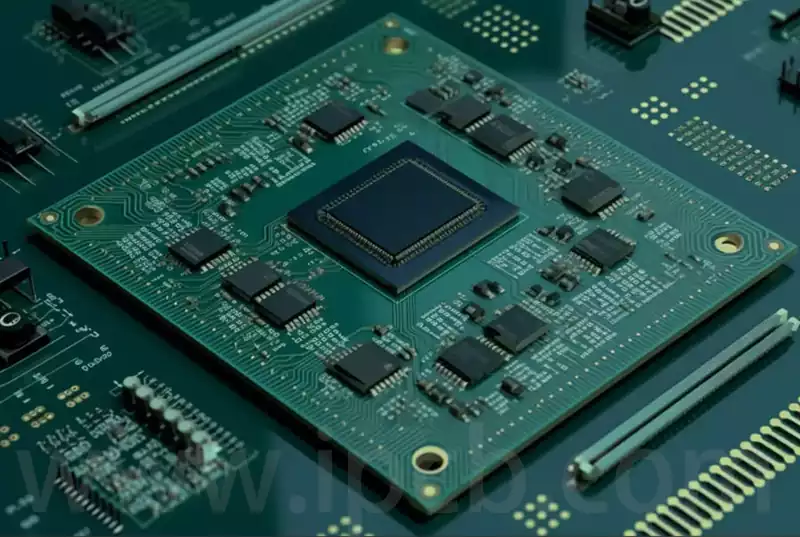

Waterproofing electronic circuit boards means that the environment around and within water can prevent the equipment from being damaged by moisture or immersion in water. Generally, the waterproofing of circuit boards is realized by applying waterproof coatings. At the same time, in the design and installation of circuit boards, it is also necessary to consider the environment in which the circuit board is located and take certain measures, such as the use of waterproof connectors.

The reasons for circuit boards to be triple-proofed include:

- Protect electronic components: dust, water and shockproof can protect the internal electronic components from the external environment, to avoid dust, moisture or vibration lead to short circuit or damage.

- Improve stability: The three-proof design can improve the stability of circuit boards and equipment to ensure that the equipment works properly in harsh environments, reducing failure rates and maintenance costs.

- Extend the life: effective dust, water and shockproof measures can extend the life of the circuit board and equipment, reduce replacement costs, enhance product reliability and durability.

Circuit boards of the three main role of defense include:

- Dustproof (Dustproof): to prevent dust from entering the circuit board, to avoid dust caused by short circuits or affect the performance of electronic components, to improve the reliability and life of the equipment.

- Waterproof (Waterproof): to protect the circuit board from moisture, to prevent short circuits or corrosion caused by the humid environment, to ensure that the normal operation of equipment in wet conditions.

- Shockproof (Shockproof): reduce the impact of mechanical vibration on the circuit board to prevent vibration caused by loose connections or damage to ensure the stability of the equipment in the mobile or vibration environment.

How to waterproof a circuit board processing methods

- Covering coating

In the circuit board surface covered with a layer of waterproof coating is a simple and easy way to deal with. Waterproof coating can choose carbon fiber, silicone and other materials, but also according to the actual need to choose the color and hardness. When choosing a waterproof coating, you need to consider the coating’s temperature resistance, hardness, adhesion and chemical resistance and other parameters. - Encapsulation

Encapsulation is a more common way of waterproofing circuit boards. In the production of circuit boards, circuit boards can be encapsulated in the mold, adding waterproof material in the encapsulation material, so that the circuit board becomes a whole, so as to achieve waterproof effect. Generally, the encapsulation material can be can shell alloy, organic silicone and so on. This treatment method is not only good waterproof effect, but also can increase the sturdiness of the circuit board. - Gluing

Gluing is a relatively simple way to waterproof circuit boards. Can use epoxy resin, silicone and other materials on the surface of the circuit board to impose a layer of thickness of not more than 1mm of glue, thus playing a waterproof role. Compared with covering the coating, its waterproof effect is better, but also can increase the shock resistance of the circuit board. - Waterproof Sleeve

The waterproof sleeve is placed in a closed casing to prevent moisture penetration. Sleeving can choose from different materials such as silicone sleeve, PVC sleeve, heat shrinkable sleeve and so on. Although the waterproofing effect of the waterproof sleeve is good, but in the use of the circuit board needs to pay attention to the heat dissipation problem. - Potting waterproof method

Potting waterproof method is to put the circuit board in the waterproof potting agent for infiltration, so that the potting agent can fill the gaps inside the electronic product to achieve the effect of waterproof. Commonly used potting agents are silicone, polyurethane, epoxy resin and so on. The advantage of this method is that the waterproof effect is good, but need to master the use of potting agent skills and amount.

Precautions for waterproofing electronic circuit boards

Material

- The substrate material of the pcb board should not use materials with high moisture content, such as wood, paper or textiles, etc., which can easily absorb water.

- The covering layer and pad part of the pcb board should not choose materials containing chloride, such as PCB boards, flame heat shrink tubes, etc., because chloride is prone to absorb water and moisture, which will lead to a decline in the insulating properties of the wire, thus affecting the service life of the circuit board.

Electronic components

- Sensitive components such as transistors, diodes, integrated blocks, etc. should not be in direct contact with water, and should be packaged in an airtight manner or use special components with better waterproof performance.

- Electronic components with connecting ends, such as sockets, key covers, etc., need to use waterproof connectors or waterproof covers to protect the connecting ends and sockets in contact with the metal part.

Connector

- The connector should adopt the connector with better waterproof performance, such as positioning pin, snap switch, etc. Avoid screw fastening connector.

- When connectors are connected to the outside world, it is necessary to use a waterproof sleeve or waterproof connector, which can effectively avoid contact between the circuit board and the outside world water, thus protecting the circuit board and its built-in components.

Waterproofing electronic circuit boards is the key to ensuring the stable operation of equipment. Through the rational selection of waterproof technology and materials, we can significantly improve the reliability and durability of circuit boards, providing a solid guarantee for the application of electronic equipment in a variety of environments.