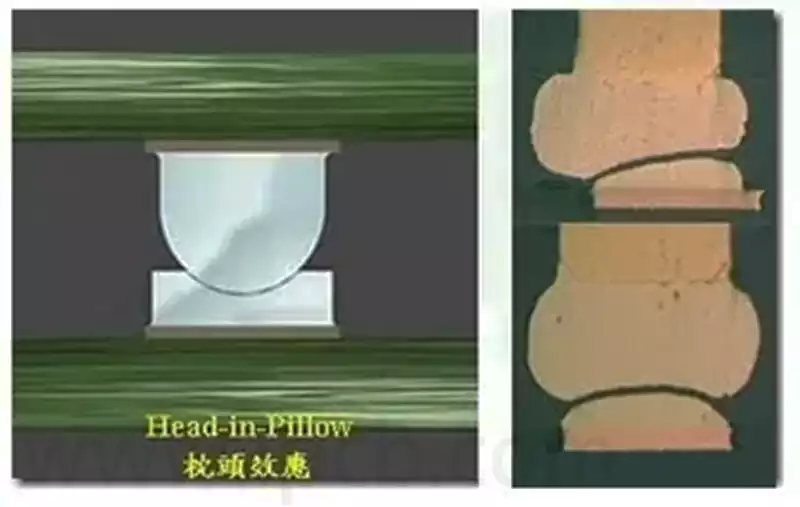

Principle and Prevention of Pillow Effect on Solder Joints

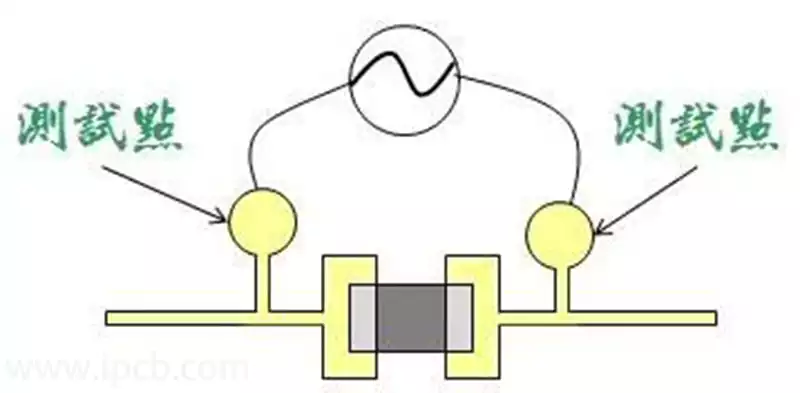

Solder Joint Pillow, also known as the pillow effect (Head-in-Pillow, HIP), is an undesirable phenomenon in which the solder balls of BGAs, CSPs and other components fail to fully fuse with the solder, resulting in the failure to form good electrical connections and mechanical solder joints. This phenomenon is similar to the shape of a […]