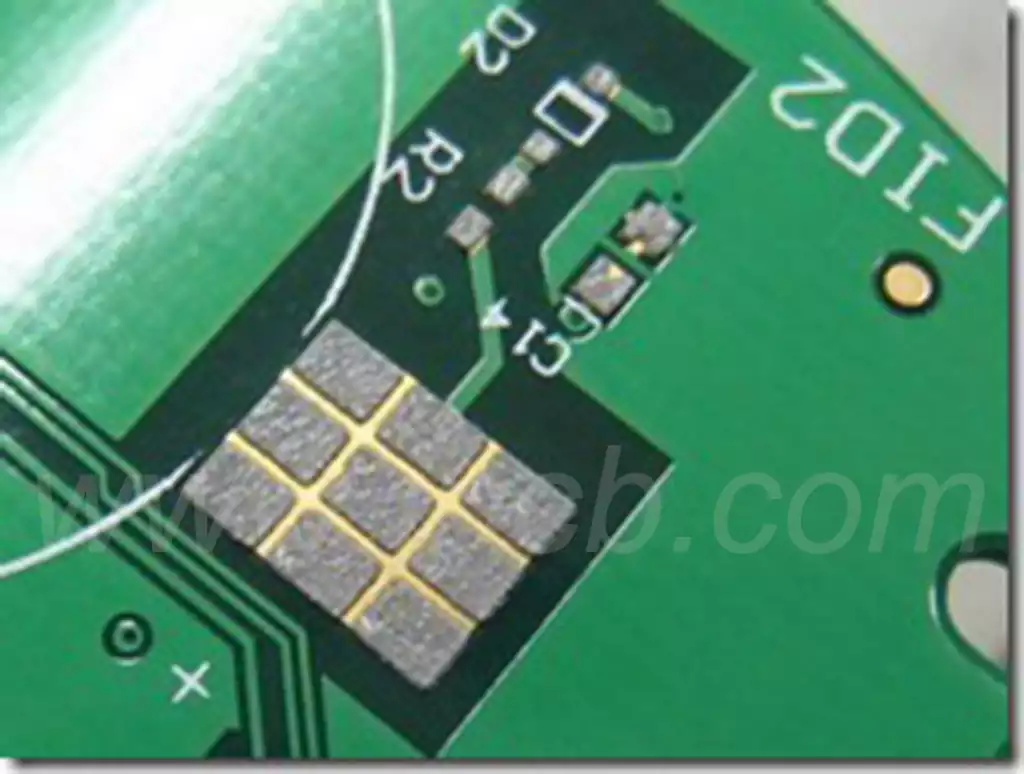

PCA is the subsequent processing of printed circuit boards, including SMT mounting and DIP insertion. SMT mounting utilizes a placement machine to accurately attach tiny parts to the PCB board, while DIP insertion applies to parts that are larger in size or unsuitable for the mounting technique. The main difference between the two methods is that SMT mounting does not require drilling holes in the PCB, while DIP insertion requires inserting the PIN pins of the part into the drilled holes. pCBAs are an important part of electronic products, controlling their functionality and quality. A board with electronics already attached to it is made into a complete electronic product when the enclosure is installed and the program is adjusted.

PCB vs PCBA production process

The process of making both PCB boards and PCBA includes the following major steps:

Design: Firstly, the circuit diagram of the printed circuit board or PCBA needs to be designed according to the requirements of the product. The designer needs to consider the layout of the circuit, the selection of components, the characteristics of the circuit and other factors.

Plate making: the pcb vs PCA board is made according to the circuit diagram.This step requires the use of CAD software for plate-making design, and then use chemical etching or mechanical etching and other methods to produce the desired board.

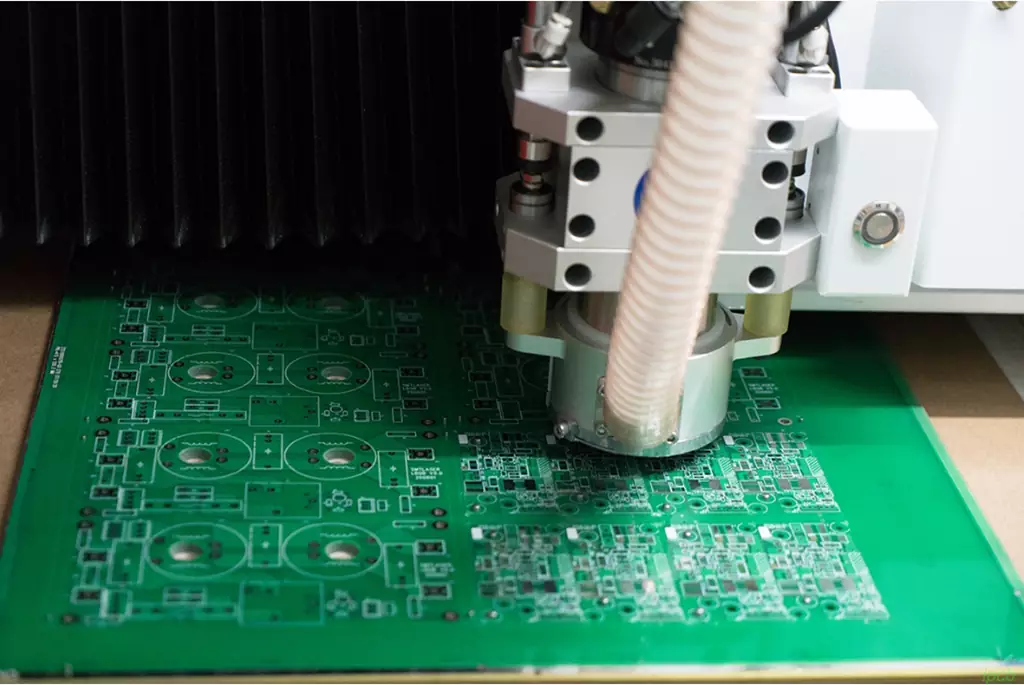

On pieces: the components will be automated on pieces, this step is generally carried out using SMT technology.

Plug-in: for the need to use plug-in components, it is necessary to plug-in process, plug-in process generally use DIP technology.

Welding: components and PCB boards or PCA boards for welding to complete the circuit connection. Generally use reflow or wave soldering technology.

Testing: After completing the welding, the PCB vs PCA needs to be tested to ensure that the circuit works properly.

Packaging: The tested printed wiring board or PCA needs to be packaged for subsequent storage and transportation.

The main difference between PCB vs PCBA lies in their functions and applications.PCB boards are used as the basic components of electronic devices, providing circuit connections and mechanical support. PCBA, on the other hand, mounts electronic components onto the PCB to fulfill the functions of the electronic device. It can be said that PCB is the basis of PCBA.

Function is different: PCB is mainly a physical carrier of electronic circuits, while the PCBA board is a fully functional electronic device containing a variety of components and connections.

The process is different: the manufacturing process of PCB boards mainly involves the design and production of circuit patterns, while PCA boards, in addition to the process of PCB boards, also includes the procurement of components, welding and testing steps.

Different applications: PCB boards are widely used in various fields as the basis of electronic circuits, while pcas are directly applied to specific electronic devices, such as cell phones, computers, home appliances and so on.

Different complexity: PCBA boards have higher complexity compared to PCB boards. On the PCBA board, various components need to be laid out and soldered according to specific rules, and the circuit connection between components needs to be considered.

As the carrier of electronic circuits, PCB lays the foundation of electronic equipment; while PCA realizes the complete function of electronic equipment by integrating components. The two complement each other and jointly promote the development of the electronics industry.