In high-end electronic fields such as high-frequency communications and precision sensing, the dimensional accuracy of LTCC (Low-Temperature Co-fired Ceramic) directly defines the upper limit of device performance. Even micron-level deviations can lead to circuit interconnection failure or signal transmission distortion. Pushing LTCC dimensional tolerances to the extreme is no longer a matter of isolated process optimization; it is a systematic engineering challenge that spans the entire value chain—from material preparation and forming to sintering and post-processing. Why is dimensional control in LTCC so difficult? From intrinsic material properties to production environments, which stages constitute the key levers for precision control?

Root Causes of Dimensional Deviation in LTCC

The difficulty of LTCC dimensional tolerance control fundamentally arises from its unique “ceramic–metal co-firing” process characteristics and from the physical and chemical transformations occurring across multiple process stages. From green tape fabrication to final sintering, even minor fluctuations at any step can accumulate into significant dimensional deviations, creating a chain reaction where a small change propagates throughout the system.

Uncertainty in Material Shrinkage as the Primary Challenge

LTCC green tapes are composed of ceramic powders mixed with organic vehicles (binders, plasticizers, solvents). During sintering, the organic components must completely decompose and volatilize, while the ceramic powders undergo densification—both processes result in dimensional shrinkage. The content of organic vehicles and the particle size and morphology of ceramic powders directly influence shrinkage behavior. Non-uniform particle size distribution can lead to localized shrinkage rate differences and warpage, while fluctuations in organic vehicle ratios alter volatilization behavior and overall shrinkage. In practice, LTCC sintering shrinkage typically reaches 10–20%. Accurately controlling this shrinkage is the foundation of dimensional precision.

Precision Limitations in Forming Processes as a Secondary Challenge

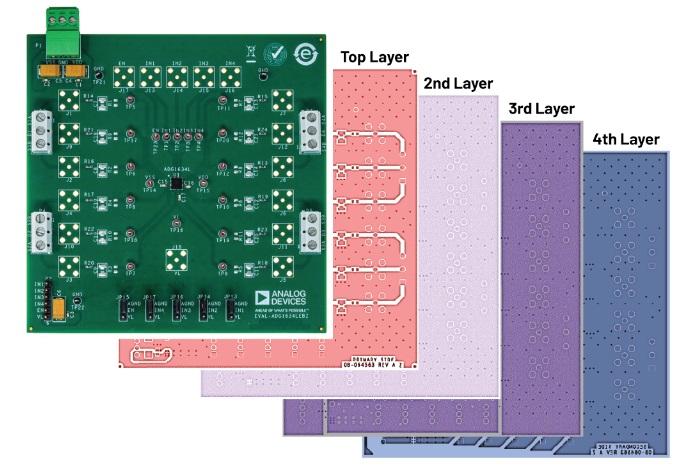

Forming processes—including tape casting, punching, via filling, and lamination—introduce multiple sources of dimensional error. During tape casting, slight variations in doctor-blade gap, carrier speed, or slurry viscosity can cause thickness deviations in green tapes. The diameter and positional accuracy of laser-drilled vias directly affect subsequent interconnection accuracy. During lamination, misalignment between layers or uneven pressure distribution can result in layer shift or global deformation after sintering.

Thermo-Mechanical Effects During Sintering as the Critical Challenge

Sintering, typically performed at 850–900 °C, is the decisive stage for LTCC dimensional stability. In addition to organic burnout and ceramic densification, LTCC must accommodate co-firing compatibility between ceramics and embedded metals (such as silver or copper). Differences in coefficients of thermal expansion between metals and ceramics generate thermal stresses during heating and cooling. If these stresses are unevenly distributed, warpage and non-uniform shrinkage occur. Moreover, temperature uniformity and atmosphere stability within the furnace directly affect shrinkage consistency across different regions, leading to dimensional variation even within the same batch.

Core Strategies for Achieving Extreme LTCC Dimensional Control

Achieving ultra-tight LTCC dimensional tolerances requires breaking away from single-process optimization and establishing a full-chain control system—from materials to post-processing—implementing closed-loop management through source control, in-process correction, and end-stage refinement.

1.Homogenization and Stability Control in Material Preparation

Materials form the basis of dimensional control. Only by ensuring homogeneity in ceramic powders and organic vehicles can shrinkage be reliably managed downstream. Ceramic powders should be processed using high-precision milling and classification techniques to achieve sub-micron particle sizes with a narrow distribution (D90/D10 ≤ 2.0), ensuring consistent flowability and sintering activity. Air classification and vacuum drying are employed to remove impurities and agglomerates, preventing localized shrinkage anomalies.

Equally critical is the precise formulation and mixing of organic vehicles. High-precision weighing equipment (accuracy up to 0.1 mg) is required to control binder, plasticizer, and solvent ratios within ±0.5%. High-shear dispersion combined with vacuum de-foaming ensures uniform mixing without bubbles or local agglomeration. After fabrication, green tapes should be stored in a controlled environment (23 ± 2 °C, 50 ± 5% RH) to prevent moisture absorption or loss that could induce dimensional fluctuations.

2.Automation and Precision Enhancement in Forming Processes

As forming is a major source of dimensional error, automation and precision alignment technologies are essential to reduce operator-dependent variability. In tape casting, high-precision servo systems control carrier speed (error ≤ 0.1 mm/s), combined with pneumatic doctor-blade adjustment to maintain tape thickness tolerance within ±1 µm. Online thickness and flatness monitoring enables real-time correction through automatic parameter adjustment.

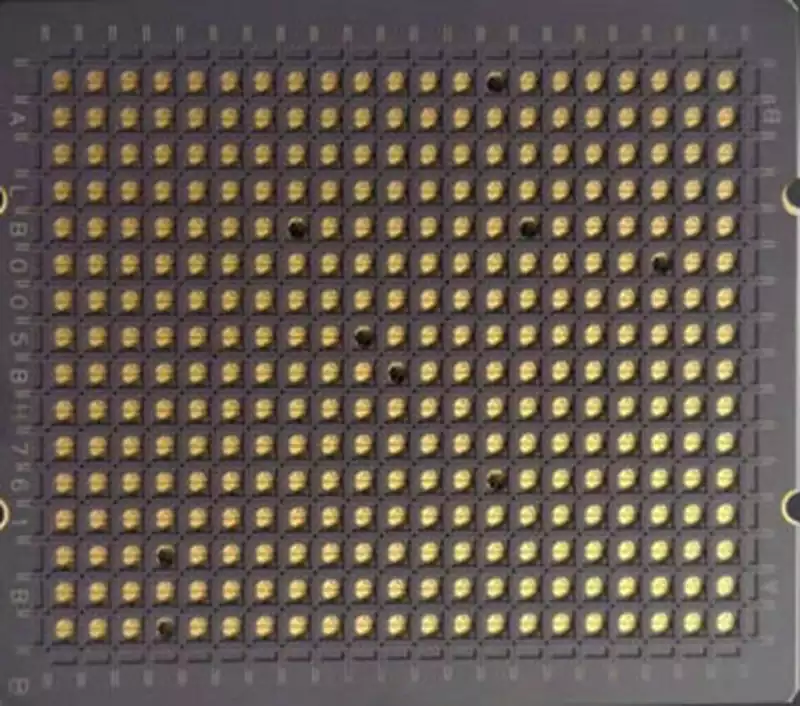

For via punching and filling, laser drilling systems equipped with high-precision galvanometers and CCD vision alignment achieve positional accuracy within ±2 µm and via diameter tolerance within ±1 µm. Via filling uses precision screen printing to control paste volume and surface planarity, avoiding protrusions or recesses that cause lamination defects. Lamination is performed using vacuum hot-press systems with pressure sensors and temperature controls to ensure uniform pressure distribution (≤ 0.1 MPa deviation) and temperature stability (≤ 1 °C deviation), while CCD alignment systems limit layer-to-layer misalignment to ±3 µm.

3.Fine and Intelligent Control of the Sintering Process

Sintering determines final LTCC dimensions. Precise control of heating rates, dwell times, and furnace atmosphere is critical to suppress non-uniform shrinkage and deformation. A segmented heating profile is typically employed:

Low-temperature stage (RT–400 °C):slow ramp (0.5–1 °C/min) to allow gradual organic burnout and minimize internal stress.

Mid-temperature stage (400–600 °C):moderate ramp (1–2 °C/min) to initiate ceramic bonding.

High-temperature stage (600 °C to peak):controlled ramp (0.8–1.5 °C/min) to ensure uniform densification.

Peak temperature (typically 850–900 °C) and soak time (30–60 min) must be precisely matched to material characteristics, with tolerances controlled within ±2 °C and ±1 min, respectively. Multi-point temperature sensing ensures furnace uniformity within ±3 °C. For atmosphere-sensitive processes such as copper co-firing, nitrogen–hydrogen ratios must be controlled within ±0.5% to prevent oxidation or abnormal sintering. Intelligent sintering simulation software can model shrinkage and deformation under different conditions, enabling curve optimization and reducing trial-and-error.

4.Precision Post-Processing and Closed-Loop Inspection

Even with stringent process control, minor dimensional deviations may remain after sintering. Precision post-processing and comprehensive inspection loops further compress tolerances. Surface grinding and polishing with diamond wheels and online thickness monitoring can control thickness within ±1 µm. Edge burrs and warpage are corrected through precision milling and thermal straightening, achieving edge perpendicularity errors ≤ 0.5 µm/mm.

A robust inspection system ensures dimensional integrity. High-precision optical metrology (resolution up to 0.1 µm) measures length, width, and thickness; X-ray inspection verifies internal circuit alignment; laser flatness measurement evaluates planarity. Detected deviations are traced back to upstream processes, enabling parameter adjustment and forming a closed-loop “inspection–analysis–optimization” system.

5.Construction of Temperature- and Humidity-Controlled Cleanrooms

Environmental factors are often underestimated. Establishing a controlled cleanroom environment minimizes dimensional variation caused by temperature, humidity, and particulate contamination. Production areas should meet Class 1000 cleanliness standards, with particle counts (≥ 0.5 µm) ≤ 3,520/m³. Temperature is maintained at 23 ± 2 °C and humidity at 50 ± 5%, with fluctuation rates ≤ 0.5 °C/h and ≤ 3%/h, respectively. Anti-static, dust-resistant materials for equipment and surfaces prevent contamination that could affect green tapes or substrates.

Digital Technologies Enabling Ultra-Precision Dimensional Control

The integration of digital technologies—AI and big data analytics—enables intelligent upgrades in LTCC dimensional control. Sensors deployed throughout the production chain collect data on material formulations, forming parameters, sintering profiles, and environmental conditions. AI algorithms analyze correlations within these datasets to identify critical drivers of dimensional deviation, predict potential issues, and optimize parameters proactively.

For example, AI-based analysis of sintering curves versus dimensional outcomes can automatically generate optimal firing profiles. Big-data analysis of batch-to-batch material variability enables adaptive adjustment of forming and sintering parameters. Digital twin technology further allows virtual simulation of LTCC processes, predicting dimensional behavior under different conditions and reducing physical trial-and-error. This shifts dimensional control from reactive correction to proactive prediction.

Pushing LTCC dimensional tolerances to the extreme is a comprehensive demonstration of technical capability and refined process management. From homogeneous material preparation and automated forming to intelligent sintering control, every precisely managed step contributes to final dimensional accuracy. As materials science, automation, and digital technologies continue to converge, LTCC dimensional control will advance beyond the micron scale toward sub-micron precision.