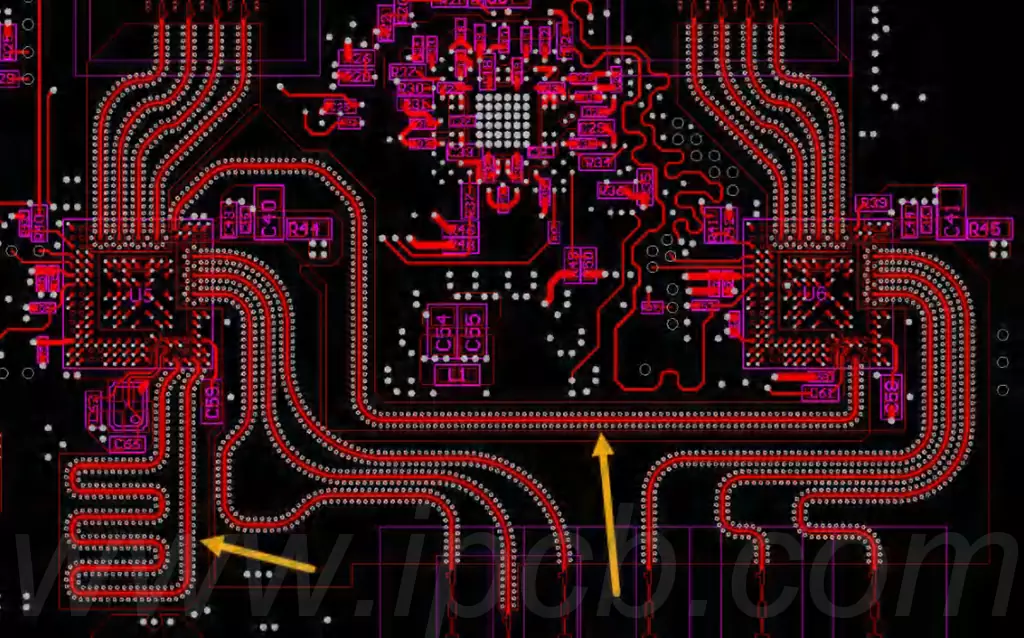

In the field of high frequency pcb circuit design, the quality of material properties directly determines signal transmission efficiency and stability. With the rapid advancement of technologies such as 5G communications, millimeter-wave radar, and industrial IoT, the demand for low-loss, high-reliability circuit materials is increasingly urgent. The RO4000® series hydrocarbon ceramic laminates, leveraging their unique material characteristics and process advantages, have become a core solution for high frequency pcb circuit design.

The RO4000® series hydrocarbon ceramic laminates and prepregs dominate the microwave and millimeter-wave high frequency pcb circuit market due to their exceptional low-loss properties and ease of processing. Compared to traditional PTFE materials, the RO4000 series not only simplifies circuit manufacturing but also delivers stable and reliable performance, making it the preferred material for high-frequency designs.

Core Advantages

Process Compatibility: Seamless integration with FR-4 manufacturing processes simplifies production workflows.

Performance Stability: Consistent dielectric constant (Dk) ensures precise signal transmission.

Efficient Thermal Management: High thermal conductivity (0.6-0.8 W/m·K) enhances circuit thermal management capabilities.

Eco-Friendly Soldering: Compatible with lead-free soldering processes, aligning with green manufacturing trends.

Low CTE Design: Low Z-axis thermal expansion coefficient safeguards high-reliability plated-through-hole quality.

Exceptional Value: Flexible Dk range (2.55-6.15) accommodates diverse design requirements while meeting UL 94 V-0 flame retardancy standards.

RO4000® LoPro® laminates utilize Rogers proprietary technology, combining reverse-processed copper foil with standard RO4000 materials to further reduce conductor loss and enhance signal integrity while retaining all advantages of the RO4000 series.This material series supports low-cost circuit manufacturing, compatible with standard epoxy/glass (FR-4) processes without requiring special preparation steps.

Key Features

Low Insertion Loss: RO4003C™, RO4350B™, and RO4835™ LoPro® laminates optimize signal transmission efficiency.

High-Frequency Support: Enables designs exceeding 40GHz, reducing passive intermodulation (PIM) in base station antennas.

Multilayer Board Capability: Supports multilayer board (MLB) designs with enhanced CAF resistance for improved circuit reliability.

Thermal Performance Optimization: Improves circuit thermal behavior for enhanced system stability.

RO4003C™ Laminate

Proprietary glass cloth-reinforced, ceramic-filled hydrocarbon material combines PTFE/glass cloth electrical properties with epoxy/glass processability. Offers consistent electrical performance across 1080 and 1674 glass cloth configurations. Rigorous process control ensures stable dielectric constant (Dk 3.38 ± 0.05) and low loss (Df 0.0027@10GHz), with a Z-axis thermal expansion coefficient of 46 ppm/°C. Suitable for multilayer board structures, featuring processing similar to FR-4 at lower cost, designed for performance-sensitive high-capacity applications.

RO4350B™ Laminate

Glass cloth reinforced, ceramic/hydrocarbon composite material, combining the electrical properties of PTFE/glass cloth with the processability of epoxy/glass. Strictly controlled dielectric constant tolerance (Dk 3.48 ± 0.05), low loss (Df 0.0037@10GHz), Z-axis thermal expansion coefficient 32 ppm/°C. Processing methods are identical to standard epoxy/glass laminates, requiring no special via treatment and offering lower cost than traditional microwave laminates. Meets UL 94 V-0 flame retardancy rating, suitable for active devices and high-power RF designs.

RO4360G2™ Laminate

Glass fiber reinforced, ceramic-filled hydrocarbon thermoset material with ultra-low loss characteristics, balancing performance and processability. The first high-dielectric constant (Dk 6.15 ± 0.15) thermoset laminate with processing similar to FR-4. Utilizes lead-free processes, offers enhanced rigidity, improves multilayer board processing, and reduces costs. Compatible with RO4400™ prepregs and low-dielectric RO4000® laminates for multilayer board designs.

RO4500™ Laminate

A cost-effective high frequency pcb laminate designed for the antenna market, fully compatible with traditional FR-4 processing and high-temperature lead-free soldering. Plated-through-hole preparation requires no special treatment, and the resin system delivers ideal antenna performance. Its affordability enables replacement of traditional antenna technologies, empowering designers to launch the most cost-effective antenna products. Dielectric constant range: 3.3 to 3.5 (+/- 0.08), loss factor: 0.0020 to 0.0037, available in large panel sizes.

RO4700™ Antenna-Grade Laminate

High-reliability, high-performance, low-cost product that replaces traditional PTFE laminates. Resin system delivers ideal antenna performance, fully compatible with traditional FR-4 and high-temperature lead-free soldering processes. Plated through-hole preparation requires no special treatment, offering high cost-effectiveness. Dielectric constant 2.55 / 3.0 (+/- 0.05), low Z-axis CTE (< 30 ppm/°C), loss tangent 0.0022 ~ 0.0029, high Tg (> 280°C).

RO4830™ Laminate

Thermoset material offering high reliability and low cost, suitable for price-sensitive millimeter-wave applications such as 76-81 GHz automotive radar sensors. Manufacturable using standard FR-4 processes, typically employed for surface-level millimeter-wave circuit design. Designed with Dk 3.24@77GHz, extremely low insertion loss (2.2dB/inch @77GHz), UL 94 V-0 flame rating, and smooth LoPro® copper foil with reverse treatment.

RO4835™ Laminate

Offers excellent stability under high-temperature conditions and significant oxidation resistance. Low-loss material enables cost-effective circuit manufacturing. Processing is compatible with standard epoxy/glass (FR-4) processes. Can be paired with LoPro® reverse-processed copper foil for applications requiring low insertion loss. Complies with RoHS standards, meets UL 94 V-0 flame retardancy requirements, conforms to IPC-4103 standards, Dk 3.48 ± 0.05, Df 0.0037@10GHz.

RO4835IND™ LoPro® Laminate

Delivers low loss and stable RF performance for 60 to 81 GHz short-range industrial radar applications. Suitable for 60-81 GHz short-range (<30m) industrial radar applications, delivering RF and interconnect stability. Designed with Dk 3.48 at 60 GHz and Dk 3.49 at 77 GHz, featuring reverse-processed LoPro® electrolytic (ED) copper foil and a glass-filled thermoset resin system.

RO4835T™ Laminate

Ultra-low loss, glass fiber-reinforced ceramic-filled thermoset material. Complements RO4835™ laminate for inner core layers in multilayer boards (MLBs). Offers high-performance material properties with an optimal balance of cost, performance, and durability. Manufacturable using standard FR-4 processes. Dielectric constant (DK) 3.3, exceptional oxidation resistance, low loss, low CTE material, UL 94 V-0 flame retardant rating.

Through technological innovation and process optimization, the RO4000® series materials provide comprehensive support for high frequency pcb circuit design, spanning performance to cost efficiency. Whether for communication base stations, automotive radar, or industrial sensors, its specialized products precisely match diverse application requirements, driving electronic manufacturing toward greater efficiency and environmental sustainability.