High frequency pcb exhibits the ability to operate at higher frequencies and lower levels of signal distortion than ordinary circuit boards, despite their accompanying higher manufacturing costs and complexity.On the other hand,common circuit boards, which are known for their low cost and easy manufacturing process, are not capable of handling high-frequency circuits.This article provides an in-depth comparison of the technology base, materials used, design guidelines, and manufacturing challenges to fully characterise the differences between the two.

Technology Basis Differences

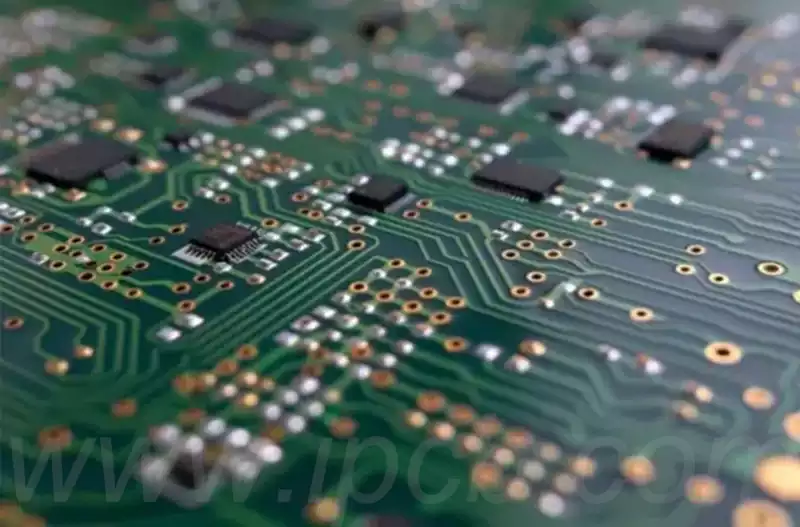

The core difference between high frequency pcb and ordinary circuit boards lies in the way they process electrical signals. High-frequency circuits process signals at frequencies in excess of 1MHz, with extremely high frequencies and fast transient response characteristics, whereas ordinary circuits are limited to low-frequency signal processing below 1MHz. High-frequency circuits have more stringent requirements for signal processing, giving high-frequency circuit boards high interconnection density and low noise and other characteristics. Therefore, high-frequency pcb needs to follow more stringent standards in design and manufacturing to ensure their proper operation.

Difference in material selection

High frequency pcb is made of high-quality materials to suit their high-speed transmission needs, such as silicone resin or polytetrafluoroethylene (PTFE) as a substrate. In contrast, ordinary circuit boards are mostly made of glass fibre, epoxy or multilayer boards. Silicones and PTFE exhibit low losses, excellent high-frequency dielectric properties and outstanding mechanical strength in high-frequency applications, whereas glass fibre and epoxy do not.

Design and Manufacturing Requirements

High frequency pcb has special design and manufacturing requirements. In order to reduce the emission of high-frequency signals and coupling, wiring should be avoided as much as possible when bending, if you need to bend, you can choose a 45-degree angle or arc turn. In addition, the wiring length should be shortened as much as possible and the distance between parallel lines should be reduced to reduce signal coupling. It is also important to reduce the use of vias (over-holes) because each one introduces a distribution capacitance of about 0.5 pF, which affects the signal speed.

Common circuit boards are relatively simple to design and manufacture. In terms of shape selection, a rectangle of similar length and width is usually used, and the four corners can be small rounded or bevelled.The thickness of the copper cladding has a great influence on the accuracy and minimum line width of the printed line.In general, the thicker the copper foil,the greater the side corrosion during manufacturing and the narrower the printed line.

Application Areas

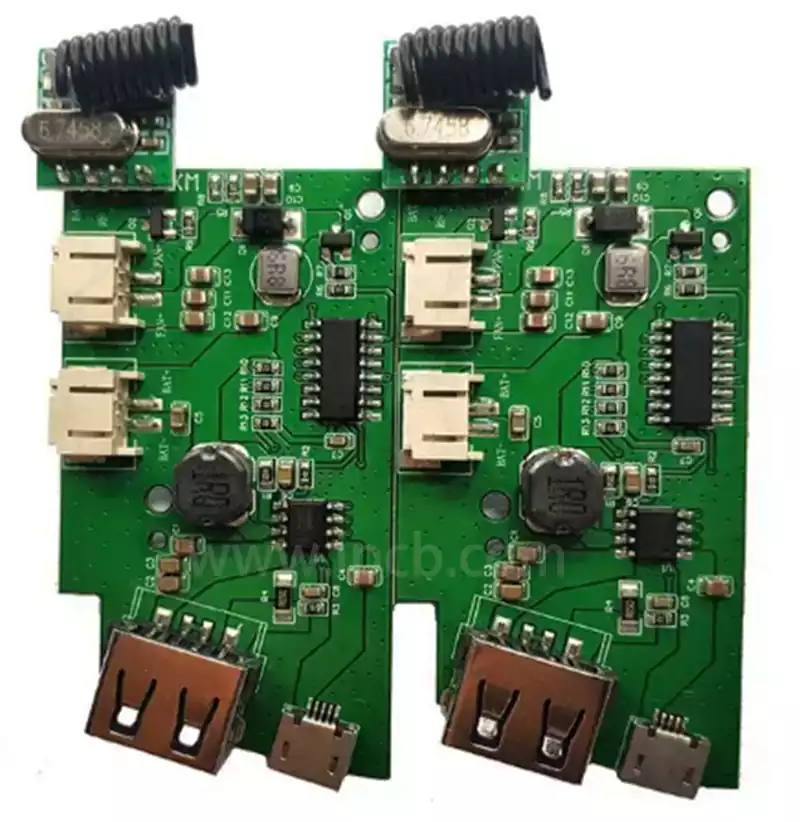

High frequency pcb is widely used in complex electronic circuits that require high speed data transmission.Its typical applications include:

Communication systems: wireless communication equipment, satellite communications and radar systems.

Military and aerospace: military radar, electronic warfare systems and aerospace equipment.

Medical equipment: medical imaging equipment and diagnostic equipment.

Test and measurement equipment: oscilloscopes, network analysers and spectrum analysers.

General circuit boards, on the other hand, are widely used in a variety of electronic devices, including:

Consumer electronics: smartphones, computers, TVs and home appliances.

Industrial equipment: industrial control systems, power supplies and measurement equipment.

Automotive electronics: engine control systems, audio systems and sensors.

LED lighting: LED bulbs and displays.

Cost Considerations

The cost of HF circuit boards is typically higher than regular circuit boards due to several factors:

Material costs: HF circuit boards use special materials such as Rogers, PTFE, etc., which cost much more than ordinary FR4 materials.

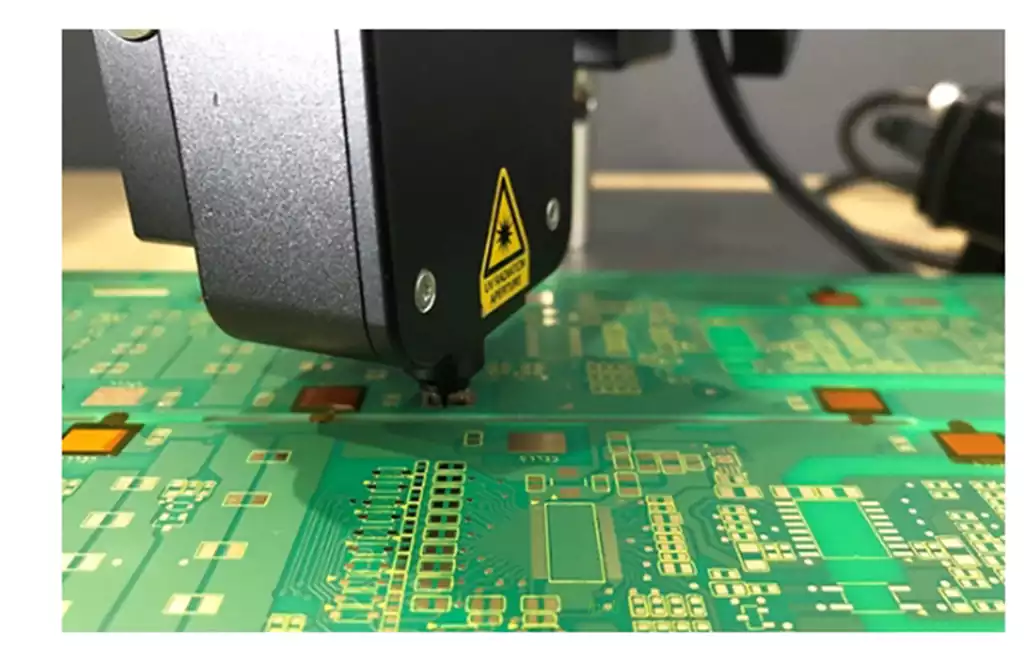

Manufacturing process: The manufacture of high frequency circuit boards requires more sophisticated equipment and stricter process control, which increases the manufacturing cost.

Design Complexity:The design of high frequency circuit boards requires consideration of more signal integrity issues, which increases the design difficulty and cost.

The relatively low cost of common circuit boards depends mainly on the following factors:

Material selection: FR4 and other common materials have lower costs.

Board size: The larger the PCB size, the higher the cost.

Number of layers: The more PCB layers, the higher the cost.

Aperture size and number: the smaller the aperture and the higher the number, the higher the cost.

Surface treatment: Different surface treatment processes have different costs, e.g. ENIG (Electroless Nickel and Gold) is usually more expensive than HASL (Hot Air Surface Levelling).

There are significant differences between high frequency pcb and conventional circuit boards.In practice,the choice of circuit board needs to be determined by the specific application requirements and cost budget. With the continuous development and innovation of electronic technology,the boundaries between high-frequency circuit boards and ordinary circuit boards may become even more blurred in the future,and the emergence of new materials and improvements in manufacturing processes will further promote the development and transformation of the circuit board industry.