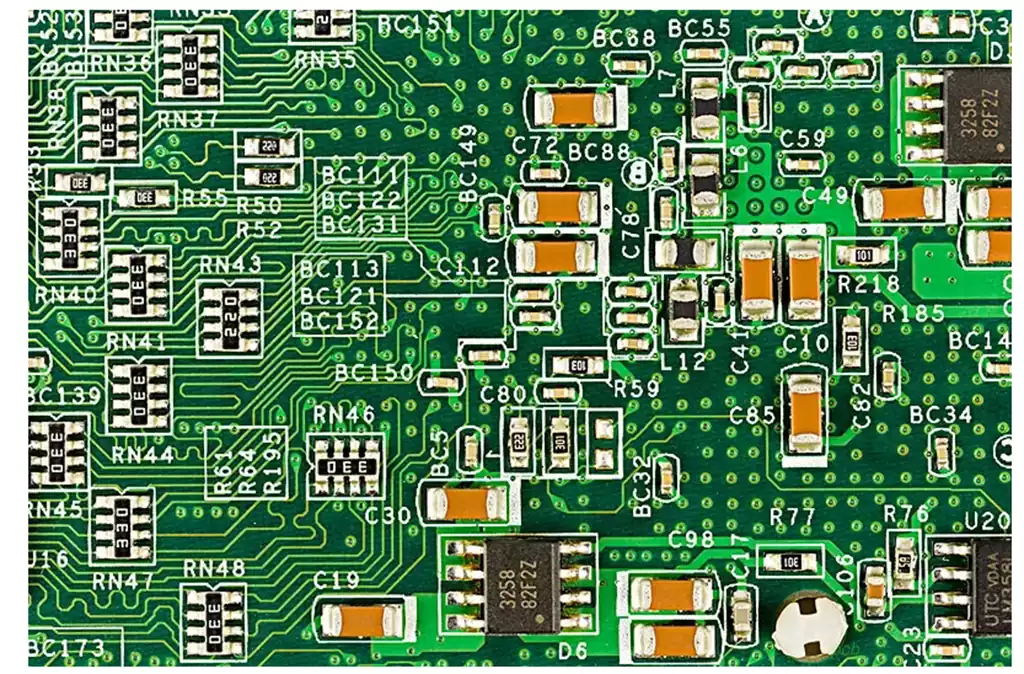

Through-hole assembly, also known as through-hole technology, is a mounting method for electronic components. It consists of inserting components into existing holes in printed circuit boards (PCBs) using the component’s pins and soft brazing of electronic components by hand assembly or automatic insertion loaders.

Advantages of through hole assembly

Through hole assembly technology, or THT for short, occupies an indispensable place in electronics manufacturing. Its advantages include:

Easy prototyping: Through-hole components are easy to replace, a feature that makes them ideal for PCB prototyping and testing.

Excellent heat resistance: THT bonds have excellent heat resistance, a benefit that makes them highly desirable for aerospace and military products.

Strong power handling: The soldering process for through-hole assemblies creates a solid bond between the board and the assembly, making it ideal for large assemblies that may be subject to significant impact.

Robust Physical Connection: The leads of through hole assembly is designed to have excellent physical endurance to withstand a variety of environmental stresses. Since the leads are soldered through the circuit board, this solid physical connection makes THT technology the preferred choice for stadium and billboard LED light production. It is also widely used in industrial equipment and machinery to cope with harsh working environments.

Limitations of through hole technology

Increased PCB size and cost: THT requires drilling holes in the PCBA, resulting in increased board size and associated costs. The drilling process also affects total production time.

Lower component density: Due to the need for drilling and the size of the components, THT cannot match the component density offered by surface mount technology, limiting its potential for miniaturisation.

Difficulties with fine pitch components: THT cannot handle components with tiny leads or closely spaced leads (fine pitch components), limiting its compatibility with some modern electronic components.

Through-Hole PCB Assembly Technology

1) Manual Through-Hole Assembly

Manual assembly, also known as manual soldering, is not suitable for boards with smaller sized electronics, as the tiny size of these boards makes it difficult to achieve accurate soldering by hand. However, for larger size components, such as through-hole chip packages and LED resistors, manual assembly is still more effective. It should be noted, however, that manual through-hole assembly is slow, making it difficult for a single operator to solder a large number of components, such as 500 or more, in a short period of time. As technology advances, lead-free solders have replaced earlier low-melting-point solders, which have a higher melting point and make manual soldering more difficult. During the soldering process, prolonged use of soldering iron to wet the solder and solder spreading phenomenon will increase the difficulty of soldering. At the same time, due to the small size of the component boundary, must ensure that the components in the solder before solidification to prevent damage to remain intact.

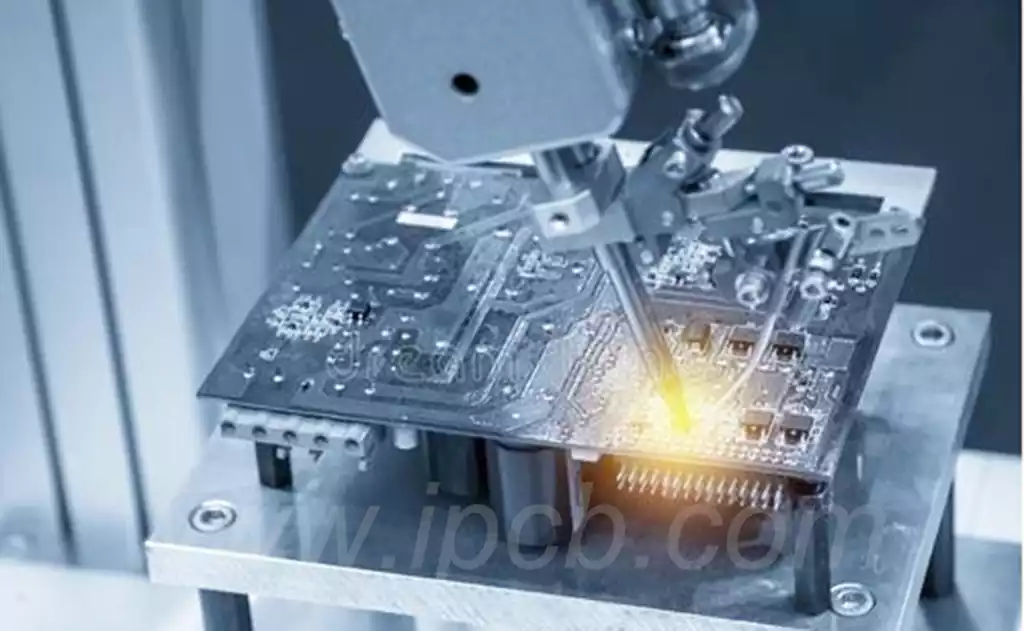

2) Automated Through-Hole Assembly

In contrast, automated through-hole assembly has obvious advantages in terms of efficiency. When all the components are placed sequentially on the conveyor belt, automated equipment can be completed in one hour more than 500 components of the solder paste coating and soldering operations, and good consistency of the solder joints, stable quality, significantly better than the level of manual soldering.

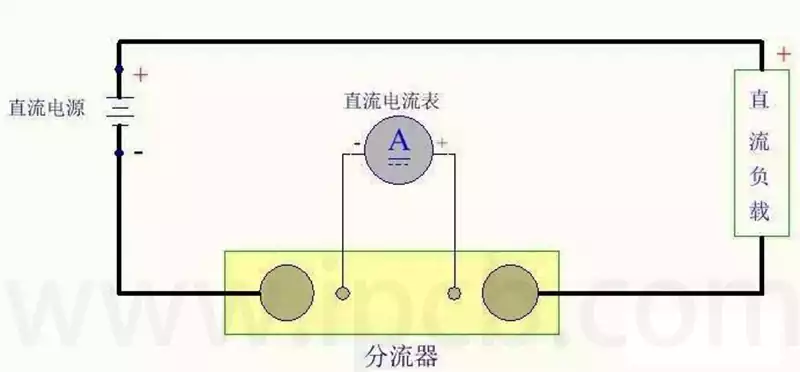

SMT and THT technologies have their own merits in terms of process principles, equipment requirements, assembly efficiency and quality. When choosing a suitable electronic assembly method, it is necessary to comprehensively consider various factors such as product requirements, production environment and cost-effectiveness.

SMT technology stands out for its outstanding reliability and stability. Thanks to the small size of the components used, the connection to the printed circuit board is much tighter, which ensures good electrical performance. In addition, SMT connections have low thermal stress, a feature that is particularly noticeable in high-temperature environments and contributes to the overall performance of the product. It is worth noting, however, that due to their tiny size, SMT components are susceptible to mechanical stress and may face challenges in high-vibration or high-shock environments.

In comparison, THT technology is slightly less impressive in some respects. While the larger size of its components makes them more susceptible to mechanical stress, the connecting parts are susceptible to thermal stress. However, for high power and high voltage applications that need to handle high currents and have high heat dissipation capabilities, THT technology shows its unique advantages.

In terms of design flexibility, SMT technology is clearly superior. Its double-sided assembly capability allows for more compact electronic products that meet the high space requirements of modern electronic devices. However, on the other hand, the skills required of the designer are also correspondingly higher, and at the same time, the compatibility of some special components, such as high-voltage and high-power components, is relatively poor.

Through-hole assembly and surface mount technologies have their own advantages and disadvantages, and it is important to choose the right assembly method for different applications and environments. Through-hole technology, with its strong physical connection and excellent heat resistance, is suitable for high power, large or harsh environment electronic components, while surface mount technology is known for its high density, small size and design flexibility, to meet the pursuit of modern electronic products for thin and light!