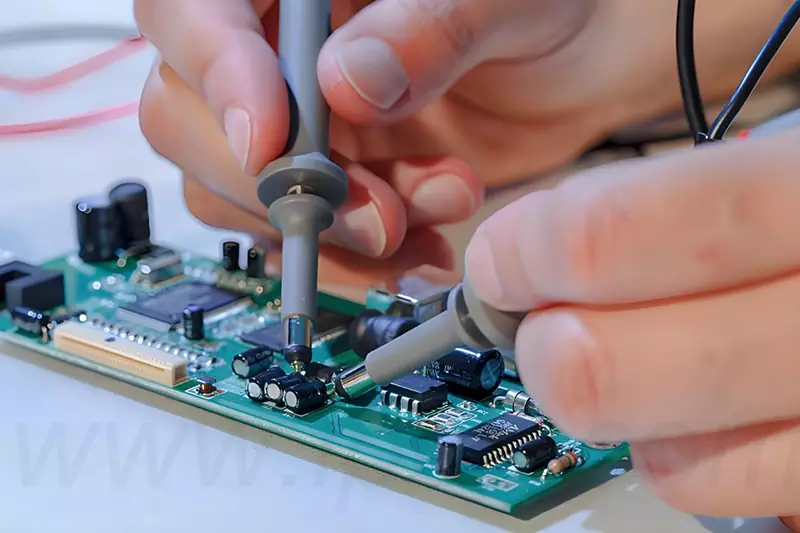

Difference between wave soldering and reflow soldering

Wave soldering, also known as surge wave soldering, is a method of forming wave-like peaks through molten solder, so that the pads and component pins on the circuit board can be soldered as they pass through the peaks of the solder wave. The core of the solder tank is continuously heated and maintain a certain […]